cu 2 o/mwcnts composite materials, preparation methods and electromagnetic wave absorption applications

A composite material and composite material technology, applied in the field of Cu2O/MWCNTs composite material and its preparation, can solve the problems of organic solvent pollution, complicated treatment process, high equipment requirements, etc., achieve excellent microwave absorption performance, simple and convenient preparation method, and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

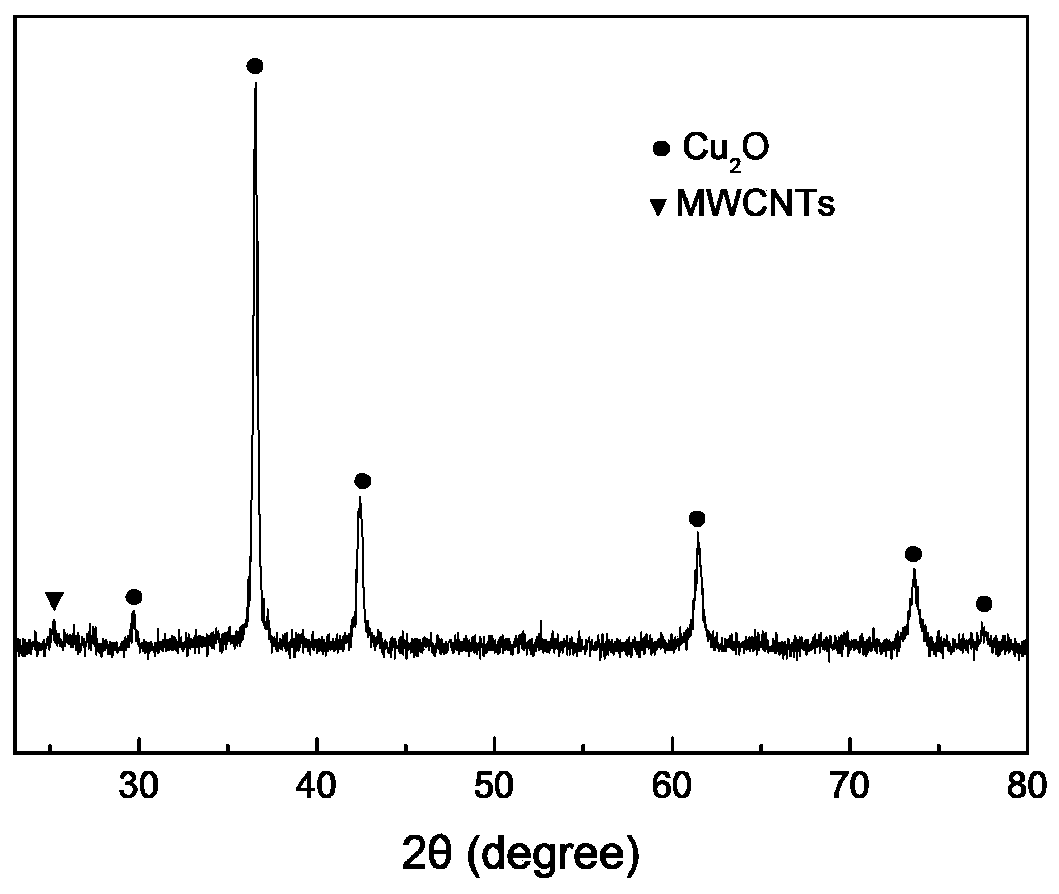

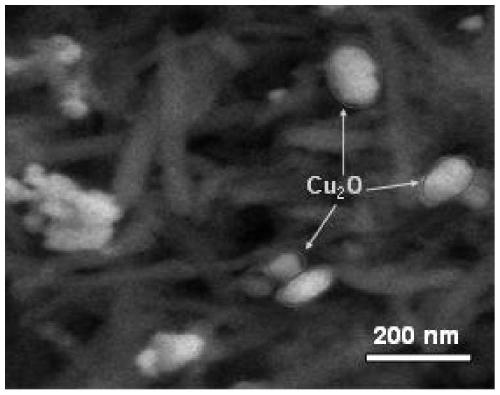

[0048] a Cu 2 O / MWCNTs composite material, the Cu in the composite material 2 O nanoparticles grow disorderly inside and on the surface of MWCNTs.

[0049] The preparation method of Cu2O / MWCNTs composite material: the method steps are as follows:

[0050] 1) Pretreatment of porous-walled carbon nanotubes: Add MWCNTs and concentrated nitric acid sequentially into a 250mL three-necked flask. MWCNTs acidified with concentrated nitric acid;

[0051] 2) Cu 2 Preparation of O / MWCNTs composites: Add MWCNTs to distilled water, ultrasonically disperse for 1 h, and then add CuSO 4 ·5H 2 O and PEG, magnetically stirred until completely dissolved; placed in an ultrasonic reactor and sonicated until the reaction system mixture changed from blue to black, titrated the reacted mixed solution with sodium hydroxide solution to PH = 11, and then magnetically stirred After the reaction, ethanol and distilled water were added to wash several times to obtain solid black particles, and the co...

Embodiment 2

[0065] Cu2 The preparation method of O / MWCNTs composite material: method steps are as follows:

[0066] 1) Pretreatment of porous-walled carbon nanotubes: Add MWCNTs and concentrated nitric acid sequentially into a 250mL three-necked flask. MWCNTs acidified with concentrated nitric acid;

[0067] 2) Cu 2 Preparation of O / MWCNTs composites: Add MWCNTs to distilled water, ultrasonically disperse for 1 h, and then add CuSO 4 ·5H 2 O and PEG, magnetically stirred until completely dissolved; placed in an ultrasonic reactor and sonicated until the reaction system mixture changed from blue to black, titrated the reacted mixed solution with sodium hydroxide solution to PH = 11, and then magnetically stirred After the reaction, ethanol and distilled water were added to wash several times to obtain solid black particles, and the collected solid black particles were dried in an oven at 60°C for 12 hours, and then the obtained flake samples were put into a tube furnace under Calcining...

Embodiment 3

[0075] a Cu 2 O / MWCNTs composite material, the Cu in the composite material 2 O nanoparticles grow disorderly inside the MWCNTs.

[0076] Cu as claimed in claim 1 2 The preparation method of O / MWCNTs composite material: method steps are as follows:

[0077] 1) Pretreatment of porous-walled carbon nanotubes: Add MWCNTs and concentrated nitric acid sequentially into a 250mL three-necked flask. MWCNTs acidified with concentrated nitric acid;

[0078] 2) Cu 2 Preparation of O / MWCNTs composites: Add MWCNTs to distilled water, ultrasonically disperse for 1 h, and then add CuSO 4 ·5H 2 O and PEG, magnetically stirred until completely dissolved; placed in an ultrasonic reactor and sonicated until the reaction system mixture changed from blue to black, titrated the reacted mixed solution with sodium hydroxide solution to PH = 11, and then magnetically stirred After the reaction, ethanol and distilled water were added to wash several times to obtain solid black particles, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com