Fluorine-doped carbon-coated manganese oxide synthetic method and application thereof

A synthesis method and manganese oxide technology, which is applied in the field of lithium ion capacitors, can solve the problems that the electrochemical performance cannot be better satisfied, and achieve the effects of good control, simple operation, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The synthesis method of fluorine-doped carbon-coated manganese oxide is characterized in that: the method uses Nafion solution and manganese acetate solution as main raw materials, and comprises the following steps:

[0022] 1) Slowly add manganese acetate solution dropwise to the Nafion solution and stir, adjust the pH to 6.5~7.5 with NaOH isopropanol solution, and let the resulting mixture stand for a full reaction;

[0023] 2), drying the reaction solution to obtain a solid product, and roasting the obtained solid product at high temperature;

[0024] 3), naturally cool the solid product after high-temperature roasting to room temperature to obtain fluorine-doped carbon-coated manganese oxide;

[0025] The mass percentage of manganese oxide in the final fluorine-doped carbon-coated manganese oxide is 30-50%.

[0026] In the step 1), the stirring time is preferably controlled at more than 1 hour; during the standing reaction of the obtained mixed solution, the pH val...

Embodiment 1

[0030] 1) Take an appropriate amount of Nafion solution, slowly add manganese acetate solution dropwise into the Nafion solution and stir, stir for 1 hour, adjust the pH value to 6.5 with NaOH isopropanol solution, and let the resulting mixture stand for 8 hours to fully react;

[0031] 2) Dry the reaction liquid to obtain a solid product, and roast the obtained solid product at a high temperature, the drying temperature is controlled at 50°C, the drying time is controlled at 8h, and the high-temperature roasting is heated to 800°C at a heating rate of 5°C / min, and roasted for 2.5h;

[0032] 3) Insulate the solid product calcined at high temperature for 1 hour, and then naturally cool to room temperature to obtain fluorine-doped carbon-coated manganese oxide;

[0033] The consumption of Nafion and manganese acetate must ensure that the mass percentage of manganese oxide in the final product is at 30%.

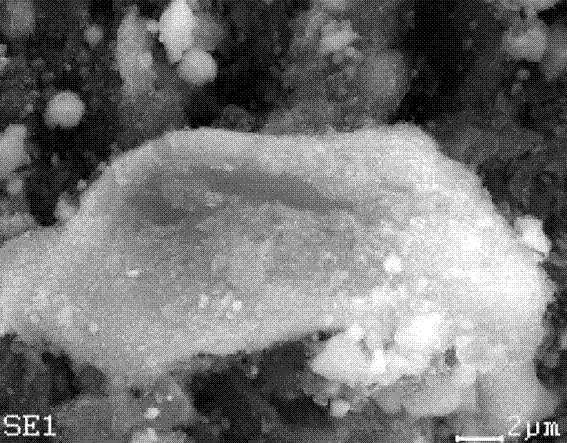

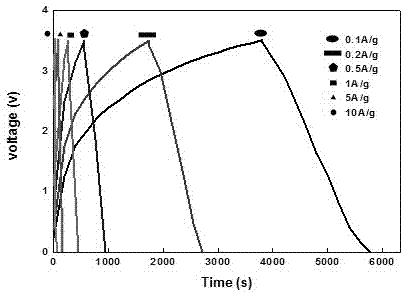

[0034] According to visual inspection, the fluorine-doped carbon-coated ma...

Embodiment 2

[0036] 1) Take an appropriate amount of Nafion solution, slowly add manganese acetate solution dropwise into the Nafion solution and stir, stir for 1.5 hours, adjust the pH value to 6.8 with NaOH isopropanol solution, and let the resulting mixture stand for 9 hours to fully react;

[0037] 2) Dry the reaction solution to obtain a solid product, and roast the obtained solid product at a high temperature. The drying temperature is controlled at 60°C, and the drying time is controlled at 10h. The high-temperature roasting adopts a heating rate of 5°C / min to raise the temperature to 850°C, and roast for 3h;

[0038] 3) Insulate the solid product after high-temperature roasting for 1.5 hours, and then naturally cool to room temperature to obtain fluorine-doped carbon-coated manganese oxide;

[0039] The consumption of Nafion and manganese acetate must ensure that the mass percentage of manganese oxide in the final product is at 35%.

[0040] According to visual inspection, the fluo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com