Composite material and application of a facility vegetable field blocking nitrogen and phosphorus leaching loss

A technology of composite materials and facilities, applied in the fields of application, ammonium orthophosphate fertilizer, alkaline orthophosphate fertilizer, etc., can solve problems such as less research, achieve the effects of easy availability of raw materials, improvement of resource utilization efficiency, and reduction of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

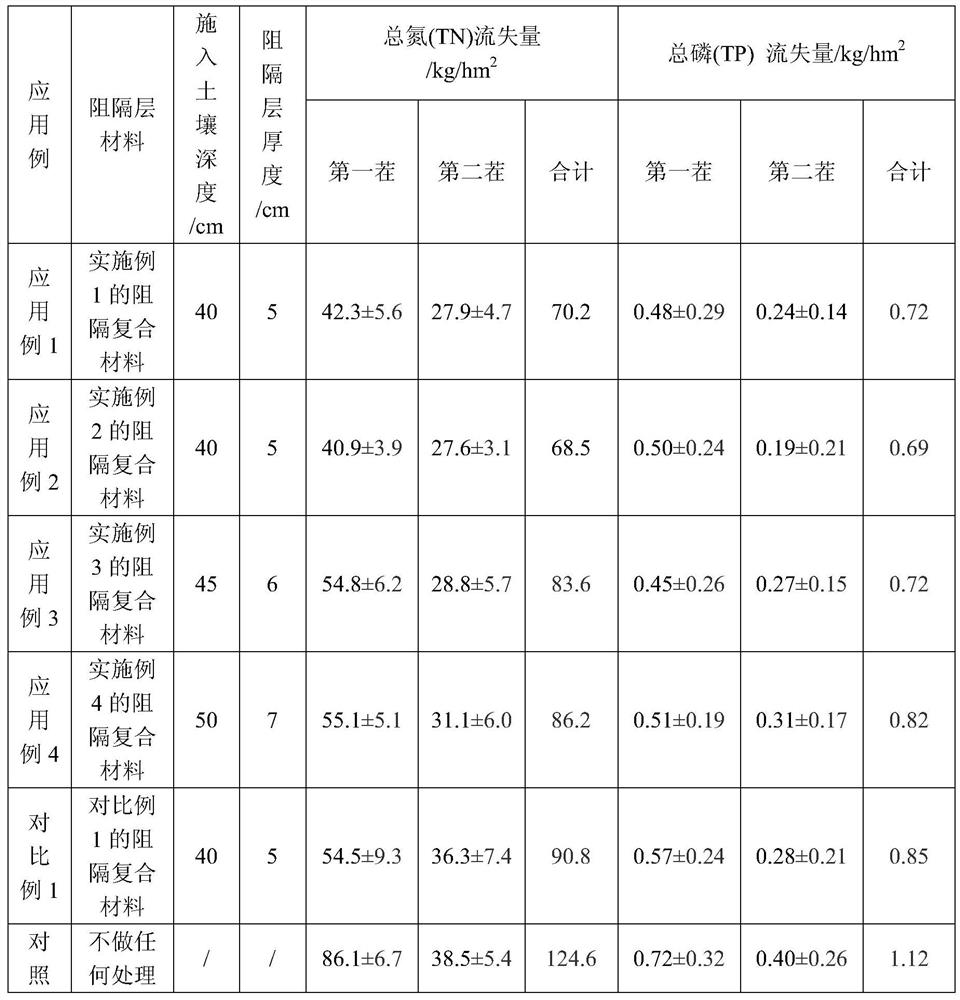

Examples

Embodiment 1

[0036] Embodiment 1. A barrier composite material for preventing and controlling nitrogen and phosphorus leaching loss, comprising the following components in parts by weight: 20 parts of attapulgite powder, 20 parts of sodium pyrophosphate, 35 parts of activated weathered coal, and edible fungus residue 20 parts, 5 parts of iron powder, 15 parts of struvite, 1 part of sucrose.

[0037] The preparation method is:

[0038] (1) Preparation of activated weathered coal: crush the weathered coal through a 2mm sieve, mix the weathered coal, ammonium bicarbonate and ammonium phosphate in a weight ratio of 100:20:5, adjust the humidity to a water content of 40%, mix well and seal at room temperature , placed for 10 to 24 hours, the activated weathered coal with a humic acid content of 58.6% is obtained;

[0039] (2) Weigh the attapulgite powder, sodium pyrophosphate, activated weathered coal, edible fungus slag, iron powder, struvite, and sucrose according to the above parts by weigh...

Embodiment 2

[0040] Embodiment 2. A barrier composite material for preventing and controlling nitrogen and phosphorus leaching loss, comprising the following components in parts by weight: 25 parts of attapulgite powder, 15 parts of sodium pyrophosphate, 40 parts of activated weathered coal, and edible fungus residue 15 parts, 4 parts of iron powder, 18 parts of struvite, 1.5 parts of sucrose.

[0041] The preparation method is:

[0042] (1) Preparation of activated weathered coal: crush the weathered coal through a 2mm sieve, mix weathered coal, ammonium bicarbonate and ammonium phosphate in a weight ratio of 100:15:4, adjust the humidity to a water content of 45%, mix well and seal at room temperature , placed for 10-24 hours, that is, activated weathered coal with a humic acid content of 64.7%;

[0043] (2) Weigh the attapulgite powder, sodium pyrophosphate, activated weathered coal, edible fungus slag, iron powder, struvite, and sucrose according to the above parts by weight, and stir...

Embodiment 3

[0044] Embodiment 3. A barrier composite material for preventing and controlling nitrogen and phosphorus leaching loss, comprising the following components in parts by weight: 28 parts of attapulgite powder, 10 parts of sodium pyrophosphate, 45 parts of activated weathered coal, and edible fungus residue 10 parts, 2 parts of iron powder, 20 parts of struvite, 2 parts of sucrose.

[0045] The preparation method is:

[0046] (1) Preparation of activated weathered coal: crush the weathered coal through a 2mm sieve, mix weathered coal, ammonium bicarbonate and ammonium phosphate in a weight ratio of 100:10:2, adjust the humidity to a water content of 35%, mix well and seal at room temperature , placed for 10-24 hours, that is, activated weathered coal with a humic acid content of 54.2%;

[0047] (2) Weigh the attapulgite powder, sodium pyrophosphate, activated weathered coal, edible fungus slag, iron powder, struvite, and sucrose according to the above parts by weight, and stir e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com