Construction method of enzyme-reponsive multifunctional nano-coating

A nano-coating and construction method technology, applied in coatings, pharmaceutical formulations, surgery, etc., can solve the problems of surface modification of nano-coating cardiovascular materials, loss of biological activity, and difficulty in maintaining long-term functions of biological coatings. , to achieve the effect that the construction process and fixing method are simple and easy to operate, realize functional modification, and have a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

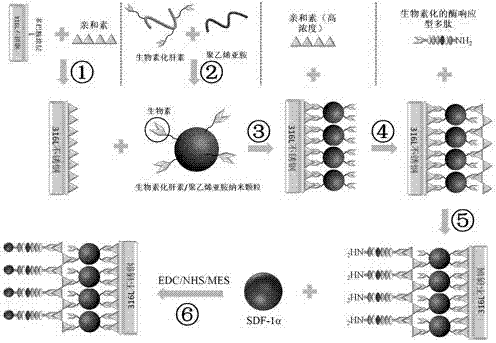

[0032] see figure 1 , the first specific embodiment of the present invention is a method for constructing an enzyme-responsive nano-coating, the steps of which are:

[0033] A) After the surface of 316L stainless steel was polished and cleaned, it was immersed in a dopamine solution with a concentration of 2 mg / ml to react for 12 hours. After ultrasonic cleaning with double distilled water, the above steps were repeated twice to obtain three layers of polydopamine coating surface, dry at 37°C;

[0034] B) Soak the sample deposited with polydopamine coating in step A) in 0.1 mg / ml avidin solution, let it stand for reaction at 37°C for 8 hours, then wash the sample with double distilled water, and save it for later use;

[0035]C) The biotinylated heparin sodium solution with a concentration of 10 mg / ml and the polyethyleneimine solution with a concentration of 1 mg / ml were blended in equal volumes, and ultrasonically treated for 5 minutes at room temperature to obtain a nanopa...

Embodiment 2

[0043] A method for constructing an enzyme-responsive nano-coating, the steps of which are:

[0044] A) After the surface of 316L stainless steel was polished and cleaned, it was immersed in a dopamine solution with a concentration of 2 mg / ml to react for 12 hours. After ultrasonic cleaning with double distilled water, the above steps were repeated twice to obtain three layers of polydopamine coating surface, dry at 37°C;

[0045] B) Soak the sample deposited with polydopamine coating in step A) in 0.5 mg / ml avidin solution, let it stand for reaction at 37°C for 8-24 hours, then wash the sample with double distilled water, and store it until use;

[0046] C) The biotinylated heparin sodium solution with a concentration of 20 mg / ml and the polyethyleneimine solution with a concentration of 2 mg / ml were blended in equal volumes, and ultrasonically treated for 5 minutes at room temperature to obtain a nanoparticle suspension. Submerge the sample obtained in step B into the nano...

Embodiment 3

[0054] A method for constructing an enzyme-responsive nano-coating, the steps of which are:

[0055] A) After the surface of 316L stainless steel was polished and cleaned, it was immersed in a dopamine solution with a concentration of 2 mg / ml to react for 12 hours. After ultrasonic cleaning with double distilled water, the above steps were repeated twice to obtain three layers of polydopamine coating surface, dry at 37°C;

[0056] B) Soak the sample deposited with polydopamine coating in step A) in 0.3 mg / ml avidin solution, let it stand for reaction at 37°C for 12 hours, then wash the sample with double distilled water, and save it for later use;

[0057] C) The biotinylated heparin sodium solution with a concentration of 15 mg / ml and the polyethyleneimine solution with a concentration of 1.5 mg / ml were blended in equal volumes, and ultrasonically treated for 5 minutes at room temperature to obtain a nanoparticle suspension. Submerge the sample obtained in step B into the na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com