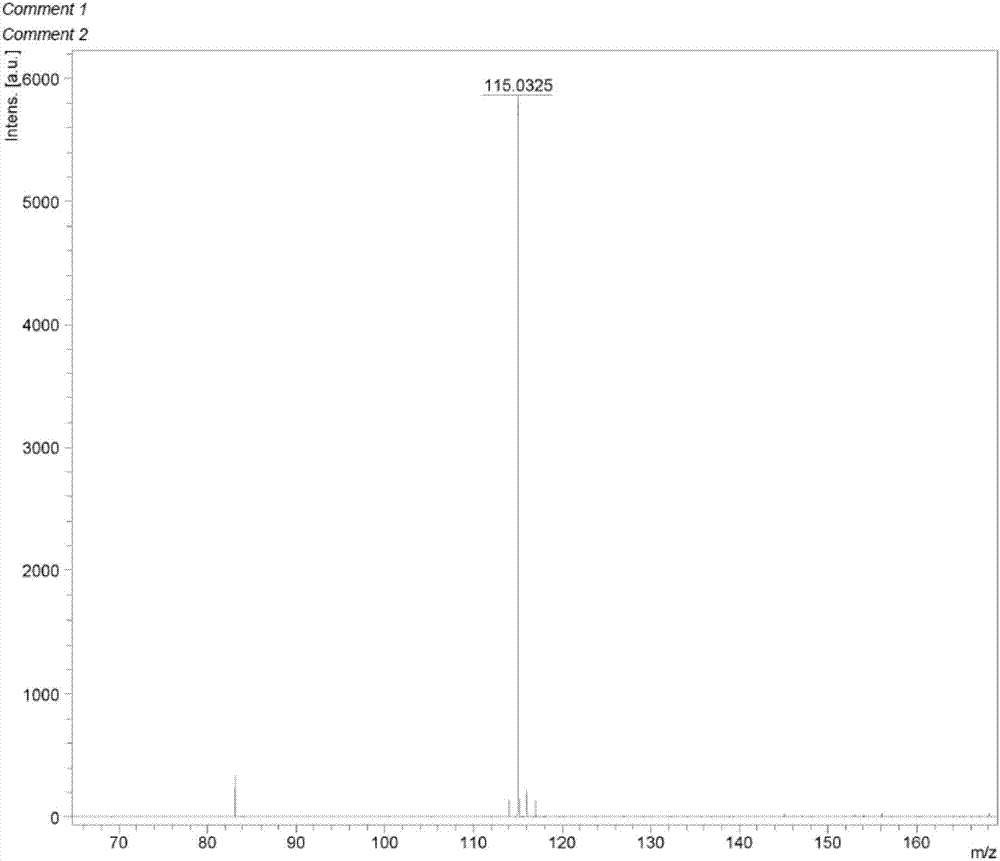

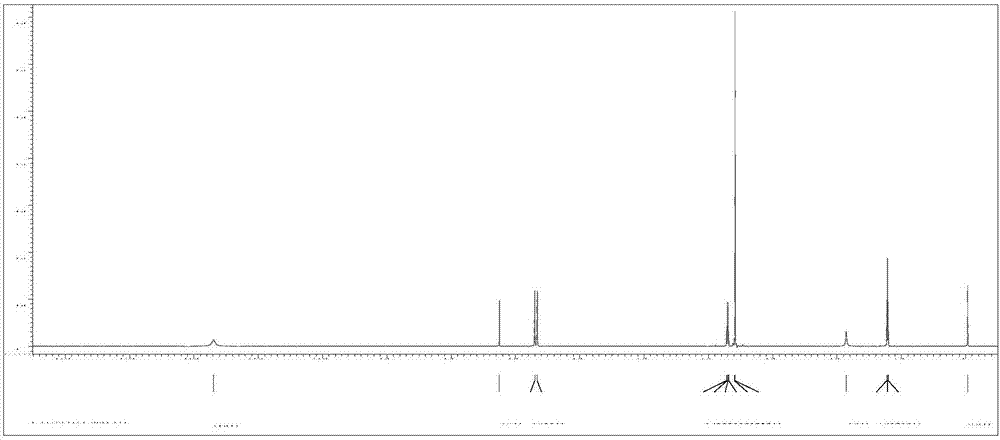

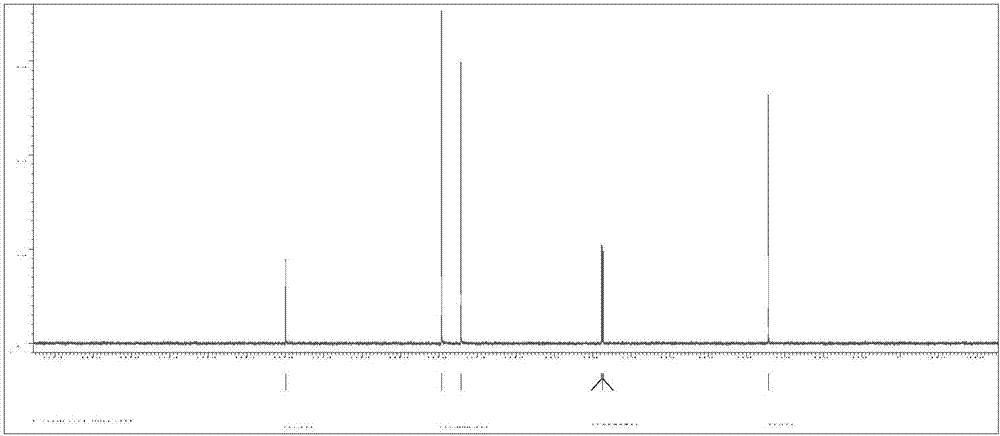

Methimazole preparation method

A technology of methimazole and methylamine, applied in the field of preparation of methimazole, can solve the problems of unfriendly environment, high production cost, not allowing benzene and the like, and achieve the effects of being environmentally friendly, easy to operate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Methanization: Add 3.00kg of chloroacetaldehyde dimethylacetal and 30kg of 33% methylamine methanol solution into the autoclave, close the autoclave valve, heat to 130-135℃, the maximum pressure is 1.2MPa, and then continue to decrease , Keep the temperature for 6 hours, lower the temperature to 25℃, and press to the neutralization tank. Stir and lower the temperature to below 10°C, add dropwise 3.26kg of 40% sodium methoxide methanol solution, and keep at 0-5°C for 2-3 hours. Filter, wash the filter cake with methanol, and transfer the filtrate to a distillation tank. Distill methanol at atmospheric pressure until it is no longer distilled out, change to vacuum distillation, turn on brine condensation to collect the intermediates, collect the 52-60℃ / 24mmHg fraction, obtain 2.51kg methylamino acetaldehyde dimethyl acetal, GC purity 94.6 %, the yield was 83.1%.

[0033] 2) Cycling:

[0034] Put 1.44kg sodium thiocyanate and 8.9kg purified water into the cyclization reac...

Embodiment 2

[0036] 1) Methanation:

[0037] Add 3.00kg of chloroacetaldehyde dimethylacetal and 30kg of 33% methylamine methanol solution into the autoclave, close the autoclave valve, heat to 120-125℃, the pressure is up to 1.0MPa, and then continue to decrease, keep warm for 10 hours, and cool down To 25℃, press to the neutralization tank. Stir and lower the temperature to below 10°C, add dropwise 3.26kg of 40% sodium methoxide methanol solution, and keep at 0-5°C for 2-3 hours. Filter, wash the filter cake with methanol, and transfer the filtrate to a distillation tank. Distill methanol at atmospheric pressure until it is no longer distilled out, change to vacuum distillation, turn on brine condensation to collect intermediates, collect 52-60°C / 24mmHg fractions, obtain 2.22kg methylaminoacetaldehyde dimethylacetal, and GC purity 93.7 %, the yield is 72.5%.

[0038] 2) Cycling:

[0039] Put 1.44kg sodium thiocyanate and 8.9kg purified water into the cyclization reactor, dissolve under stir...

Embodiment 3

[0041] 1) Methanation:

[0042] Add 3.00kg of chloroacetaldehyde dimethylacetal and 30kg of 33% methylamine methanol solution to the autoclave, close the autoclave valve, heat up to 145-150℃, and pressure up to 1.7MPa, then continue to decrease, keep the temperature for 10 hours, and cool down To 25℃, press to the neutralization tank. Stir and lower the temperature to below 10°C, add dropwise 3.26kg of 40% sodium methoxide methanol solution, and keep at 0-5°C for 2-3 hours. Filter, wash the filter cake with methanol, and transfer the filtrate to a distillation tank. Distill methanol at atmospheric pressure until it is no longer distilled out, change to vacuum distillation, turn on brine condensation to collect the intermediates, collect the 52-60℃ / 24mmHg fraction, and obtain 2.53kg methylaminoacetaldehyde dimethylacetal with a purity of 93.5 by GC %, the yield was 82.7%.

[0043] 2) Cycling:

[0044] Put 1.44kg sodium thiocyanate and 8.9kg purified water into the cyclization reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com