A kind of weather-resistant solar battery back plate and preparation method thereof

A solar cell, weather resistance technology, applied in the direction of climate sustainability, circuits, electrical components, etc., can solve the problems of high price, poor weather resistance of the backplane, and inability to meet the requirements of high-end products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

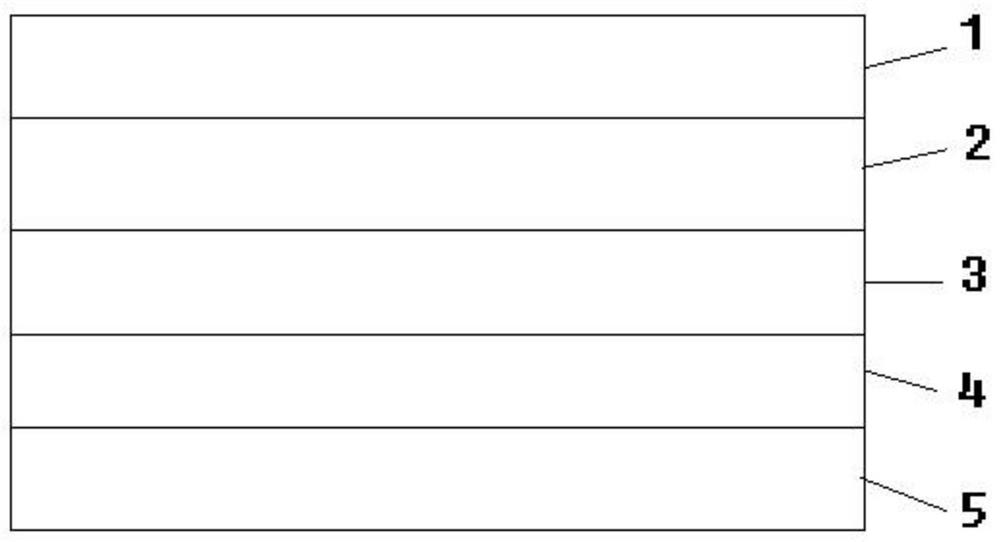

[0028] Correspondingly, the present invention also provides a method for preparing a weather-resistant solar battery back sheet, comprising the following steps: performing esterification and polycondensation reaction of terephthalic acid and hexafluoropentanediol to obtain a first fluoropolymer, and preparing the obtained The above-mentioned fluoropolymer is melt-extruded at 220-250°C, cooled and solidified, and rolled to obtain the first weather-resistant film; terephthalic acid and hexafluoropentanediol are reacted through esterification and polycondensation to obtain the second fluoropolymer , the fluoropolymer is melt-extruded at 220-250°C, cooled and solidified, and rolled to obtain a second weather-resistant film; the first adhesive, the second adhesive and the first composition are independently prepared in the Melt extrusion at 220-250°C, cooling and solidification, and roll calendering to obtain the first adhesive film, the second adhesive film and the core film, the f...

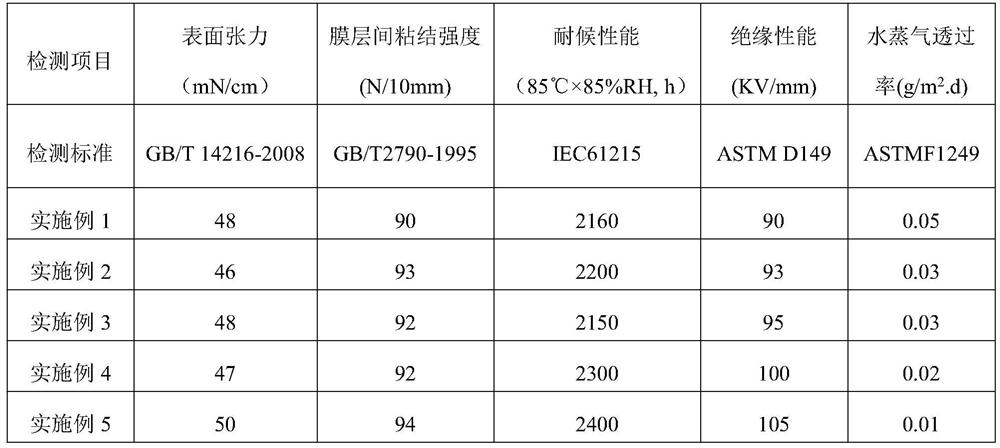

Embodiment 1

[0039] The preparation method of the fluorine-containing polymer comprises the following steps: adding 100g of purified terephthalic acid and 140g of hexafluoropentanediol into a polymerization reactor, sealing it, and carrying out the esterification reaction at 270° C. for 2 hours under reflux, and after the esterification reaction Add the catalyst antimony trioxide, lower the pressure to below 180Pa, carry out the polycondensation reaction at 250°C for 4 hours, then coagulate the product in deionized water, and dry it in a vacuum oven at 60°C for 12 hours to obtain fluorine-containing polymer things.

[0040] The first composition forming the core layer consists of the following components by weight: 70 parts of ethylene-butadiene-styrene triblock copolymer, 20 parts of silicon dioxide, 3 parts of coupling agent KH570, 0.5 part of antioxidant 1010.

[0041] The preparation method of the weather-resistant solar battery back sheet is as follows:

[0042] Preparation of base ...

Embodiment 2

[0045] The preparation method of the fluorine-containing polymer comprises the following steps: adding 100g of purified terephthalic acid and 130g of hexafluoropentanediol into a polymerization reactor, sealing it, and carrying out an esterification reaction at 280°C for 2.5 hours under reflux, and after the esterification reaction Add catalyst antimony acetate, lower the pressure to below 180Pa, carry out polycondensation reaction at 260°C for 5 hours, then coagulate the product in deionized water, and dry it in a vacuum oven at 65°C for 15 hours to obtain a fluoropolymer.

[0046] The first composition forming the core layer consists of the following components by weight: 72 parts of ethylene-butadiene-styrene triblock copolymer, 23 parts of silicon dioxide, 4 parts of coupling agent KH550, 0.7 parts of antioxidant 300.

[0047] The preparation method of the weather-resistant solar battery back sheet is as follows:

[0048] Preparation of base film: Melt and extrude the flu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| electrical insulator | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com