Carbon dioxide thickening method and system

A carbon dioxide and system technology, applied in chemical instruments and methods, bulk chemical production, drilling compositions, etc., can solve the problems of high cost, insolubility, damage to the surrounding environment and ozone layer, etc., to achieve convenient implementation, Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

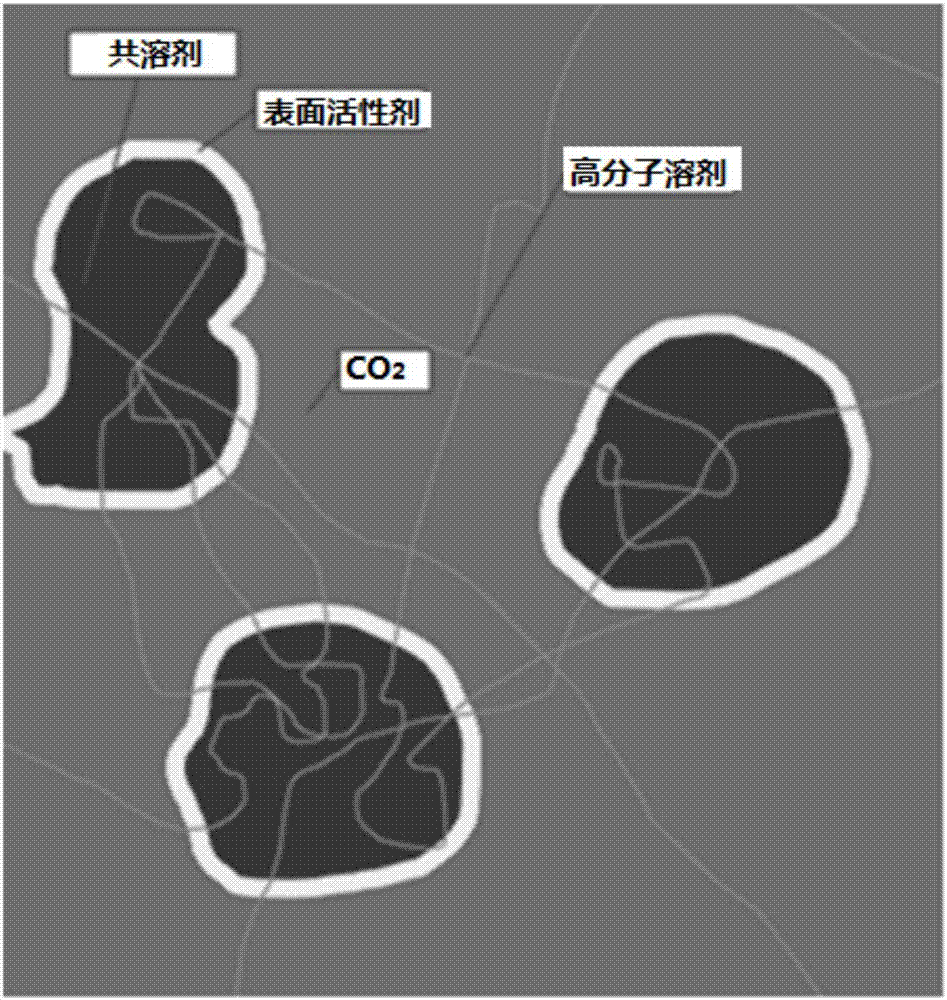

[0045] Ethanol and n-heptane are used as raw materials to design co-solvents. The polymer solvent uses industrially available polyvinyl acetate (PVAc) (number-average molecular weight of 10000) as a direct means of thickening, and the industrial additive butanedioctyl sulfonate Sodium disodium is used as a surfactant.

[0046] Under normal temperature and pressure, the above thickener raw materials ethanol, n-heptane, polyvinyl acetate and succinyl succinate sodium succinate are 2.5%(v / v): 2.5%(v / v):1 %(W / v): 0.5%(w / v) mixing ratio, based on the volume of liquid carbon dioxide.

[0047] A kind of carbon dioxide thickening system can be obtained by fully stirring. When the system is used, it can be mixed with the required liquid or supercritical carbon dioxide and fully stirred to obtain the required viscosity increasing effect.

[0048] The structural formula of sodium diisooctyl succinate sulfonate used in this example is as follows:

[0049]

[0050] The structure of polyvinyl ace...

Embodiment 2

[0053] Use absolute ethanol and n-heptane as raw materials to design co-solvents, use industrially available polyvinyl acetate (PVAc) (number average molecular weight of 20000) as a direct means of thickening, and use industrial additives dioctyl sulfonate Sodium diacid (trade name "Aerosol OT") is used as a surfactant.

[0054] Under normal temperature and pressure, the above thickener raw materials ethanol, n-heptane, polyvinyl acetate (molecular weight 20000) and dioctyl sulfonated sodium succinate are 1% (v / v): 4% (v / v) ): 1% (w / v): 1% (w / v) ratio of mixing, based on the volume of liquid carbon dioxide, fully stirred to obtain a carbon dioxide thickening system. When the system is in use, first heat the system to 120 degrees, then pump CO 2 Up to 17 MPa, and then stirring at 2000 rpm to drop to room temperature, the viscosity was 2.45 mPa·s.

Embodiment 3

[0056] Use methanol and petroleum ether as raw materials to design co-solvents, use industrially available polyvinyl acetate (PVAc) (number average molecular weight of 10000) as a direct means of thickening, and use industrial additives succinyl succinic acid Sodium is used as a surfactant.

[0057] Under normal temperature and pressure, the above thickener raw materials methanol, petroleum ether, polyvinyl acetate and succinate sodium succinate are 2.5% (v / v): 2.5% (v / v): 0.5% (w / v): 1% (w / v), based on the volume of liquid carbon dioxide.

[0058] Under normal temperature and pressure, a carbon dioxide thickening system can be obtained by fully stirring. When the system is used, it can be mixed with the required liquid or supercritical carbon dioxide and fully stirred to obtain the desired viscosity increasing effect. The viscosity is 1.14mPa·s at room temperature and 7.0MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com