A kind of antibacterial alginate fiber, its preparation method and application of dressing

An antibacterial alginate and alginate technology, applied in fiber treatment, natural fiber, biochemical fiber treatment and other directions, can solve the problems of adverse drug resistance, adverse side effects, high honey addition, and high safety risks, and achieve antibacterial aging. Long-lasting, low-dissolution, and safety-risk-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

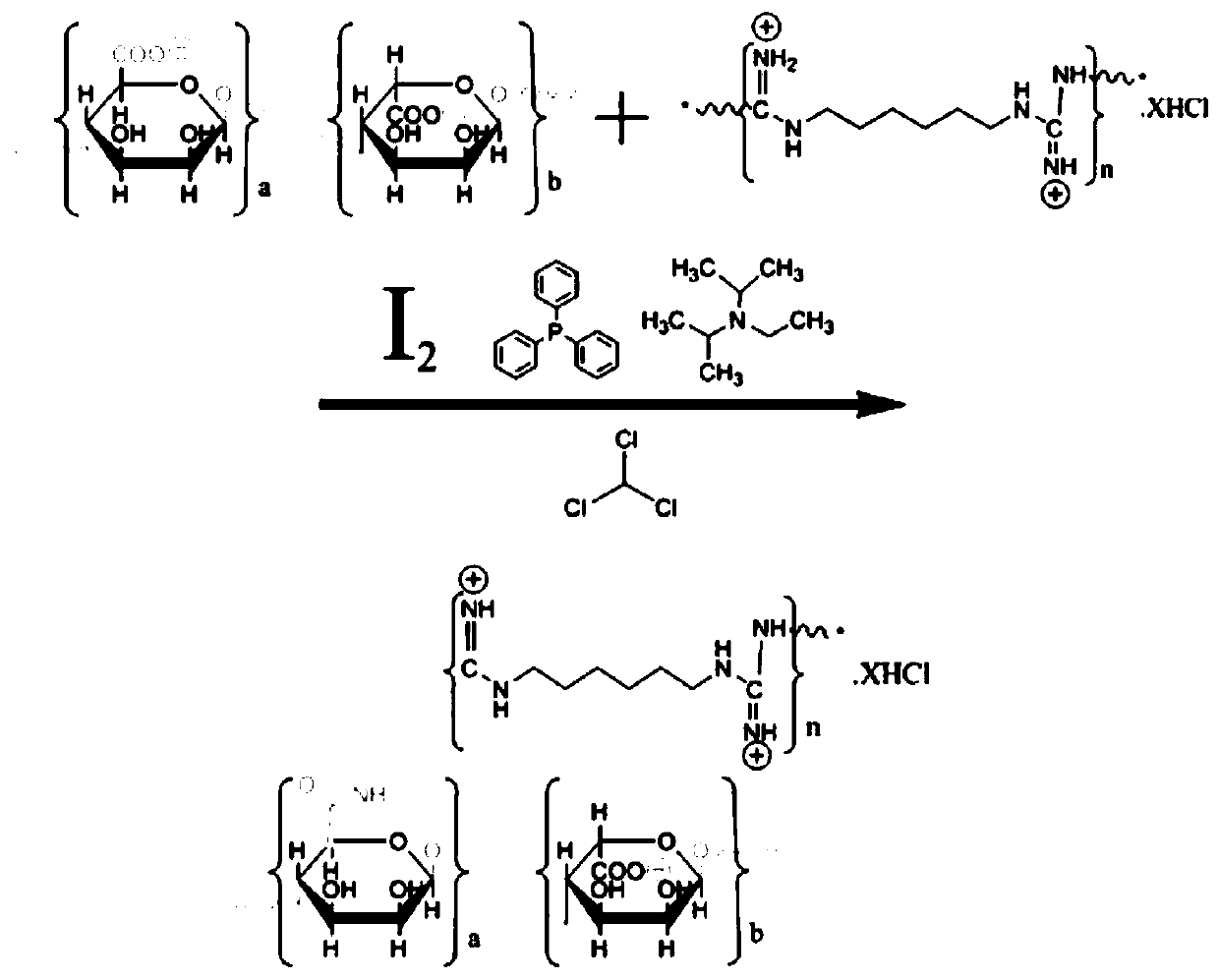

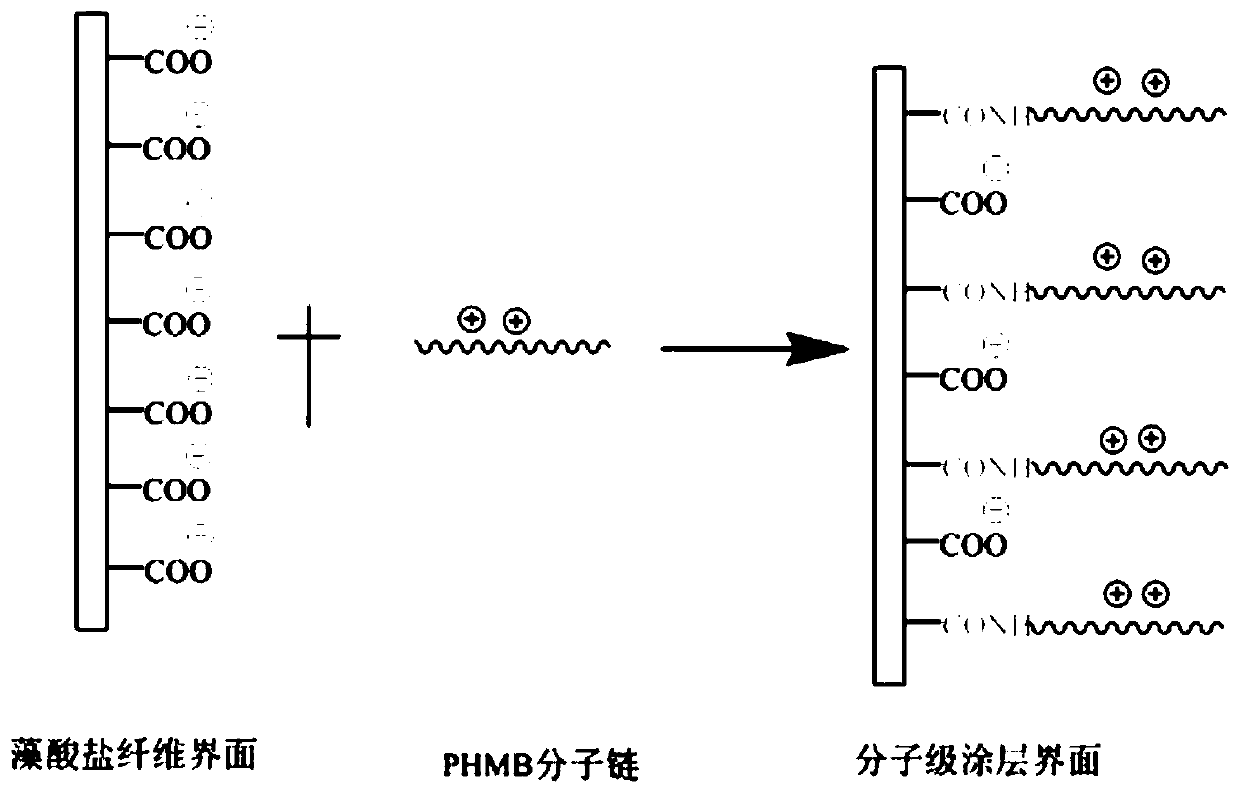

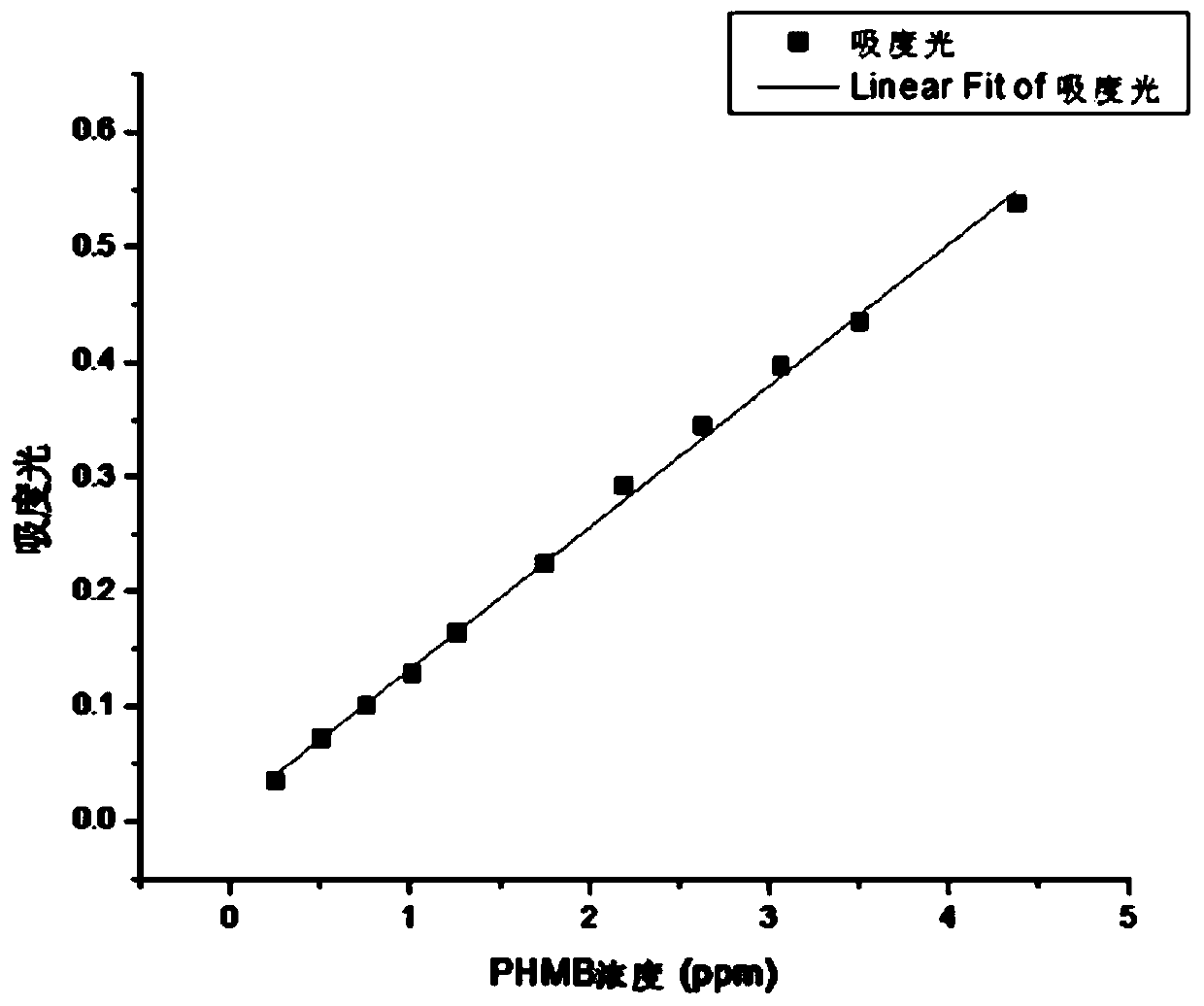

[0048] A preparation method of antibacterial alginate fiber. Take 1000g of short-fiber alginate of 3-5cm, put it into 5000g of 0.54% hydrochloric acid and 9.5% ethanol aqueous solution at 20°C, stir and activate for 3.0 hours, centrifuge to separate the liquid, and then 2000g of absolute ethanol soaks the fiber for 10-15 minutes, centrifuges the ethanol to obtain an activated alginate fiber; 110g of N,N-diisopropylethylamine is added to 5500g of chloroform solution under stirring at 70r / min (triphenyl Base phosphine: 0.235%, iodine: 0.228%), and start the stopwatch timing, after stirring for 1 to 2 minutes, put the activated alginate fiber into the solution, stir for 3 to 5 minutes, activate at 35°C for 30 minutes, and then Take out the fibers, squeeze the separation solution to obtain secondary activated fibers; then mix and stir 4000 g of PHMB ethanol solution with a mass concentration of 0.028% and the secondary activated fibers at 25°C for 40 minutes, press the separation s...

Embodiment 2

[0051] A preparation method of antibacterial alginate fiber. Take 1000g of short-fiber alginate of 3-5cm, put it into 5000g of 0.54% hydrochloric acid and 9.5% ethanol aqueous solution at 20°C, stir and activate for 3.0 hours, centrifuge to separate the liquid, and then 2000g of absolute ethanol soaks the fiber for 10-15 minutes, centrifuges the ethanol to obtain an activated alginate fiber; 110g of N,N-diisopropylethylamine is added to 5500g of chloroform solution under stirring at 70r / min (triphenyl Base phosphine: 0.235%, iodine: 0.228%), and start the stopwatch timing, after stirring for 1 to 2 minutes, put the activated alginate fiber into the solution, stir for 3 to 5 minutes, activate at 35°C for 30 minutes, and then Take out the fibers, squeeze the separation solution to obtain secondary activated fibers; then mix and stir 4000 g of PHMB ethanol solution with a mass concentration of 0.038% and the secondary activated fibers at 25°C for 40 minutes, press the separation s...

Embodiment 3

[0054] A kind of preparation method of antibacterial alginate fiber, take 1000g of filament fiber alginate, put into 5000g containing 0.54% hydrochloric acid, 9.5% ethanol aqueous solution at 20 ℃, stir and activate for 3.0 hours, centrifuge to separate liquid, then 2000g Soak the fiber with water and ethanol for 10-15 minutes, and centrifuge the ethanol to obtain an activated alginate fiber; add 110g of N,N-diisopropylethylamine to 5500g of chloroform solution under stirring at 70r / min (triphenylphosphine: 0.235%, iodine: 0.228%), and start the stopwatch timing, after stirring for 1 to 2 minutes, put an activated alginate fiber into the solution, stir for 3 to 5 minutes, activate at 35°C for 30 minutes, and then take out the fiber, Squeeze the separation solution to obtain secondary activated fibers; then mix 4000g of PHMB ethanol solution with a mass concentration of 0.052% with the secondary activation fibers at 25°C for 40 minutes, and put the fibers into the previous chlor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com