Preparing method for carbon cloth load Ni-S-Se nanosheet array

A nanosheet array and nanosheet technology, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve the effects of uniform product shape and size, simple and easy process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

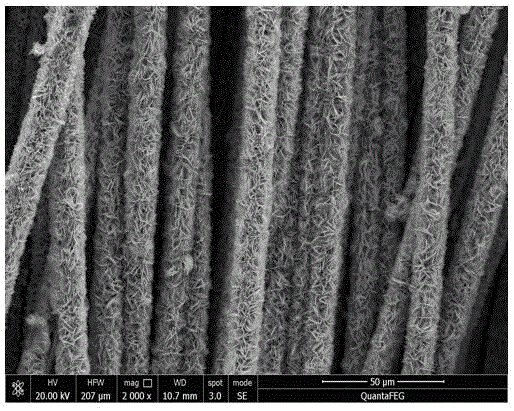

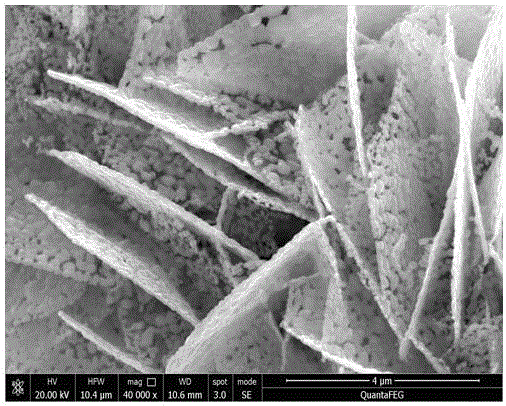

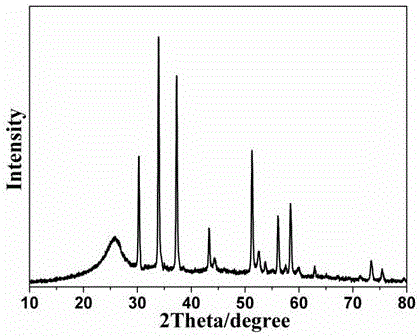

[0023] First mix nickel nitrate with a concentration of 0.05 moles per liter, ammonium fluoride with 0.1 moles per liter and 0.25 moles per liter of urea aqueous solution, then transfer to a polytetrafluoroethylene reactor and add a pre-cut 1*4 cm strip carbon cloth. The above reactants were reacted in an oven at 120 degrees Celsius for 6 hours, and the carbon cloth-supported Ni(OH) was obtained after naturally cooling down to room temperature. 2 Nanosheet arrays. The Ni(OH) supported by the above carbon cloth 2 The nanosheet array was placed on one end of the quartz boat, and 80 mg of a mixture of sulfur powder and selenium powder in a molar ratio of 1:3 was placed on the other end. Put the quartz boat into the high-temperature tube furnace protected by nitrogen, pay attention to place the end containing the mixture of sulfur powder and selenium powder in the direction of the upper airflow, and raise the temperature of the tube furnace to 450 degrees Celsius at a heating ra...

Embodiment 2

[0025] First mix nickel nitrate with a concentration of 0.05 moles per liter, ammonium fluoride with 0.1 moles per liter and 0.25 moles per liter of urea aqueous solution, then transfer to a polytetrafluoroethylene reactor and add a pre-cut 1*4 cm strip carbon cloth. The above reactants were reacted in an oven at 110 degrees Celsius for 10 hours, and the carbon cloth-supported Ni(OH) was obtained after naturally cooling down to room temperature. 2 Nanosheet arrays. The Ni(OH) supported by the above carbon cloth 2 The nanosheet array was placed on one end of the quartz boat, and 100 mg of a mixture of sulfur powder and selenium powder in a molar ratio of 1:3 was placed on the other end. Put the quartz boat into a high-temperature tube furnace protected by nitrogen, pay attention to placing the end of the mixture of sulfur powder and selenium powder in the direction of the upper airflow, and raise the temperature of the tube furnace to 450 at a rate of 10 degrees Celsius per m...

Embodiment 3

[0027] Using Chenhua 660D electrochemical workstation to load Ni(S 0.41 Se 0.59 ) 2 The catalytic activity of nanosheet arrays for electrolysis of water was tested. Platinum wire was used as the counter electrode, silver / silver chloride was used as the reference electrode, and carbon cloth was loaded with Ni(S 0.41 Se 0.59 ) 2 The nanosheet array is the working electrode, and the 1.0 mole per liter KOH aqueous solution is the electrolyte solution. In the voltage range from -0.6 to 0.2 V, linear voltammetry scans were performed at a scan rate of 5 mA per second to obtain carbon cloth supported Ni(S 0.41 Se 0.59 ) 2 Polarization curves of nanosheet array-catalyzed water electrolysis for hydrogen production.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com