Compound semiconductor metal contact electrode

A metal contact and semiconductor technology, applied in the direction of semiconductor devices, circuits, electrical components, etc., can solve the problems of fuzzy boundaries of contact resistance electrodes, high manufacturing costs, device failure, etc., to achieve lateral uniformity and stability improvement, production Reduced manufacturing cost and beneficial effect on device size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

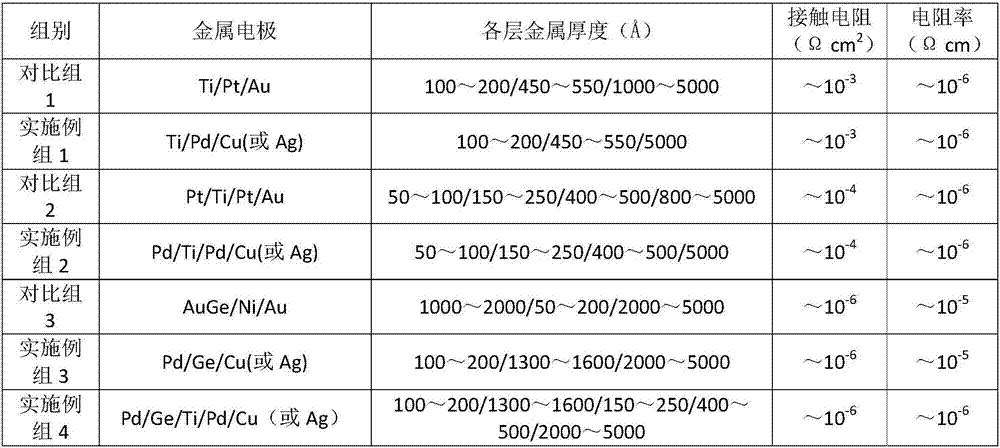

[0022] Prepare metal contact electrodes with the above four structures, that is, prepare Ti / Pd / Cu (or Ag), Pd / Ti / Pd / Cu (or Ag) and alloy metal electrodes Pd / Ge / Cu (or Ag), Pd / Metal contact electrodes with four structures of Ge / Ti / Pd / Cu (or Ag) are used as an embodiment group; metal contact electrodes are prepared with three structures in the prior art, namely preparing Ti / Pt / Au, Pt / Ti / Pt / Au and AuGe / Ni / Au metal contact electrodes with three structures were used as comparison groups.

[0023] By doping concentration ~ 10 19 / cm 3 Thickness is On the n-GaAs test sheet, after photolithography, electron beam evaporation and organic solvent stripping of various metal electrodes to form patterns, adopt the method of "transmission line measurement" to obtain various non-alloy contact electrodes and alloy heat treatment process (He, 250-400°C, 1-3 minutes), the metal contact resistance of the alloy contact electrode was measured, and the intrinsic resistance was measured by comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com