Temperature sensitive-type hydrogel nano drug delivery system

A temperature-sensitive, hydrogel nano-technology, applied in the field of medicine, to achieve the effect of improving the therapeutic effect, improving the curative effect, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 100 parts of N-isopropylacrylamide (NIPAM), 35 parts of acrylic acid (AA), 5 parts of N,N-methylenebisacrylamide, 1 part of sodium dodecylsulfonate, ammonium persulfate / sulfurous acid Mix 10 parts of sodium hydrogen, 60 parts of water, 10 parts of receptor tyrosine kinase inhibitor, 10 parts of anti-angiogenic agent, and 10 parts of propanol, and remove the air in the reaction system at 0-50°C for 0.1-2 hours , under anaerobic conditions, heating the reaction system to 35-100°C for 4-20 hours to obtain the product;

[0045] 3) Obtain the centrifuged product by washing and centrifuging for many times;

[0046] 4) Vacuum drying the product obtained in step 3) at 0-50° C. to obtain a hydrogel nano drug delivery system.

[0047] Detection:

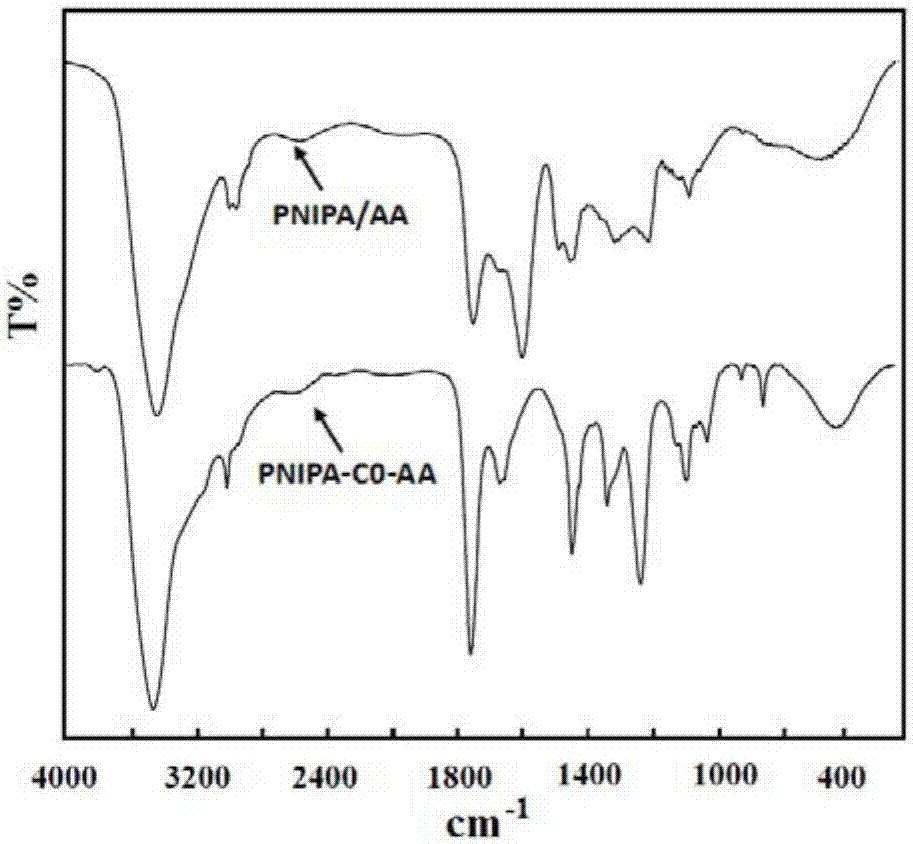

[0048] The polymerization reaction of temperature-sensitive nanohydrogels was verified by infrared spectrophotometer. From the infrared spectrum analysis chart (see figure 1 ), it can be seen that the curve NIPAM / AA is a mixture of ...

Embodiment 2

[0053] 100 parts of N-isopropylacrylamide (NIPAM), acrylic acid (AA) (the molar ratios of N-isopropylacrylamide and acrylic acid are 98:2 / 95:5 / 92:8 / 90:10), 5 parts of N,N-methylenebisacrylamide, 1 part of sodium dodecylsulfonate, 0.1 part of potassium persulfate, 50 parts of water, 10 parts of PI3K / mTOR / AKT inhibitor, 10 parts of isopropanol and mix well , remove the air in the reaction system at 0-50°C for 0.1-2 hours, and heat the reaction system to 35-100°C for 4-20 hours under anaerobic conditions to obtain the product;

[0054] 3) Obtain the centrifuged product by washing and centrifuging for many times;

[0055] 4) Vacuum drying the product obtained in step 3) at 0-50° C. to obtain a hydrogel nano drug delivery system.

[0056] Detection:

[0057] The particle diameters of the nano-drug delivery system obtained in this example were measured by a laser particle size analyzer to be 100-300 nm.

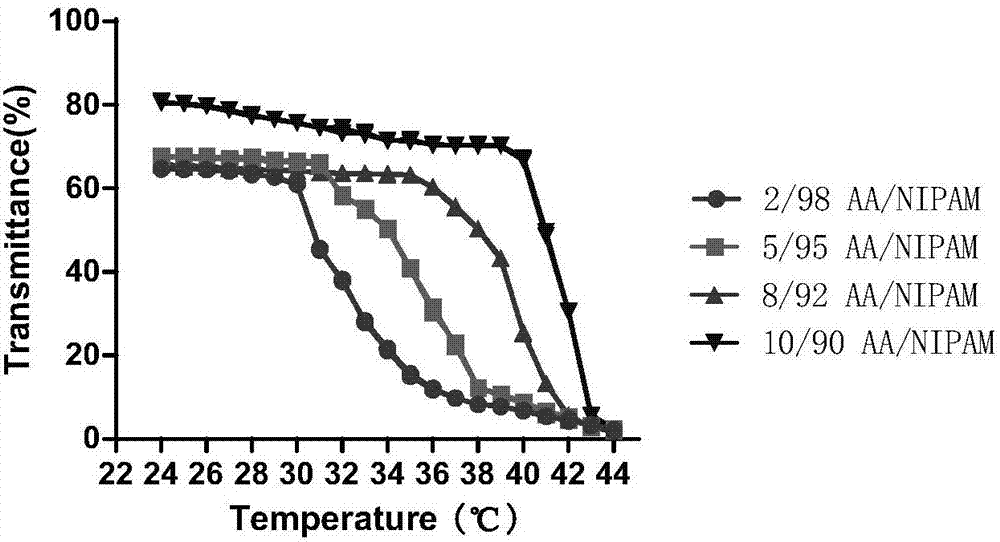

[0058] Optimization of temperature-sensitive nano-hydrogels: The light tran...

Embodiment 3

[0060] 100 parts of N-isopropylacrylamide, 15 parts of acrylic acid, 20 parts of N,N-methylenebisacrylamide, 3 parts of sodium dodecylsulfonate, 15 parts of ammonium persulfate initiator, 50 parts of water, After mixing 5 parts of monoclonal antibody anticancer drugs and 100 parts of glucose, the air in the liquid was removed at 25°C for 0.1 hour, and the reaction system was heated to 60°C for 8 hours under anaerobic conditions to obtain the product. The unwrapped drug or anticancer drug inclusions and auxiliary agents and unpolymerized small molecule raw materials were removed by dialysis separation, and the hydrogel nano drug delivery system was obtained by vacuum drying at 25°C.

[0061] Detection:

[0062] The particle diameters of the nano-drug delivery system obtained in this example were measured by a laser particle size analyzer to be 300-500 nm.

[0063]Drug loading test: use the monoclonal antibody kit to test the concentration of the monoclonal antibody in the dial...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com