Composite material of micro-loaded titanium oxide and silica gel and preparation method thereof

A composite material, titanium oxide technology, applied in chemical instruments and methods, separation methods, silicon compounds, etc., can solve the problems of easy desorption and instability, and achieve the effects of preventing agglomeration, improving efficiency and low process cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0055] Step 1. Preparation of Micro-supported Titanium Oxide Suspension

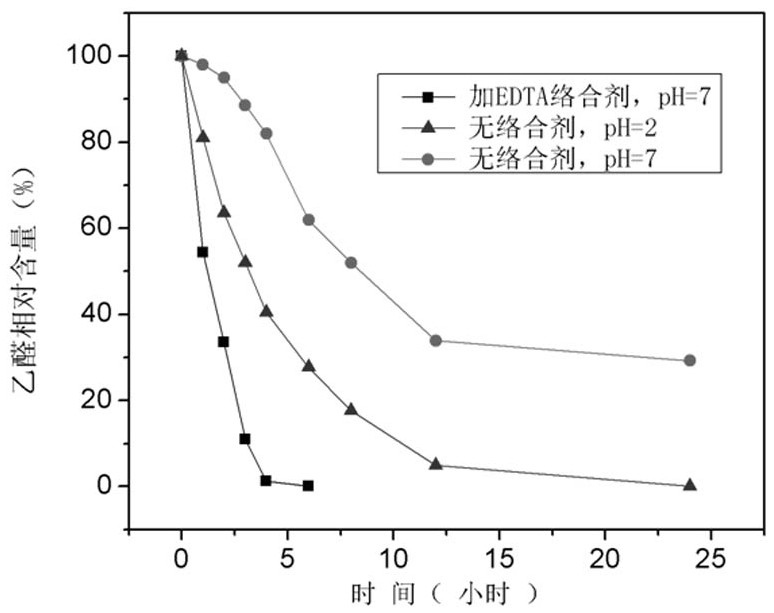

[0056] 1.1. Weigh 5g of the complexing agent ethylenediaminetetraacetic acid disodium salt (EDTA for short) and dissolve it in 100g of deionized water to prepare an EDTA aqueous solution with a concentration of 5%;

[0057] 1.2. Under stirring, weigh 146.5g of copper nitrate and dissolve it in the above EDTA aqueous solution to prepare Cu 2+ Cu at a concentration of 0.5 g / mL 2+ complexing solution;

[0058] 1.3. Add 200g nano mixed crystal titanium oxide to 1000g deionized water, stir for 5 minutes, ultrasonic for 3 minutes, ultrasonic power 200W to make mixed crystal titanium oxide suspension, in which rutile type nano titanium oxide and anatase type nano titanium oxide are mixed. The mass ratio of titanium oxide is 1:1;

[0059] 1.4. Under stirring, add 5 mL of the Cu described in step 1.2 to the 2+ The complex solution is slowly added dropwise to the mixed crystal titanium oxide suspension describ...

Embodiment 3

[0064] Step 1. Preparation of Micro-supported Titanium Oxide Suspension

[0065] 1.1. Weigh 1 g of complexing agent EDTA and dissolve it in 100 g of deionized water to prepare an EDTA aqueous solution with a concentration of 1%;

[0066] 1.2. Under stirring, weigh 29.1 g of ferric chloride and dissolve it in the above-mentioned EDTA aqueous solution to prepare Fe 3+ Fe at a concentration of 0.1 g / mL 3+ complexing solution;

[0067] 1.3. Add 200g nano mixed crystal titanium oxide to 1000g deionized water, stir for 5 minutes, ultrasonic for 3 minutes, ultrasonic power 200W to make mixed crystal titanium oxide suspension, in which rutile type nano titanium oxide and anatase type nano titanium oxide are mixed. The mass ratio of titanium oxide is 1:2;

[0068] 1.4. Under stirring, add 2 mL of Fe 3+ The complex solution is slowly added dropwise to the mixed crystal titanium oxide suspension described in step 1.3, heated to 30~40°C and stirred for 0.5~1h to prepare Fe 3+ / TiO 2...

Embodiment 4

[0078] Step 1. Preparation of Micro-supported Titanium Oxide Suspension

[0079] 1.1. Dissolve the complexing agent sodium gluconate in deionized water to prepare an aqueous solution of sodium gluconate with a concentration of 10%;

[0080] 1.2. Under stirring, dissolve silver nitrate in sodium gluconate aqueous solution to prepare Ag + Ag at a concentration of 0.01g / ml + complexing solution;

[0081] 1.3. Add 200g nano mixed crystal titanium oxide to 1000g deionized water, stir for 5 minutes, ultrasonic for 3 minutes, ultrasonic power 200W to make mixed crystal titanium oxide suspension, in which rutile type nano titanium oxide and anatase type nano titanium oxide are mixed. The mass ratio of titanium oxide is 1:10;

[0082] 1.4. Under stirring, the Ag + The complexing solution was slowly added dropwise to the mixed crystal titanium oxide suspension to make Ag + / TiO 2 The mass ratio is 1 / 1000, and the reaction is stirred at 30-35° C. for 1 hour to obtain a micro-suppor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com