Novel high performance acrylic modified polyurethane water-borne wood paint

A water-based wood lacquer and water-based polyurethane technology, applied in the field of wood lacquer, can solve problems such as unacceptable to ordinary consumers, poor wear and chemical resistance, difficult production process, etc. Affordable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

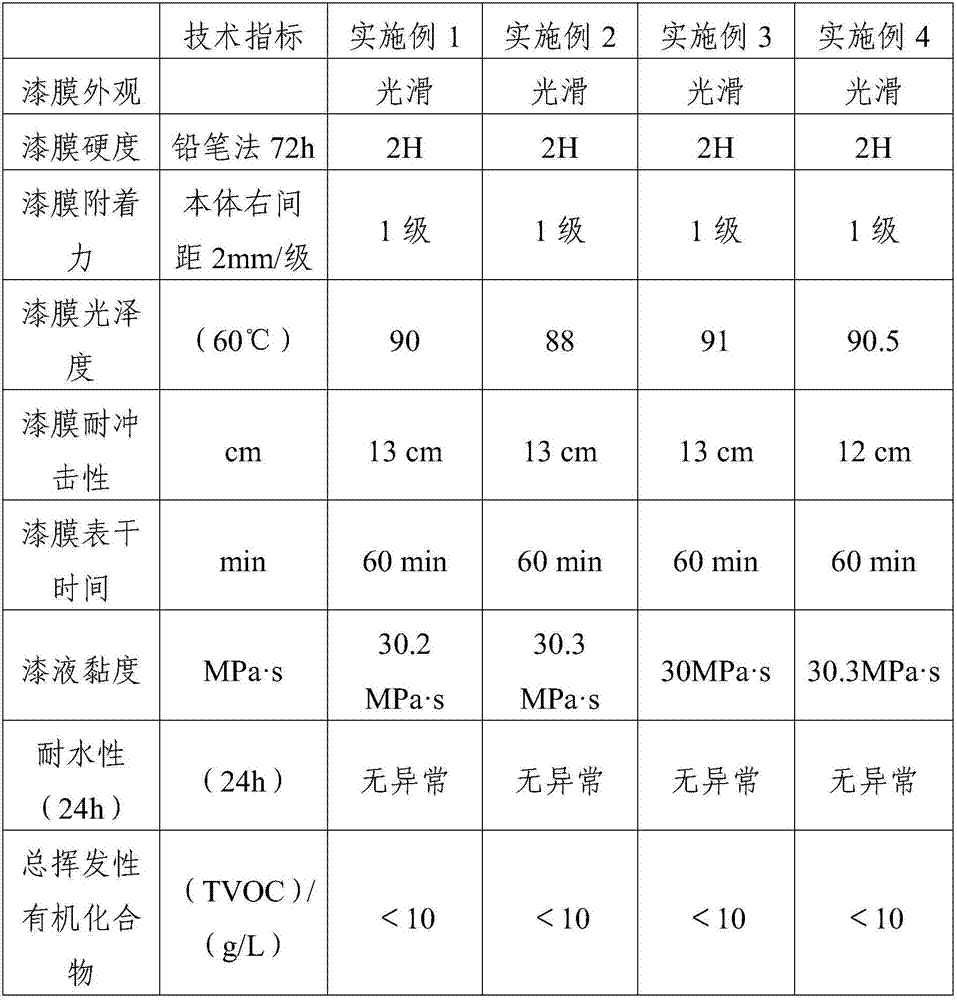

Examples

Embodiment 1

[0021] A new type of high-performance acrylic modified polyurethane water-based wood paint is composed of the following raw materials in parts by weight: 60 parts of acrylic modified polyether-type water-based polyurethane, 10 parts of hexamethylene diisocyanate trimer, and 20 parts of trihydroxymethylpropane 1 part, 1 part of butyltin dilaurate, 0.5 parts of sodium dodecyl sulfonate, 4 parts of propylene glycol phenyl ether, 1.5 parts of polydimethylsiloxane, 1 part of fluorine-modified acrylate, 0.2 parts of sodium hexametaphosphate, 0.3 part of preservative, 0.5 part of anti-aging agent, 20 parts of water, appropriate amount of pH regulator.

[0022] Wherein, the preservative is formed by mixing 5-chloro-2-methyl-4-isothiazolin-3-one and 2-methyl-4-isothiazolin-3-one in a weight ratio of 3:1 .

[0023] Wherein, the anti-aging agent is formed by mixing carbon black and hydroxybenzophenone in a weight ratio of 5:1.

Embodiment 2

[0025] A new type of high-performance acrylic modified polyurethane waterborne wood paint, which is composed of the following raw materials in parts by weight: 80 parts of acrylic modified polyether type waterborne polyurethane, 15 parts of hexamethylene diisocyanate trimer, and 10 parts of trihydroxymethylpropane 5 parts, 5 parts of butyltin dilaurate, 1 part of sodium lauryl sulfonate, 1 part of propylene glycol phenyl ether, 0.5 parts of polydimethylsiloxane, 0.3 parts of fluorine-modified acrylate, 0.1 part of sodium hexametaphosphate, 0.1 part of preservative, 0.2 part of anti-aging agent, 24 parts of water, appropriate amount of pH regulator.

[0026] Wherein, the preservative is formed by mixing 5-chloro-2-methyl-4-isothiazolin-3-one and 2-methyl-4-isothiazolin-3-one in a weight ratio of 1:1 .

[0027] Wherein, the anti-aging agent is formed by mixing carbon black and hydroxybenzophenone in a weight ratio of 4:1.

Embodiment 3

[0029] A new type of high-performance acrylic modified polyurethane waterborne wood paint, which is composed of the following raw materials in parts by weight: 65 parts of acrylic modified polyether type waterborne polyurethane, 20 parts of hexamethylene diisocyanate trimer, and 30 parts of trihydroxymethylpropane 10 parts, 10 parts of butyltin dilaurate, 2 parts of sodium dodecyl sulfonate, 5 parts of propylene glycol phenyl ether, 0.1 part of polydimethylsiloxane, 1.6 parts of fluorine-modified acrylate, 0.6 parts of sodium hexametaphosphate, 0.2 parts of preservative, 0.8 parts of anti-aging agent, 30 parts of water, and appropriate amount of pH regulator.

[0030] Wherein, the preservative is formed by mixing 5-chloro-2-methyl-4-isothiazolin-3-one and 2-methyl-4-isothiazolin-3-one in a weight ratio of 6:1 .

[0031] Wherein, the anti-aging agent is formed by mixing carbon black and hydroxybenzophenone in a weight ratio of 6:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com