A method for advanced treatment of high-concentration organic wastewater

A technology for organic wastewater and advanced treatment, applied in water/sewage treatment, multi-stage water/sewage treatment, oxidized water/sewage treatment, etc., which can solve the problem that the operation results are easily affected by changes in water quality and water quantity, and the adaptability of biological treatment technology Low cost, occupied land and other problems, to achieve the effect of easy recycling and separation, preventing pollution, and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

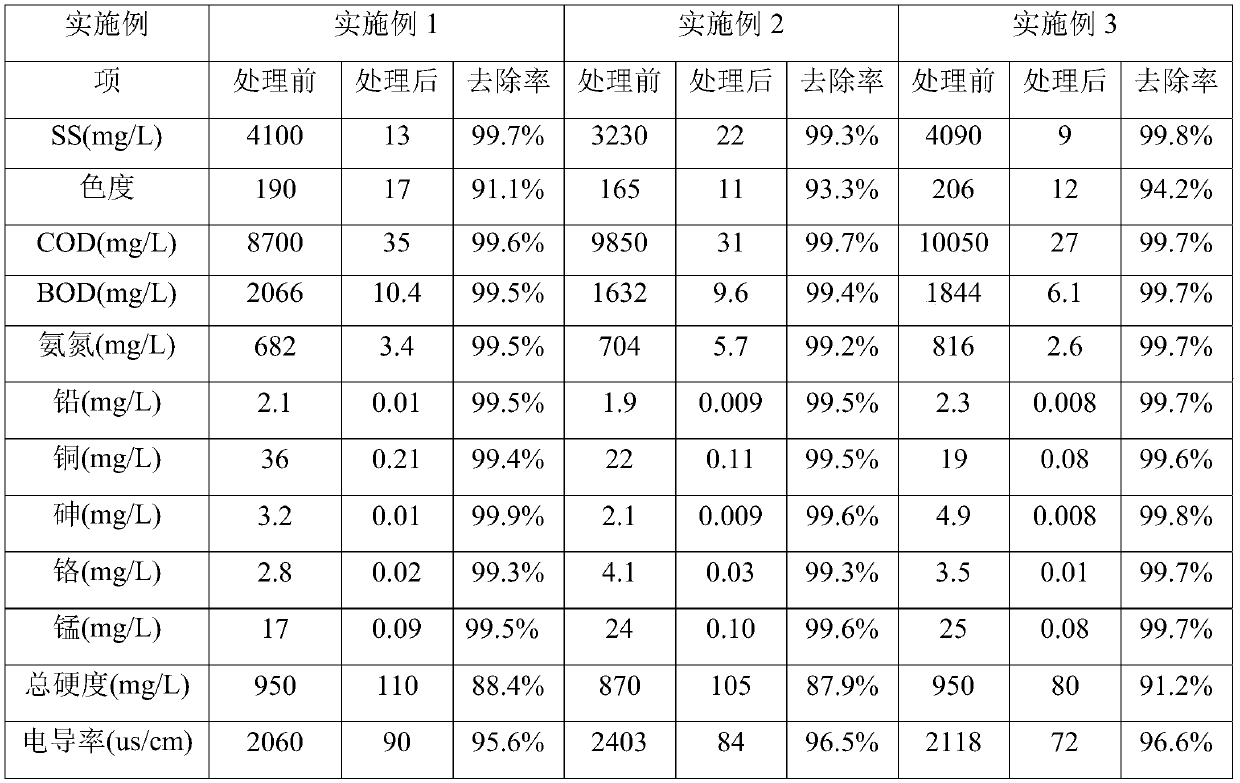

Embodiment 1

[0035] A method for advanced treatment of high-concentration organic wastewater, the method comprising the following steps:

[0036] Step 1. Coagulation and sedimentation: High-concentration organic wastewater enters the coagulation sedimentation tank through a mechanical grid, and 0.2 kg of chitosan-acrylamide graft copolymer flocculant is added to the water inlet for each ton of sewage;

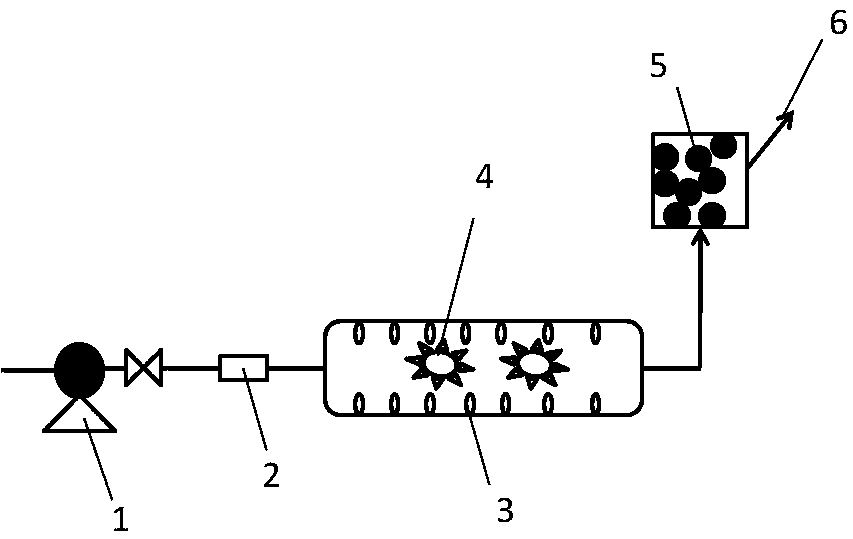

[0037] Step 2, UV-ozone-ultrasonic joint reaction section: UVU low-pressure ultraviolet mercury lamp ( figure 1 4) After the preheating is completed, the effluent of the coagulation sedimentation tank is passed into the ultraviolet-ozone-ultrasonic combined reactor ( figure 1 shown in ), start the ultrasonic array ( figure 1 Shown in 3), reflux treatment for 1h;

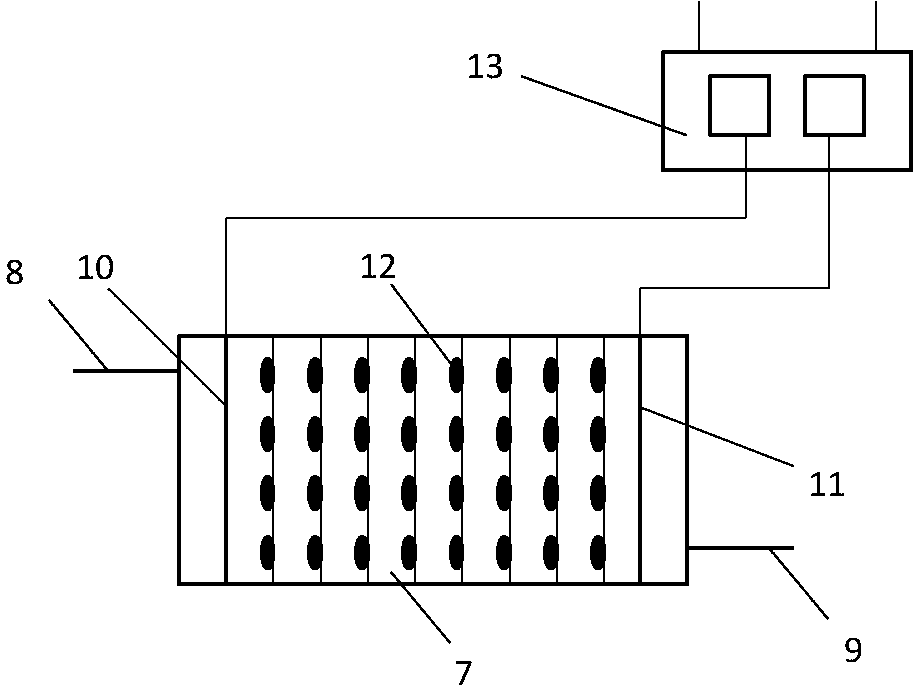

[0038] Step 3, three-dimensional electrode electrolysis treatment: the effluent of the combined reactor is passed into the three-dimensional electrode electrolysis reactor ( figure 2 7), using polypyrrole-modified platinum oxi...

Embodiment 2

[0046] A method for advanced treatment of high-concentration organic wastewater, the method comprising the following steps:

[0047] Step 1. Coagulation and sedimentation: High-concentration organic wastewater enters the coagulation sedimentation tank through a mechanical grid, and 0.4 kg of chitosan-acrylamide graft copolymer flocculant is added to the water inlet for each ton of sewage;

[0048] Step 2, UV-ozone-ultrasonic joint reaction section: UVU low-pressure ultraviolet mercury lamp ( figure 1 4) After the preheating is completed, the effluent of the coagulation sedimentation tank is passed into the ultraviolet-ozone-ultrasonic combined reactor ( figure 1 shown in ), start the ultrasonic array ( figure 1 shown in 3), reflux treatment for 1.5h;

[0049] Step 3, three-dimensional electrode electrolysis treatment: the effluent of the combined reactor is passed into the three-dimensional electrode electrolysis reactor ( figure 2 7), using polypyrrole-modified lead oxide...

Embodiment 3

[0057] A method for advanced treatment of high-concentration organic wastewater, the method comprising the following steps:

[0058] Step 1. Coagulation and sedimentation: High-concentration organic wastewater enters the coagulation sedimentation tank through a mechanical grid, and 0.8 kg of chitosan-acrylamide graft copolymer flocculant is added to the water inlet for each ton of sewage;

[0059] Step 2, UV-ozone-ultrasonic joint reaction section: UVU low-pressure ultraviolet mercury lamp ( figure 1 4) After the preheating is completed, the effluent of the coagulation sedimentation tank is passed into the ultraviolet-ozone-ultrasonic combined reactor ( figure 1 shown in ), start the ultrasonic array ( figure 1 Shown in 3), reflux treatment 2h;

[0060] Step 3, three-dimensional electrode electrolysis treatment: the effluent of the combined reactor is passed into the three-dimensional electrode electrolysis reactor ( figure 2 7), using polypyrrole-modified iridium oxide-co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com