Hydrophobic emulsified asphalt waterproof coating and preparation method thereof

A technology of emulsified asphalt and waterproof coatings, applied in asphalt coatings, antifouling/underwater coatings, coatings, etc., can solve the problems of easy pollution of waterproof coatings, shortening the service life of bridges and other buildings, and the inability to fully guarantee the quality of projects, etc. , to improve the performance of aging resistance and oil resistance, improve the bonding strength and use effect, improve the actual effect and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

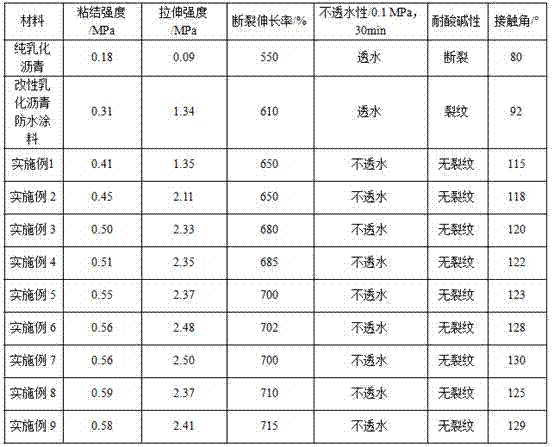

Examples

Embodiment 1

[0023] According to the mass ratio of each component, mix 2 parts of polyvinyl alcohol, 0.6 parts of dodecyltrimethylammonium chloride, 20 parts of SBR powder, 10 parts of CR powder, and 45 parts of water at 60 ° C. Heating 45 parts of asphalt to 135°C, the above two parts were uniformly mixed through a colloid mill at a high speed in proportion, and then hydrophobic nano-SiO was added 2 10 parts of filler, micron CaCO 3 5 parts of filler, 45 parts of anhydrous methanol and 0.6 part of tert-butyl anisole were dispersed at a high speed of 1800r / min to prepare a hydrophobic emulsified asphalt waterproof coating.

Embodiment 2

[0025] According to the mass ratio of each component, mix 2 parts of polyvinyl alcohol, 0.6 parts of dodecyltrimethylammonium chloride, 25 parts of SBR powder, 10 parts of CR powder, and 45 parts of water at 65 °C and mix evenly, 90# Heating 45 parts of asphalt to 135°C, the above two parts were uniformly mixed through a colloid mill at a high speed in proportion, and then hydrophobic nano-SiO was added 2 10 parts of filler, micron CaCO 3 8 parts of filler, 45 parts of anhydrous methanol, and 0.6 part of tert-butyl anisole were dispersed at a high speed of 2500r / min to prepare a hydrophobic emulsified asphalt waterproof coating.

Embodiment 3

[0027] According to the mass ratio of each component, mix 2 parts of polyacrylamide, 0.8 part of dodecyltrimethylammonium chloride, 25 parts of SBR powder, 15 parts of CR powder, and 45 parts of water at 65 ° C, 90# Heating 50 parts of asphalt to 130°C, the above two parts were uniformly mixed through a colloid mill at a high speed and sheared at a uniform rate in proportion, and then hydrophobic nano-SiO was added 2 Filler 15 parts, micron CaCO 3 10 parts of filler, 45 parts of anhydrous methanol, and 0.6 part of tert-butyl anisole were dispersed at a high speed of 2200r / min to prepare a hydrophobic emulsified asphalt waterproof coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com