Method for producing waste liquid separated puerarin by the aid of pueraria starch

A technology for the separation of puerarin starch and waste liquid, applied in the direction of organic chemistry, etc., can solve the problems of low puerarin content, difficult filtration, affecting the production of puerarin, etc., and achieve the effect of large adsorption capacity and high separation purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

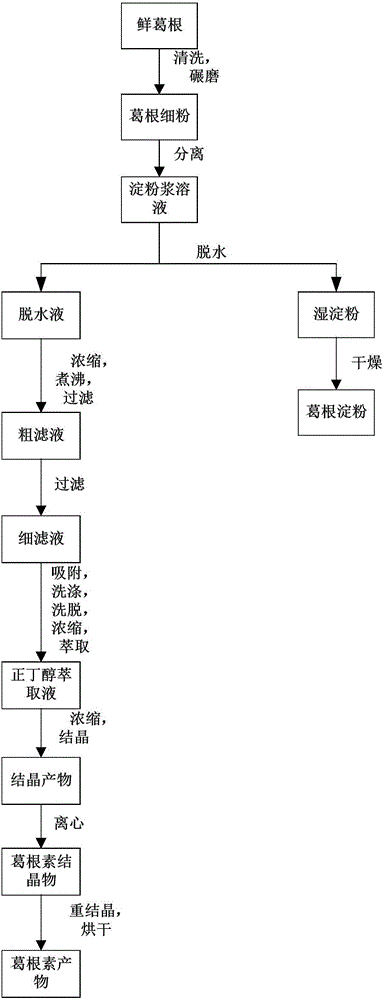

Image

Examples

example 1

[0041] Take by weighing 300 kg of fresh Pueraria lobata, use the paddle cleaning machine to clean the fresh Pueraria lobata, wash off the silt and other sundries on the fresh Pueraria lobata, and then use the coarse rasp mill and the fine rasp mill to grind the fresh Pueraria lobata to obtain fine Pueraria lobata. powder; use a centrifugal sieve to separate pueraria fine powder and slag slurry to remove impurities such as coarse fibers to obtain a starch slurry solution; use a vacuum dehydrator to dehydrate the starch slurry solution to obtain wet starch and dehydration liquid, and use a drying system to dry the wet starch. Dry to obtain kudzu root starch; use a double-effect concentrator to concentrate the dehydrated liquid to obtain a concentrated dehydrated liquid, boil the concentrated dehydrated liquid for 10 minutes, and then filter to remove high-temperature deformed substances such as protein to obtain a crude filtrate; use a plate frame Filter the coarse filtrate to ob...

example 2

[0043] Take by weighing 350kg of fresh Pueraria lobata, utilize the paddle cleaning machine to clean the fresh Pueraria lobata, wash off the silt and other sundries on the fresh Pueraria lobata, then utilize the coarse rasp mill and the fine rasp mill to grind the fresh Pueraria lobata to obtain fine Pueraria lobata. powder; use a centrifugal sieve to separate pueraria fine powder and slag slurry to remove impurities such as coarse fibers to obtain a starch slurry solution; use a vacuum dehydrator to dehydrate the starch slurry solution to obtain wet starch and dehydration liquid, and use a drying system to dry the wet starch. Dry to obtain kudzu root starch; use double-effect concentrator to concentrate the dehydration liquid to obtain concentrated dehydration liquid, boil the concentrated dehydration liquid for 12 minutes, and then filter to remove high-temperature deformation substances such as protein to obtain crude filtrate; Filter the coarse filtrate to obtain the fine f...

example 3

[0045]Take by weighing 400kg of fresh Pueraria lobata, use the paddle cleaning machine to clean the fresh Pueraria lobata, wash off the silt and other sundries on the fresh Pueraria lobata, then use the coarse rasp mill and the fine rasp mill to grind the fresh Pueraria lobata, to obtain fine Pueraria lobata. powder; use a centrifugal sieve to separate pueraria fine powder and slag slurry to remove impurities such as coarse fibers to obtain a starch slurry solution; use a vacuum dehydrator to dehydrate the starch slurry solution to obtain wet starch and dehydration liquid, and use a drying system to dry the wet starch. Dry to obtain kudzu root starch; use a three-effect concentrator to concentrate the dehydrated liquid to obtain a concentrated dehydrated liquid, boil the concentrated dehydrated liquid for 15 minutes, and then filter to remove high-temperature deformed substances such as protein to obtain a crude filtrate; use a plate frame Filter the coarse filtrate to obtain t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com