Tungsten trioxide composite photoelectrode as well as preparation method and application of tungsten trioxide composite photoelectrode in decomposition of water through photoelectrocatalysis

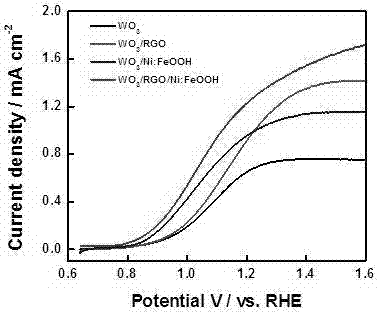

A technology of tungsten trioxide and composite light, applied in electrodes, electrolysis process, electrolysis components, etc., to achieve the effect of improving transfer efficiency, promoting oxygen evolution reaction, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

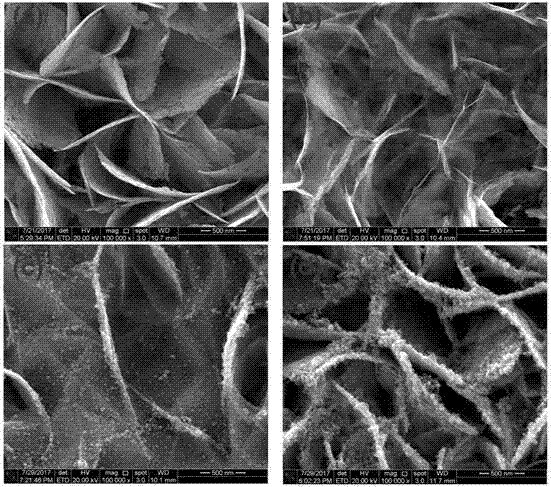

[0032] A preparation method of a tungsten trioxide composite photoelectrode, comprising the following steps:

[0033] (1) Add 0.625g tungstic acid and 0.25g polyvinyl alcohol into 8.5mL hydrogen peroxide solution, stir overnight to form a uniform solution and obtain a seed layer solution; pass the FTO conductive glass through acetone, absolute ethanol and dehydrated After ultrasonication of the ionized water for 15 minutes, dry it with nitrogen gas; then place the FTO conductive glass on the rotating disk of the spin coater, pipette 150 μL of the seed layer solution and drop-coat it on the conductive glass, and the coating area is fixed as 1.5cm 2 , the rotation speed is 3000 rpm, and it is maintained for 30 seconds. This is a spin-coating cycle. The number of spin-coating cycles is 5 times. The FTO conductive glass is coated with a colorless film; then the coated FTO conductive glass is placed On a temperature-controlled titanium substrate heating platform, raise the tempera...

Embodiment 2

[0038] A preparation method of a tungsten trioxide composite photoelectrode, comprising the following steps:

[0039] (1) Add 0.595g tungstic acid and 0.17g polyvinyl alcohol into 8.5mL hydrogen peroxide solution, stir overnight to form a uniform solution and obtain a seed layer solution; pass the FTO conductive glass through acetone, absolute ethanol and dehydrated After ultrasonication of the ionized water for 15 minutes, dry it with nitrogen gas; then place the FTO conductive glass on the rotating disk of the spin coater, pipette 120 μL of the seed layer solution and drop-coat it on the conductive glass with a fixed coating area of 1.5cm 2 , the rotating speed is 3500 rpm, and it is maintained for 20 seconds. This is a spin-coating cycle. The number of spin-coating cycles is 20 times in total. The FTO conductive glass is coated with a colorless film; then the coated FTO conductive glass is placed On the temperature-controlled titanium substrate heating platform, the temper...

Embodiment 3

[0044] A preparation method of a tungsten trioxide composite photoelectrode, comprising the following steps:

[0045] (1) Add 0.68g tungstic acid and 0.34g polyvinyl alcohol into 8.5mL hydrogen peroxide solution, stir overnight to form a uniform solution and obtain a seed layer solution; pass the FTO conductive glass through acetone, absolute ethanol and dehydrated After the ionized water was ultrasonicated for 15 minutes, it was blown dry with nitrogen; then the FTO conductive glass was placed on the rotating disk of the spin coater, and 180 μL of the seed layer solution was pipetted with a pipette gun and drip-coated on the conductive glass, and the coating area was fixed as 1.5cm 2 , the rotating speed is 2500 rpm, and it is maintained for 40 seconds. This is a spin-coating cycle. The number of spin-coating cycles is 10 times in total. The FTO conductive glass is coated with a colorless film; then the coated FTO conductive glass is placed On the temperature-controlled tita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com