Method for transferring graphene by using rosin resin as well as preparation method and application of transparent conductive graphene film

A transparent conductive film, rosin resin technology, applied in graphene, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc., can solve problems such as hindering application, graphene damage, and difficulty in dissolving, and achieve high cleanliness. Transfer, improve Support strength, good for large area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

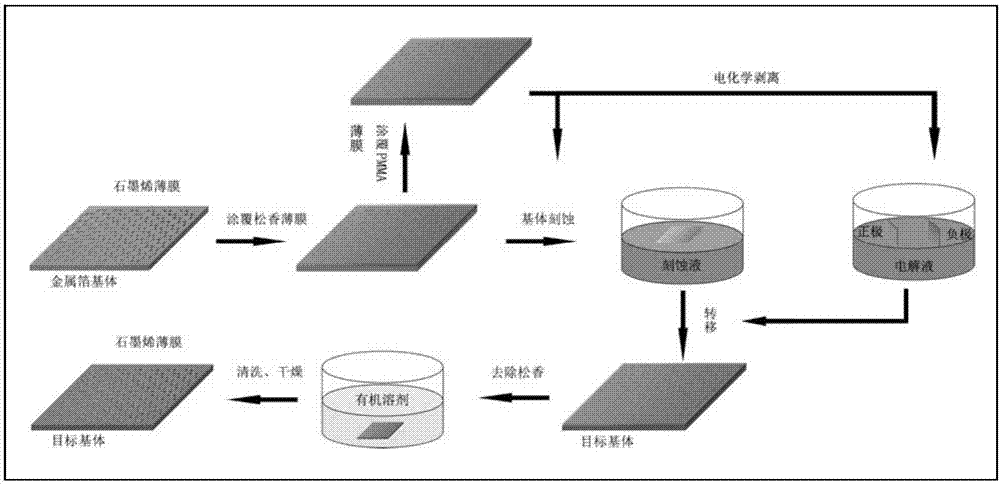

[0039] like figure 1 Shown, the method for rosin resin transfer graphene comprises the steps:

[0040] (1) First dissolve the natural rosin resin in absolute ethanol at a concentration of 1:1 (mass ratio), then spin-coat a layer of rosin with a thickness of 50 μm on the surface of single-layer graphene grown on Cu foil, and solidify at room temperature 2h, the rosin / graphene / metal foil composite was obtained.

[0041] (2) Etch the obtained rosin / graphene / Cu foil composite to remove the Cu foil by etching, move it to deionized water for repeated cleaning, and obtain the rosin / graphene composite.

[0042] (3) Transfer the rosin / graphene complex to the surface with SiO 2 Thin layer of Si sheet surface, heated at 40°C for 120min to remove graphene and SiO 2 Moisture between / Si makes them more tightly combined.

[0043] (4) Rosin / graphene / SiO 2 The / Si complex was sequentially washed with acetone and banana water to remove the rosin resin, and finally washed with deionized wa...

Embodiment 2

[0045] The difference from Example 1 is that in this example, hydrogenated rosin is dissolved in ethyl lactate at a concentration of 1:5 (mass ratio), and coated on 5-layer graphene grown on Ni, and the thickness of rosin is 30nm , cured at 100°C for 40 minutes; the target substrate used was GaN, and placed at room temperature for 5 hours to remove the moisture between the graphene film and the GaN substrate, so that the combination of rosin / graphene and the GaN substrate was tighter, and the obtained graphene surface The resistance is 125ohm / sq.

Embodiment 3

[0047] The difference from Example 1 is that in this example, the disproportionated rosin is dissolved in ethyl acetate at a concentration of 1:1 (mass ratio), and coated on the single-layer graphene grown on Cu, and the thickness of the rosin is 150 μm , cured at 180°C for 90min; the target substrate used was sapphire (Al 2 o 3 ), placed at room temperature for 1h to remove the moisture between the graphene film and the sapphire substrate, so that the combination of rosin / graphene and the sapphire substrate is more tightly, and the resulting graphene surface resistance is 550ohm / sq.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistance | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com