Wood protective agent and production method thereof

A production method and protective agent technology, applied in wood treatment, wood impregnation, wood impregnation, etc., can solve the problems of high solvent volatility, influence on reprocessing, human hazards, etc., achieve stable chemical properties, protect wood, and excellent water resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

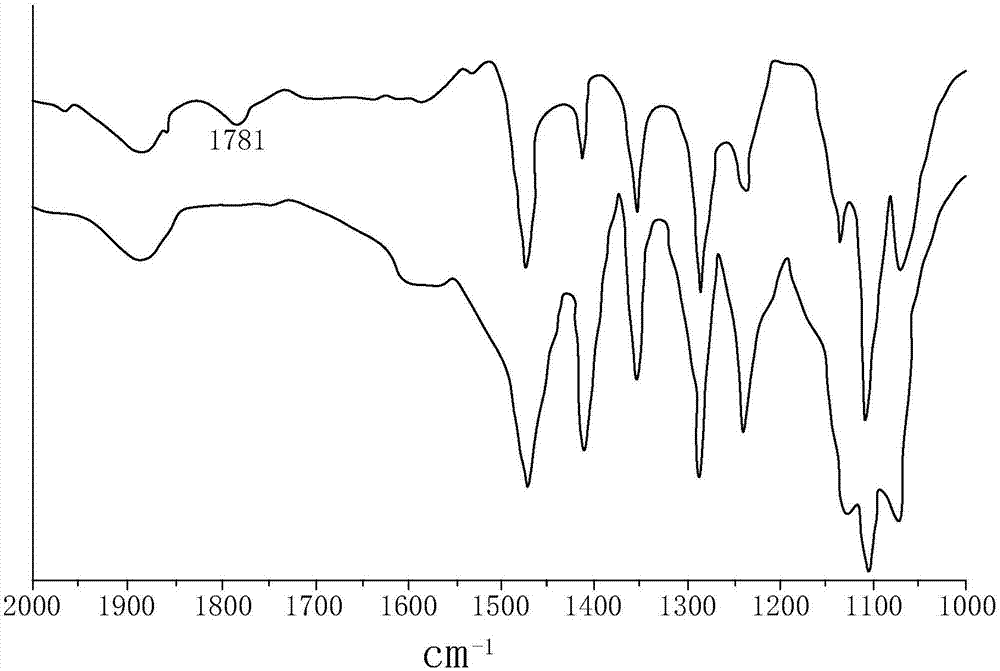

Image

Examples

Embodiment 1

[0034] Embodiment one: wood protection agent, its raw material comprises:

[0035] Perfluoro group denatured polyvinyl alcohol 50Kg;

[0036] Nano silicon dioxide 20Kg;

[0037] Quaternary ammonium cationic fluorocarbon surfactant 1Kg;

[0038] Ethanol 8Kg;

[0039] Sodium monofluorophosphate 1.5Kg;

[0040] Deionized water 120Kg;

[0041] Wherein, in the perfluorinated polyvinyl alcohol, x=3, y=7, m:n=3:1.

[0042] The production method of wood protection agent is as follows:

[0043] Step A: Synthesis of perfluorinated polyvinyl alcohol

[0044] In parts by weight, under the condition of nitrogen protection, polyvinyl alcohol with a degree of polymerization of 800 is added to dimethylformamide solution, heated to 200°C under vigorous stirring, and cooled to 90°C after the polyvinyl alcohol is completely dissolved. After adding pyridine, slowly add CF 3 (CF 2 ) 3 COCl, then slowly add CF 3 (CF 2 ) 7 COCl, reacted for 5 hours, the product was precipitated by aceto...

Embodiment 2

[0047] Embodiment two: wood protection agent, its raw material comprises:

[0048] Perfluoro group denatured polyvinyl alcohol 55Kg;

[0049] Nano silicon dioxide 15Kg;

[0050] Quaternary ammonium cationic fluorocarbon surfactant 1.2Kg;

[0051] Ethanol 10Kg;

[0052] Sodium monofluorophosphate 1Kg;

[0053] Deionized water 110Kg;

[0054] Wherein, in the perfluorinated polyvinyl alcohol, x=3, y=7, m:n=3:1.

[0055] The production method of wood protection agent is as follows:

[0056] Step A: Synthesis of perfluorinated polyvinyl alcohol

[0057] In parts by weight, under the condition of nitrogen protection, polyvinyl alcohol with a degree of polymerization of 750 is added to dimethylformamide solution, heated to 200°C under vigorous stirring, and cooled to 90°C after the polyvinyl alcohol is completely dissolved. After adding pyridine, slowly add CF 3 (CF 2 ) 3 COCl, then slowly add CF 3 (CF2 ) 7 COCl, reacted for 5 hours, the product was precipitated by aceton...

Embodiment 3

[0059] Embodiment three: wood protection agent, its raw material comprises:

[0060] Perfluoro group denatured polyvinyl alcohol 60Kg;

[0061] Nano silicon dioxide 18Kg;

[0062] Quaternary ammonium cationic fluorocarbon surfactant 1.5Kg;

[0063] Ethanol 5Kg;

[0064] Sodium monofluorophosphate 1.3Kg;

[0065] Deionized water 115Kg;

[0066] Wherein, in the perfluorinated polyvinyl alcohol, x=3, y=7, m:n=3:1.

[0067] The production method of wood protection agent is as follows:

[0068] Step A: Synthesis of perfluorinated polyvinyl alcohol

[0069] In parts by weight, under the condition of nitrogen protection, polyvinyl alcohol with a degree of polymerization of 900 is added to dimethylformamide solution, heated to 200°C under vigorous stirring, and cooled to 90°C after the polyvinyl alcohol is completely dissolved. After adding pyridine, slowly add CF 3 (CF 2 ) 3 COCl, then slowly add CF 3 (CF 2 ) 7 COCl, reacted for 5 hours, the product was precipitated by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com