Treatment device and method of electrolytic aluminum carbon anode roasting flue gas and usage

A carbon anode and electrolytic aluminum technology, applied in the field of pollutant control, can solve the problems of high capital construction investment and maintenance costs, no purification effect, equipment corrosion, etc., and achieve the effects of small footprint, thorough removal, and improved absorption efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

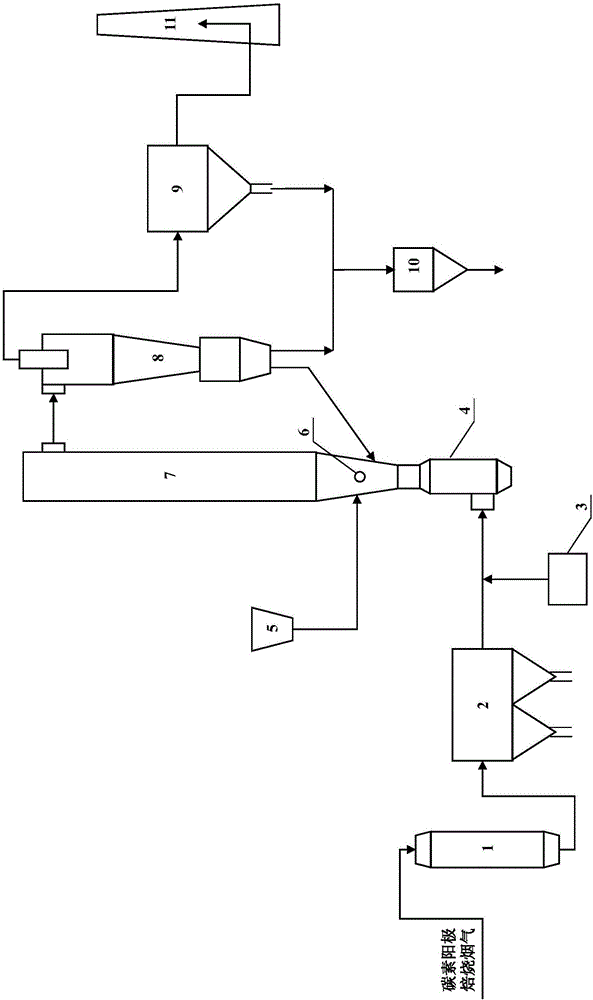

[0053] An electrolytic aluminum carbon anode roasting flue gas desulfurization, defluorination and deasphalting fume device, including a flue gas cooling system 1, an electric tar catcher 2, a pre-oxidation system 3, and a semi-dry purification system 4 connected in sequence, and the flue gas is cooled The outlet of system 1 is connected to the inlet of electric tar catcher 2, the outlet of electric tar catcher 2 is connected to the inlet of semi-dry purification system 4, and the intermediate flue of electric tar catcher 2 and semi-dry purification system 4 is provided with pre-oxidation system 3.

[0054] The flue gas cooling system 1 is composed of a full evaporative cooling tower, water pump, conveying pipeline, spray gun, and PLC control system. The electric tar collector 2 is a horizontal double electric field electrostatic precipitator. The pre-oxidation system 3 is composed of an oxidant supply device, a dilution fan, and a buffer The semi-dry purification system 4 cons...

Embodiment 2

[0062] Utilize the device described in embodiment 1, to the roasting flue gas purification of 100,000 tons / year carbon anode production plant:

[0063] The flue gas volume is 100000m 3 / h, the initial flue gas temperature is 150°C, SO 2 The concentration is 300mg / m 3 , NO x The concentration is 80mg / m 3 , the fluoride concentration is 50mg / m 3 , asphalt smoke concentration is 200mg / m 3 . The flue gas is cooled to 100°C through the flue gas cooling system, ozone is used as the oxidant, and fly ash is used as the absorbent. Processed SO 2 The concentration is 10mg / m 3 , NO x The concentration is 10mg / m 3 , the fluoride concentration is 2.5mg / m 3 , asphalt smoke concentration is 3.5mg / m 3 .

Embodiment 3

[0065] Utilize the device described in embodiment 1, to the roasting flue gas purification of 60,000 tons / year carbon anode production plant:

[0066] The flue gas volume is 50000m 3 / h, the initial flue gas temperature is 180°C, SO 2 The concentration is 500mg / m 3 , NO x The concentration is 120mg / m 3 , the fluoride concentration is 80mg / m 3 , asphalt smoke concentration is 300mg / m 3 . The flue gas is cooled to 90°C through the flue gas cooling system, hydrogen peroxide is used as the oxidant, and a mixed absorbent with a mass ratio of fly ash and lime of 1:1 is used. Processed SO 2 The concentration is 8mg / m 3 , NO x The concentration is 15mg / m 3 , the fluoride concentration is 2mg / m 3 , asphalt smoke concentration is 5mg / m 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com