Three-dimensional graphene/silicon composite system, its preparation method and application

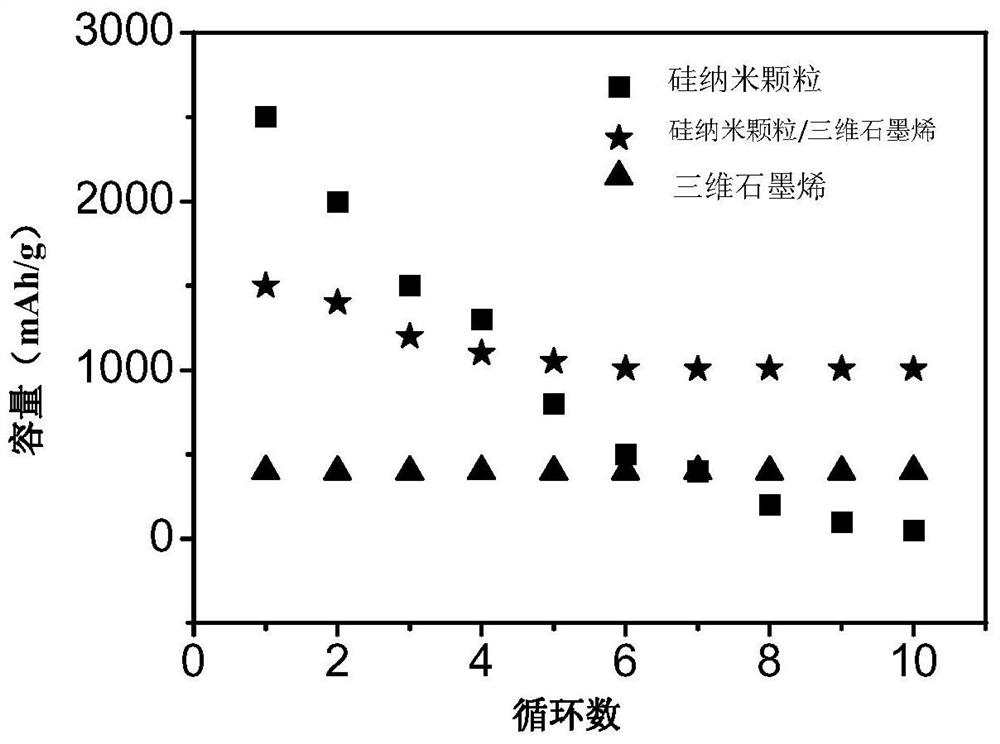

A graphene, three-dimensional technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of low electronic conductivity and large volume effect, and achieve the effect of high electronic conductivity, small volume effect and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A method for preparing a three-dimensional graphene / silicon composite system provided by an aspect of the embodiments of the present invention includes:

[0023] Composite transition metal elemental substance and / or compound containing transition metal elements with silicon nanoparticles, and then carry out high-temperature reduction in a reducing atmosphere at 400-1000°C to prepare a three-dimensional porous metal catalyst template / silicon composite system;

[0024] Using a chemical vapor deposition method to grow three-dimensional graphene on the three-dimensional porous metal catalyst template / silicon composite system to obtain a three-dimensional graphene / silicon composite system with a catalyst skeleton;

[0025] The three-dimensional graphene / silicon composite system with the catalyst skeleton is etched to obtain a three-dimensional graphene / silicon composite powder.

[0026] Further, in the three-dimensional porous metal catalyst template / silicon composite system...

Embodiment 1

[0058] Example 1: Put 20g of nickel chloride into a tube furnace and keep it at 600°C for 10 minutes. The atmosphere is: hydrogen: 300 sccm, argon: 100 sccm. Then raise the tube furnace to 1000°C and keep it at 1000°C for 10 minutes. At this time, the atmosphere is: methane: 30 sccm, hydrogen: 200 sccm, argon: 200 sccm. The quartz tube was taken out and cooled to room temperature. with 1M FeCl 3 / 0.1M HCl for etching to finally obtain three-dimensional graphene powder. Add 0.5g of nano silicon powder, 0.05g of polyvinylpyrrolidone and 0.01g of silane coupling agent KH550 into 10g of N-methylpyrrolidone and sonicate for 1h. After immersing the three-dimensional graphene in the above solution for 30min, take it out and dry it to obtain a three-dimensional graphene / Silicon composite system.

Embodiment 2

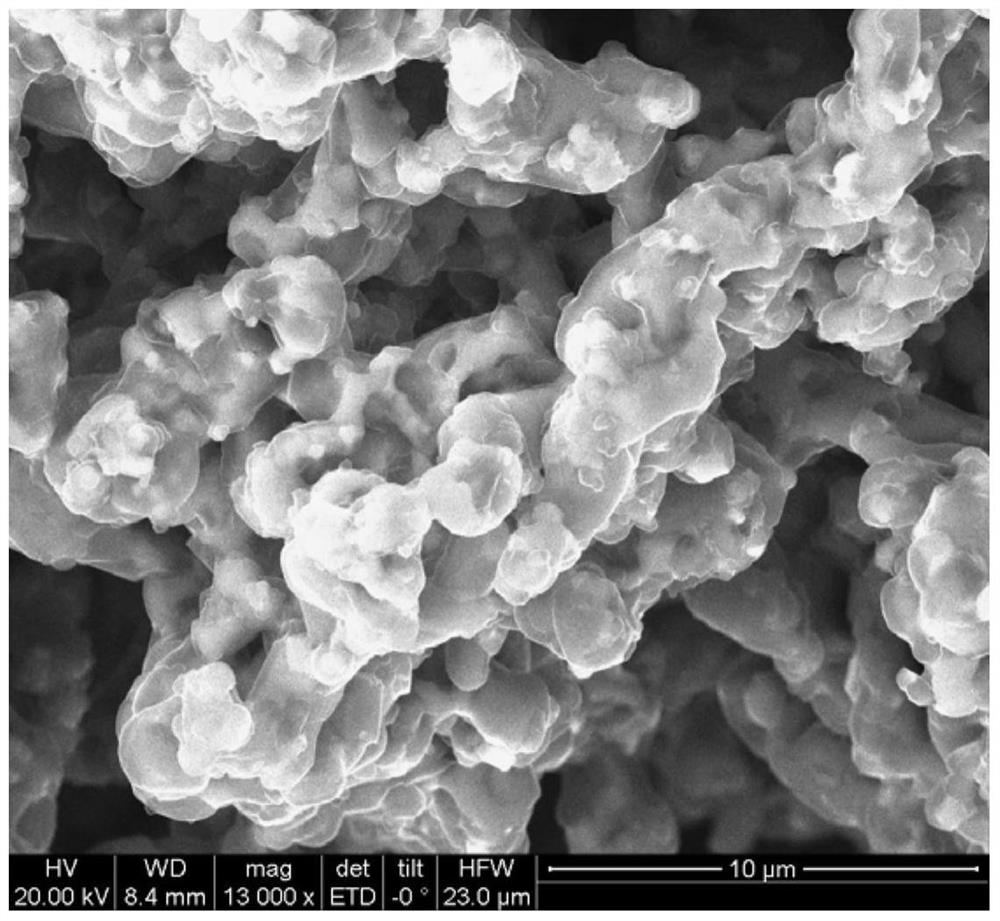

[0059] Example 2: After grinding and mixing 20g of nickel chloride and 0.5g of silicon nanoparticles for 0.5h, they were put into a tube furnace, kept at 600°C for 10 minutes, and the atmosphere was: hydrogen: 300 sccm, argon: 100 sccm. Then raise the tube furnace to 1000°C and keep it at 1000°C for 10 minutes. At this time, the atmosphere is: methane: 30 sccm, hydrogen: 200 sccm, argon: 200 sccm. The quartz tube was taken out and cooled to room temperature. After etching with 3M HCl, washing with water, and drying, a three-dimensional graphene / silicon composite system (such as figure 1 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com