High-waterproof adhesive for wood processing and preparation method of adhesive

A high waterproof, adhesive technology, applied in the direction of adhesives, adhesive types, adhesive additives, etc., can solve the problems of high waterproof and adhesive performance requirements of adhesives, easy hydrolysis of ester groups, and poor water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

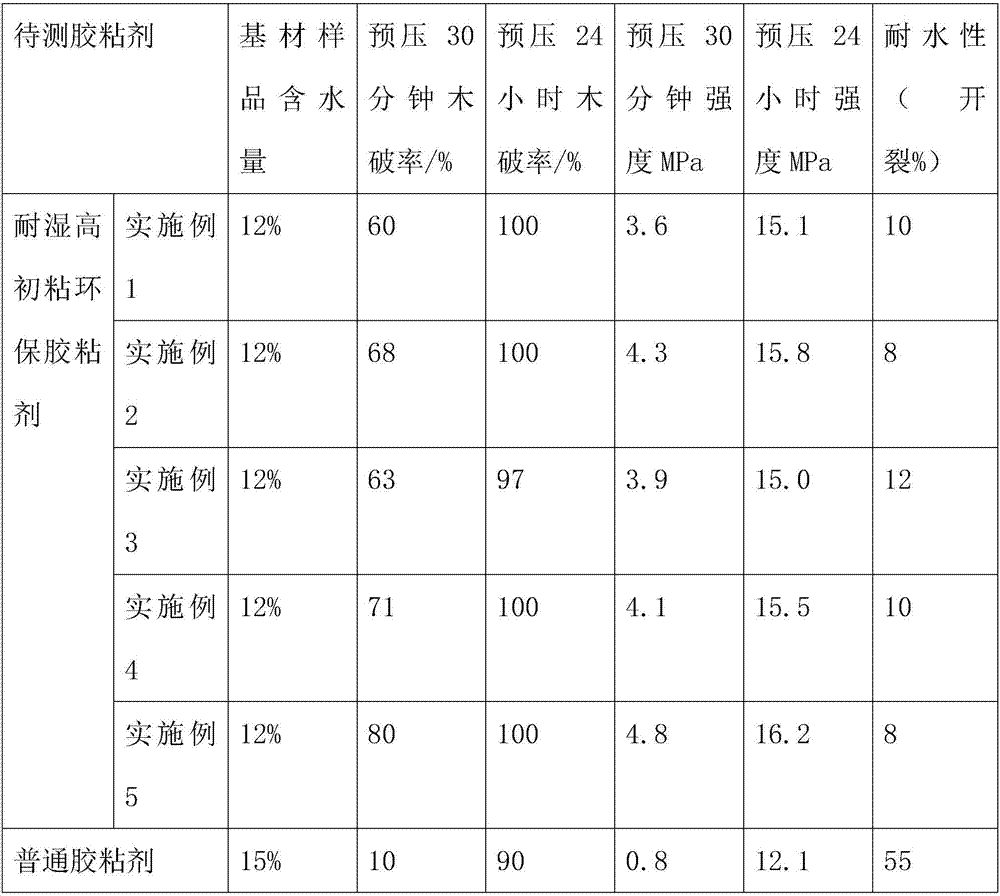

Examples

Embodiment 1

[0018] A kind of high water-repellent adhesive for wood processing proposed by the present invention, its raw material comprises by weight: 100 parts of polyurethane, 4.5 parts of dibutyl phthalate, 12 parts of bromobutyl rubber, 20 parts of SBS resin, 11.5 parts of waste polystyrene foam, 2 parts of silane coupling agent KH-560, 4.5 parts of sodium bisulfite, 3.5 parts of calcium stearate, 2 parts of polydimethylsiloxane, polymethylphenylsiloxane 5 parts, 2 parts of cellulose acetate butyrate, 6 parts of polyvinyl alcohol, 3.5 parts of dimethylethanolamine, 2 parts of diethylene glycol monobutyl ether, 10 parts of toluene, 6 parts of waterproof modifier, 2.5 parts of adhesion enhancer parts, 18 parts of deionized water.

[0019] The waterproof modifier is prepared according to the following process: 6 parts by weight of nano-titanium dioxide, 3.5 parts of antimony trioxide, 2.5 parts of magnetized powder, 4.5 parts of silane coupling agent KH-570 and 6 parts of ethanol are mi...

Embodiment 2

[0026] A kind of high water-repellent adhesive for wood processing proposed by the present invention, its raw material comprises by weight: 80 parts of polyurethane, 6 parts of dibutyl phthalate, 8 parts of bromobutyl rubber, 25 parts of SBS resin, 9 parts of waste polystyrene foam, 3 parts of silane coupling agent KH-560, 3 parts of sodium bisulfite, 5 parts of calcium stearate, 1 part of polydimethylsiloxane, polymethylphenylsiloxane 6 parts, 1 part of cellulose acetate butyrate, 8 parts of polyvinyl alcohol, 2 parts of dimethylethanolamine, 3 parts of diethylene glycol monobutyl ether, 5 parts of toluene, 8 parts of waterproof modifier, 1 part of adhesion enhancer parts, 24 parts of deionized water.

[0027] The waterproof modifier is prepared according to the following process: by weight, 3 parts of nano-titanium dioxide, 5 parts of antimony trioxide, 1 part of magnetized powder, 36 parts of silane coupling agent KH-570 and 4 parts of ethanol are mixed evenly, and heated a...

Embodiment 3

[0034] A kind of highly water-repellent adhesive for wood processing proposed by the present invention, its raw material comprises by weight: 120 parts of polyurethane, 3 parts of dibutyl phthalate, 16 parts of bromobutyl rubber, 15 parts of SBS resin, 14 parts of waste polystyrene foam, 1 part of silane coupling agent KH-560, 6 parts of sodium bisulfite, 2 parts of calcium stearate, 3 parts of polydimethylsiloxane, polymethylphenylsiloxane 4 parts, 3 parts of cellulose acetate butyrate, 4 parts of polyvinyl alcohol, 5 parts of dimethylethanolamine, 1 part of diethylene glycol monobutyl ether, 15 parts of toluene, 4 parts of waterproof modifier, 4 parts of adhesion enhancer parts, 12 parts of deionized water.

[0035] The waterproof modifier is prepared according to the following process: by weight, 9 parts of nano-titanium dioxide, 2 parts of antimony trioxide, 4 parts of magnetized powder, 3 parts of silane coupling agent KH-570 and 8 parts of ethanol are mixed evenly, and h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com