Method of boron nitride nanoparticle fabrication for antitumor drug delivery

An anticancer drug and nanoparticle technology, applied in the field of nanomedicine, can solve the problems of low intake, toxicity, and unfavorable cell absorption of boron nitride, so as to avoid cytotoxicity and increase efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

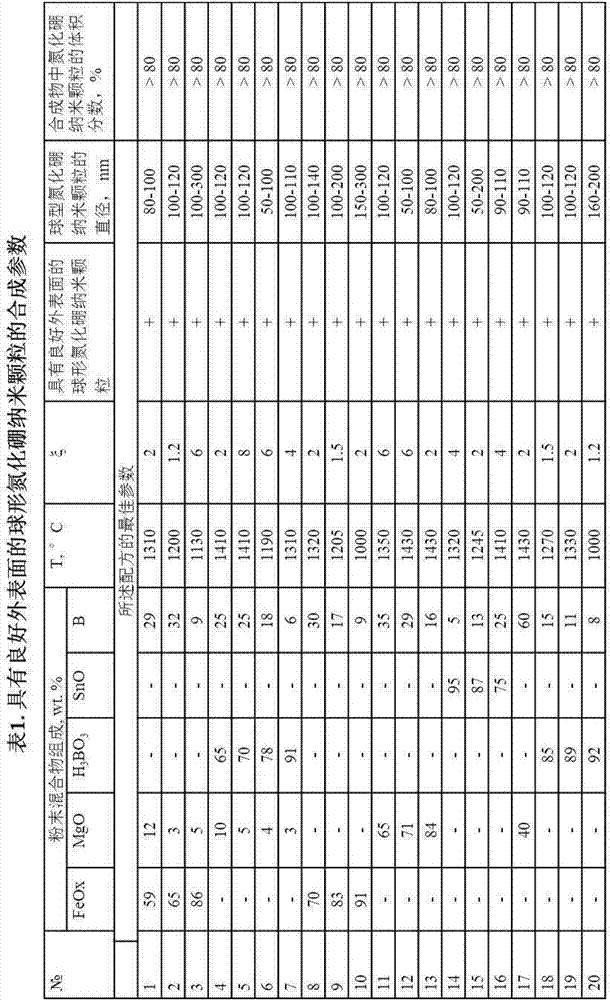

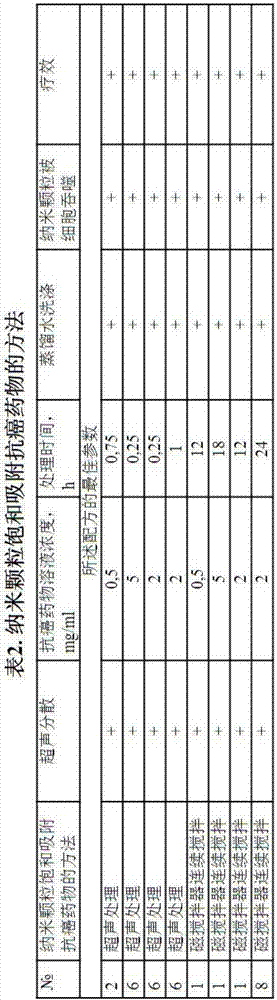

Method used

Image

Examples

Embodiment 1

[0082] Spherical boron nitride nanoparticles were synthesized by chemical vapor deposition in a vertical induction furnace VIN-1,6-20 (Vac ETO, Russia). A powder mixture (10.88g in mass) containing 59wt.% iron oxide, 12wt.% magnesia and 29wt.% amorphous boron was thoroughly mixed and evenly put into a crucible, which was then placed in a furnace. The working chamber of the reactor is heated to 300°C, and the water and oxygen adsorbed on the surface of the working chamber are removed by using a permanent vacuum pump. The chamber was then filled with argon to atmospheric pressure. After the furnace was heated to 850°C, the transport gas argon and ammonia reaction gas streams were turned on. After heating to 1310°C, the temperature was kept constant for 200 minutes. After the synthesis is over, the studio is cooled to 40-50°C and then ventilated with air and openings.

[0083] After synthesis, 280 mg of snow-white fluffy powder was obtained. According to scanning electron mic...

Embodiment 2

[0089] A powder mixture with a mass of 11.76 g was put into the crucible of the reactor, the powder mixture containing 78 wt.% boric acid, 4 wt.% magnesium oxide and 18 wt.% amorphous boron. After the reactor was preliminarily removed from impurities, it was filled with an inert gas, heated to the working temperature and delivered transport gas and reaction gas (method in Example 1), the working temperature was 1190° C. and kept constant for 320 minutes. After synthesis, 345 mg of snow-white fluffy powder was obtained, which was an aggregate of boron nitride nanoparticles with a diameter of 70-100 nm.

[0090] The boron nitride aggregates were sonicated for 30 min at 80 W in distilled water. The concentration of boron nitride nanoparticles was 2 mg / ml. Particle size distribution studies showed that the amount of nanoparticles and their aggregates with a size greater than 250 nm was less than 1%.

[0091] In the 5 mg / ml doxorubicin aqueous solution, the boron nitride nanopart...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com