Desulfurization wastewater softening pretreatment equipment and treatment method thereof

A technology for desulfurization wastewater and pretreatment, which is applied in gaseous discharge wastewater treatment, water/sewage treatment, chemical instruments and methods, etc. cycle, saving consumption, reducing the effect of operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

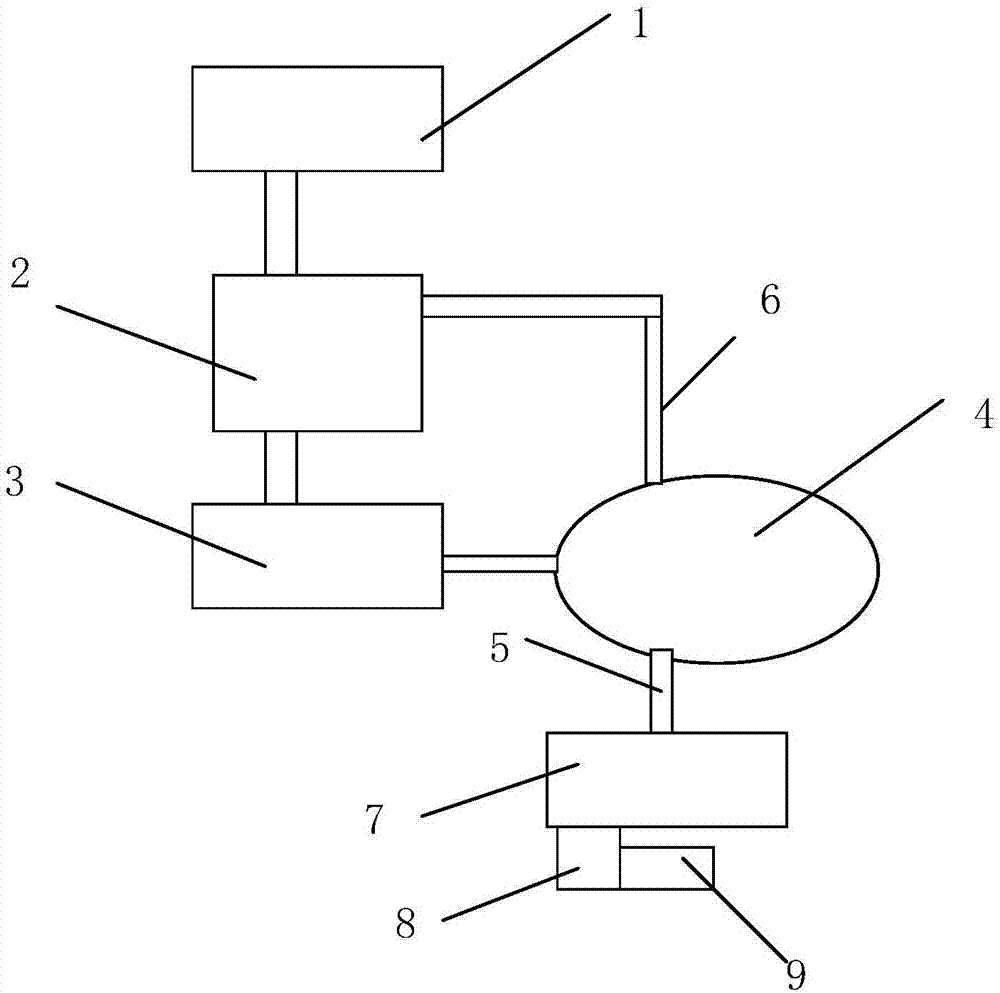

[0044] like figure 1The desulfurization wastewater softening and pretreatment equipment includes a primary reaction tank 1, which is different in that: the discharge port of the primary reaction tank 1 is connected to the first feed port of the dehydration device 2. At the same time, in order to realize orderly graded wastewater treatment, a secondary reaction tank 3 is connected to the outlet of the dehydration device 2 . Moreover, a filtering device 4 is connected to the outlet of the secondary reaction tank 3 to complete the necessary filtering process. In consideration of effective utilization of the sludge during the treatment period, realizing resource recycling an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com