A three-dimensional micro-nano structure electrochemical induction processing method

A technology of micro-nano structure and processing method, applied in the field of three-dimensional micro-nano structure electrochemical induction processing, can solve the problems of expensive processing equipment, expensive energy beam equipment, low processing efficiency, etc., achieve simple and easy processing technology, and reduce processing complexity Degree, the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

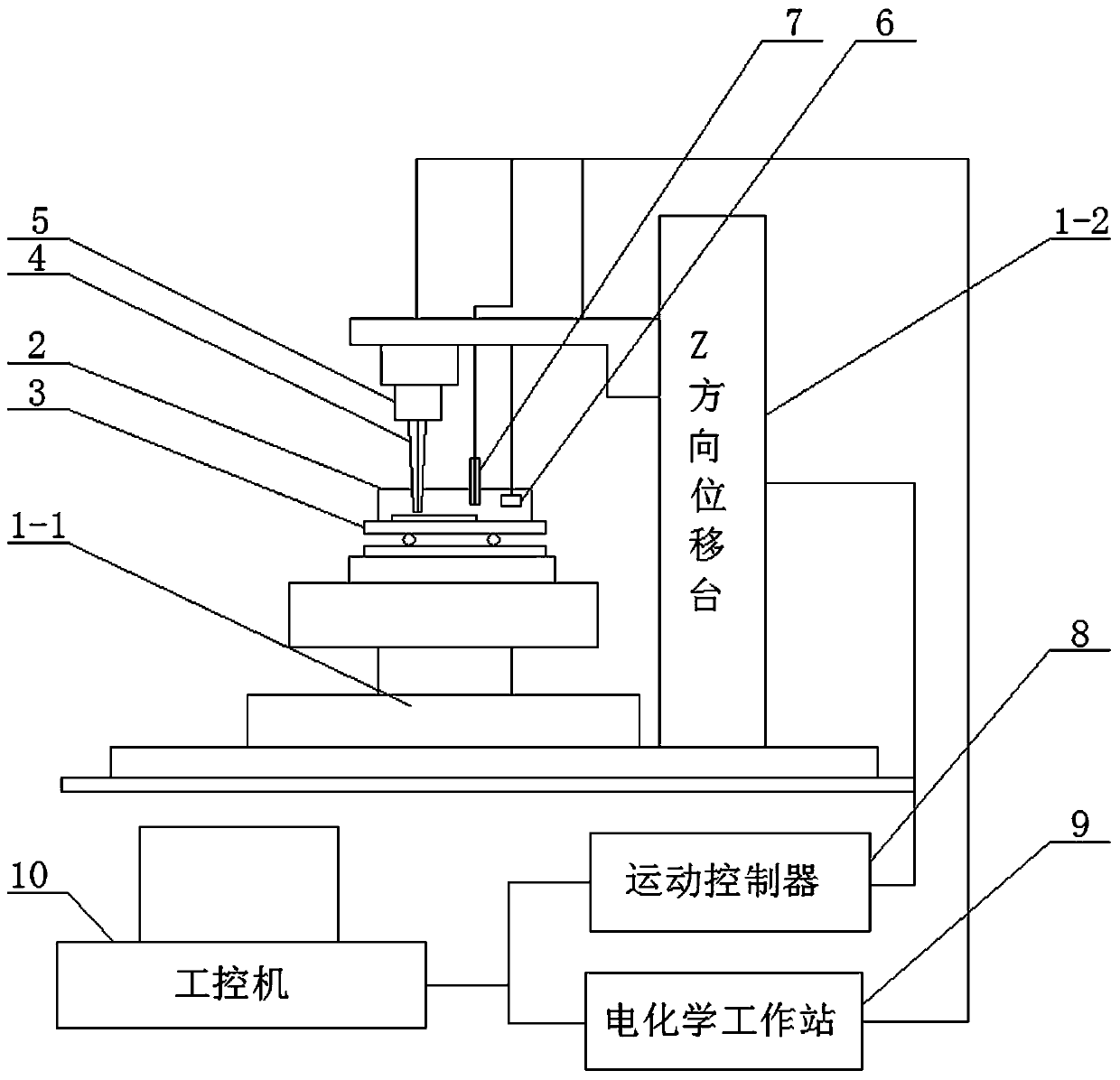

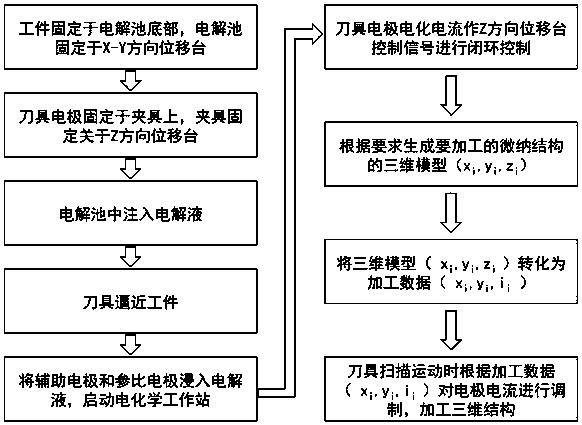

[0031] Specific implementation mode one: as figure 1 and figure 2 As shown, this embodiment describes a three-dimensional micro-nano structure electrochemical induction processing method, and the processing method includes the following steps:

[0032] Step (1): Fix the workpiece 3 to be processed on the bottom of the electrolytic cell 2 in the electrochemical system, and then fix the electrolytic cell 2 on the horizontal displacement table 1-1 in the X-Y direction;

[0033] Step (2): Fixing the micro-nano size cutter electrode 4 (referred to as the cutter electrode) on the fixture 5, and then fixing the fixture 5 on the Z-direction displacement table 1-2;

[0034] Step (3): Inject electrolyte solution into the electrolytic cell 2, so that the electrolyte solution does not pass through the workpiece 3 to be processed;

[0035] Step (4): controlling the micro-nano-sized tool electrode 4 to approach the workpiece 3;

[0036] Step (5): Immerse the auxiliary electrode 6 and th...

specific Embodiment approach 2

[0041] Specific implementation mode two: as figure 2 As shown, this embodiment is a further description of specific embodiment 1. In step (1), the material of the workpiece 3 to be processed is metal or semiconductor; the metal is magnesium, aluminum, iron, titanium, Vanadium or copper, or an alloy of at least two of the above materials; the semiconductor is silicon, germanium, gallium arsenide, gallium phosphide, indium phosphide, zinc sulfide or cadmium telluride, or at least two of the above materials combination.

specific Embodiment approach 3

[0042] Specific implementation mode three: as figure 2As shown, this embodiment is a further description of Embodiment 1. In step (2), the micronano-sized cutter electrode 4 is a platinum metal or platinum-iridium alloy disk electrode with a diameter of 0.01-100 um. In this embodiment, different precision machining can be performed according to the size of the specific micro-nano-sized cutter electrode 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com