A pig farm sewage treatment filler, multi-coupling process and system

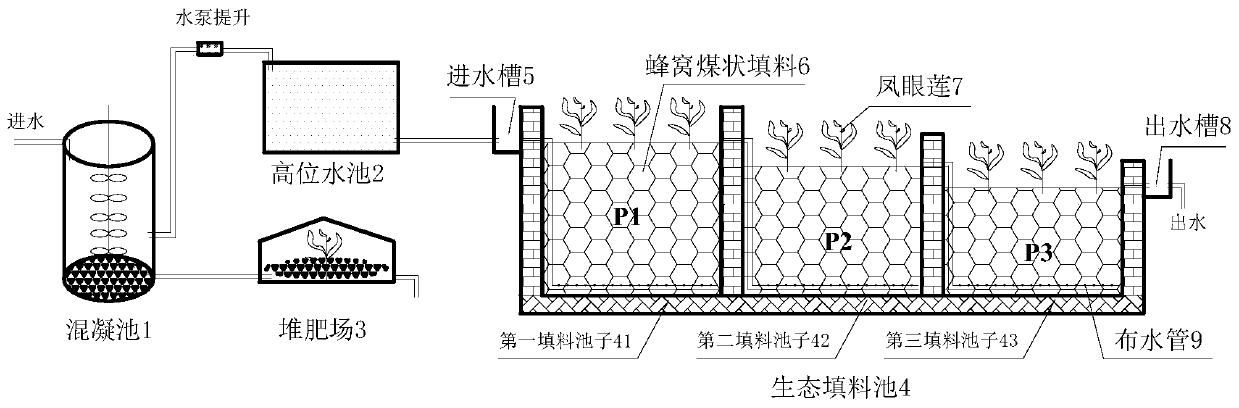

A coupling system and sewage treatment technology, which is applied in the field of livestock and poultry breeding pollution control, can solve the problems of surrounding residents' health hazards, ineffective recycling of carbon sources, high investment and operating costs, and achieve significant economic and environmental benefits. The effect of resource utilization and reduction of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Zeolite powder with ammonia absorption value (CEC)=150cmol / kg, 80-mesh gypsum powder, cement, industrial coarse salt with a feed particle size of 2mm, and biochar with a particle size of 1mm according to 50%, 30%, 10%, 5 %, 5% mass ratio, mix and stir evenly, according to the mass ratio of 50% ~ 70%, spray clean water into the uniformly mixed material and stir evenly, use a briquette machine to make the material after spraying clean water into a diameter of 100mm, a height of 75mm, There are 12 briquette-like fillers 6 with a diameter of 14 mm evenly distributed, and the briquette-like filler 6 is air-dried naturally.

Embodiment 2

[0033] Zeolite powder with ammonia absorption value (CEC)=160cmol / kg, 85 mesh gypsum powder, cement, industrial crude salt with a feed particle size of 2.5mm, and biochar with a particle size of 1.5mm according to 56%, 25%, 7% , 4%, 8% mass ratio and mix and stir evenly, according to the mass ratio of 50% ~ 70%, spray clean water into the well-mixed material and stir evenly, use a briquette machine to make the material after spraying clean water into a diameter of 100mm, high 75mm, with 12 briquette-like fillers 6 with a diameter of 14mm evenly distributed, and the briquette-like filler 6 is naturally air-dried.

Embodiment 3

[0035]The zeolite powder with ammonia absorption value (CEC)=165cmol / kg, 90 mesh gypsum powder, cement, industrial crude salt with a feed particle size of 3mm, and biochar with a particle size of 1.2mm according to 60%, 20%, 5%, 6% and 9% mass ratio are mixed and stirred evenly, according to the mass ratio of 50% to 70%, water is sprayed into the uniformly mixed material and stirred evenly, and the material after spraying water is made into a diameter of 100mm and a height of 75mm by a briquette machine 12 briquette-like fillers 6 with a diameter of 14 mm are evenly distributed, and the briquette-like fillers 6 are naturally air-dried.

[0036] The multi-component coupling process for treating pig farm sewage of the present invention, in step S2:

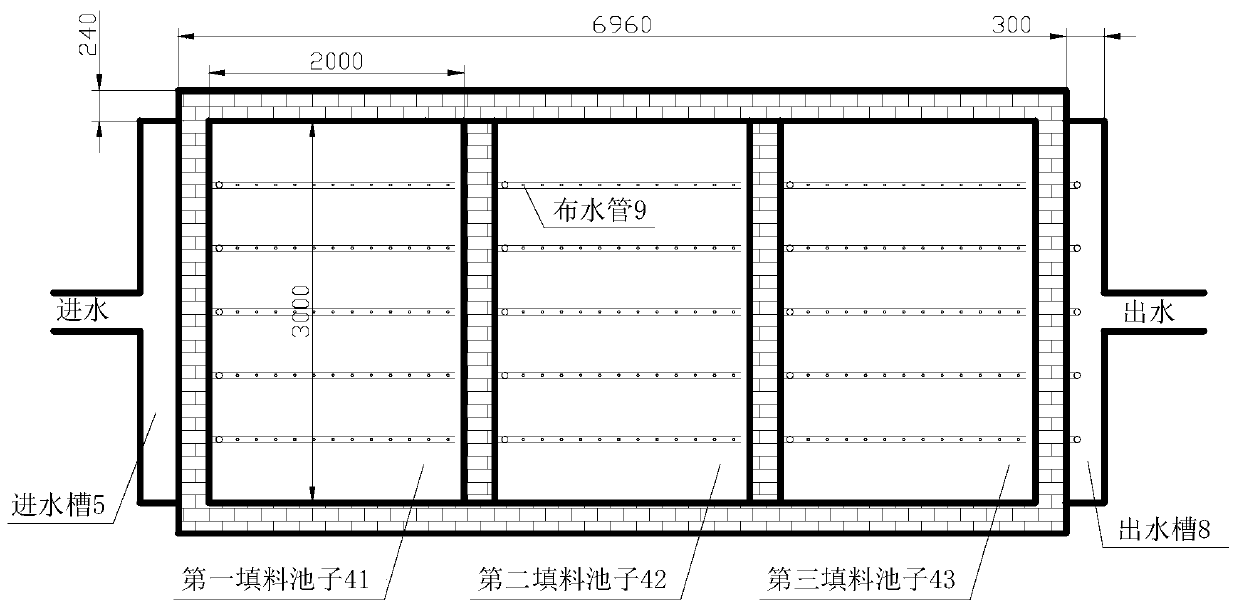

[0037] Collect 7 plants of water hyacinth with a height of 20-40cm from the wild, according to 10-20 plants / m 2 The inoculation density of water hyacinth 7 is added to the surface water body of the ecological filler pool 4 .

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com