Bi-tellurium-containing biodegradable polymer and preparation method thereof

A technology for degrading polymers and biology, which is applied in the direction of fermentation, etc., can solve the problems of limiting the application of ditellurium compounds, few polymers containing ditellurium, and non-biodegradable, etc., to achieve excellent light environment response performance, high yield, and by-products little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

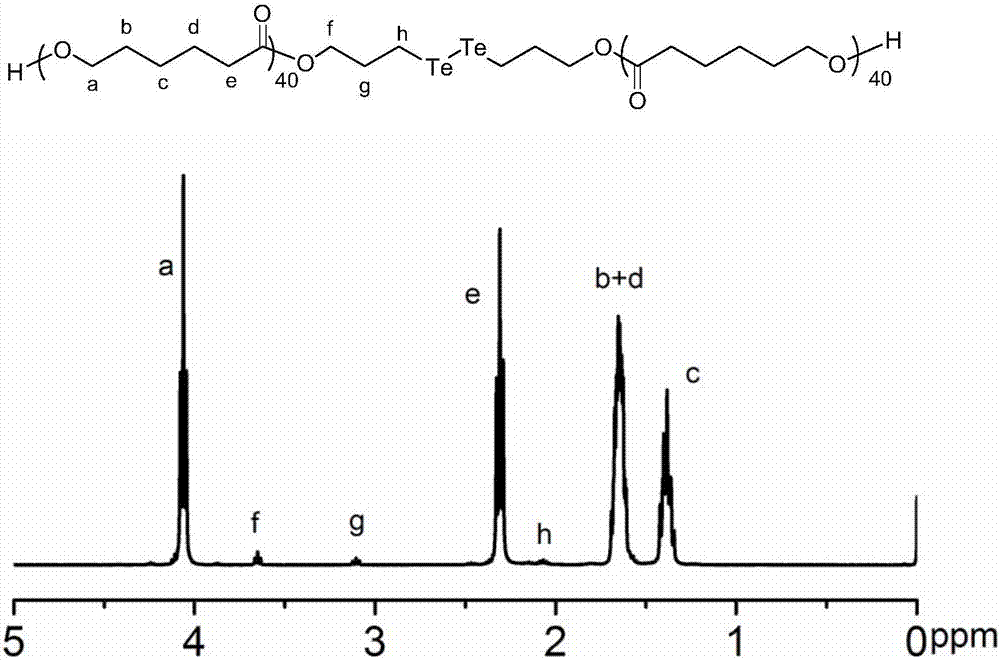

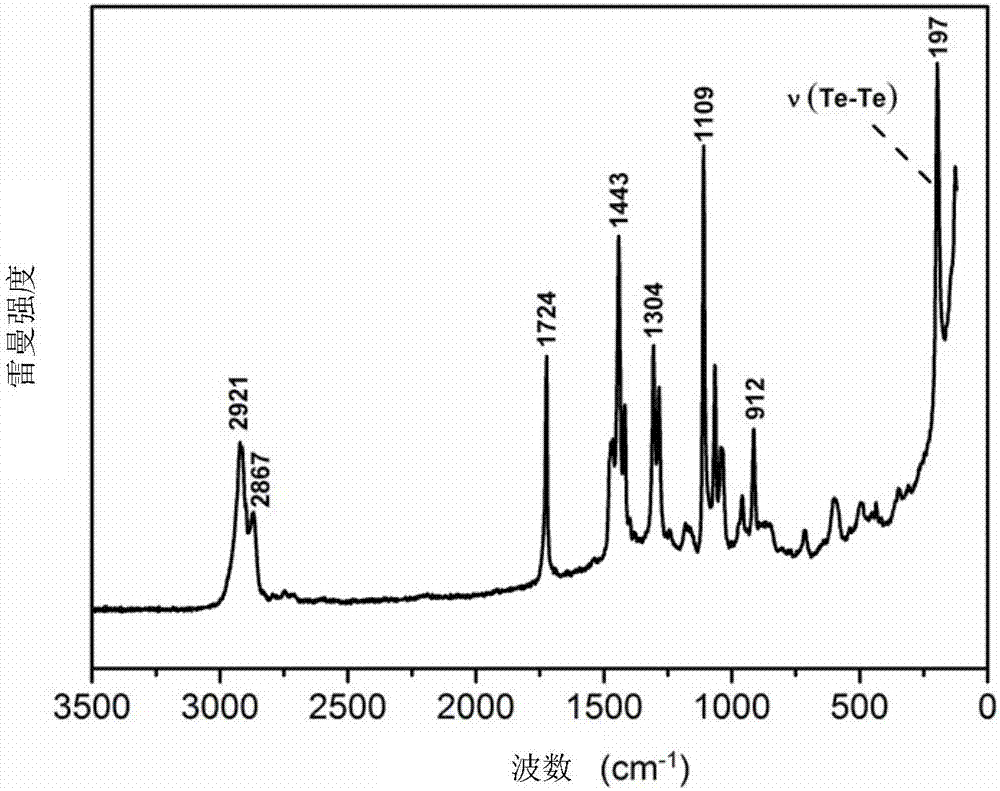

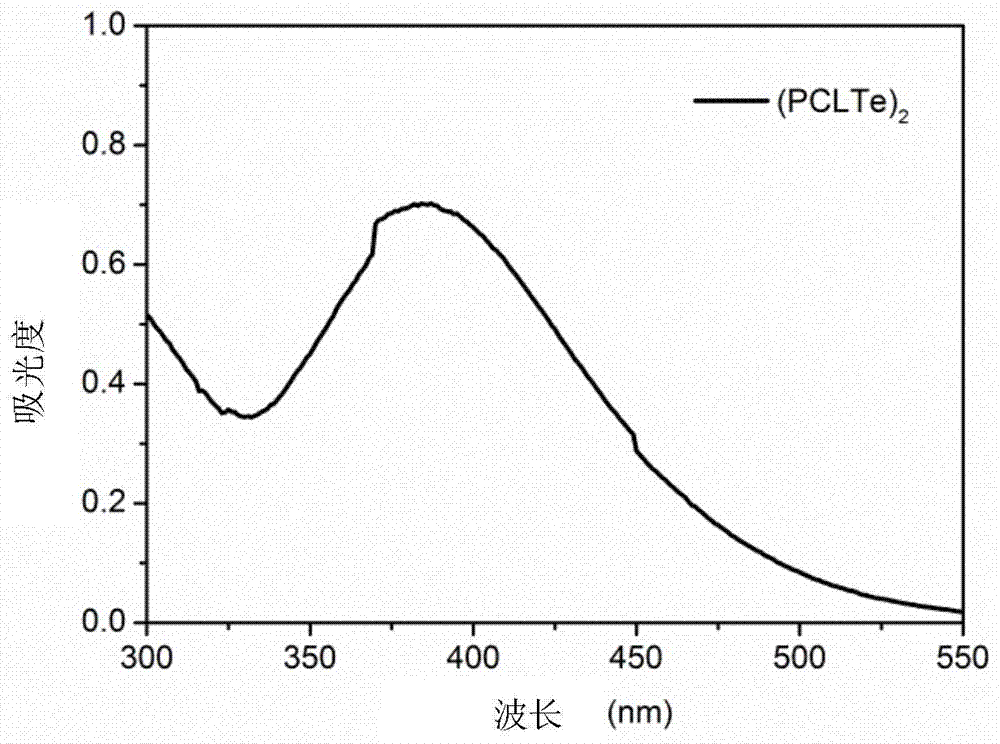

[0031] Embodiment 1 contains ditelluric polycaprolactone (PCLTe) 2 (I-1a)

[0032] Synthesis of 2,2'-Ditelluridedipropanol (II-1)

[0033]

[0034] Weigh (2.2698g, 60mmol) sodium borohydride and deionized water (150mL) into a 500mL reaction bulb and stir until the sodium borohydride is completely dissolved, then add tellurium powder (7.26g, 60mmol) and react at 70°C for 30min, to get the magenta Na 2 Te 2 solution. Then, under nitrogen protection, bromopropanol (8.34 g, 60 mmol) in tetrahydrofuran (150 mL) was added, and reacted at 50° C. in the dark for 5 hours. After the reaction was completed, it was extracted with anaerobic dichloromethane, dried over anhydrous magnesium sulfate, and separated by column chromatography (eluent: dichloromethane: ethyl acetate = 1:2 (v / v)) to obtain a purple-red compound, That is, 2,2'-ditelluridedipropanol (II-1). 1 H NMR (400MHz, CDCl 3 )δ(ppm):3.72(4H,t,HOCH 2 ),3.19(4H,t,TeTeCH 2 ),2.00(4H,m,HOCH 2 CH 2 CH 2 TeTe) and 1.70(...

Embodiment 2

[0041] Embodiment 2 contains two tellurium polycarbonates (PTMCTe) 2 (I-1b)

[0042]

[0043] Add 2,2'-ditelluridedipropanol (0.372g, 1mmol), trimethylene carbonate (TMC) (4.08g, 40mmol) into a pre-baked eggplant-shaped reaction bottle, and vacuumize at 40°C A small amount of moisture was removed for 3 hours, then Novozymes lipase 435 (0.408 g) and anhydrous oxygen-free toluene (10 mL) were added under nitrogen protection, and the reaction was carried out at 60° C. for 24 hours. After the reaction was completed, the enzyme was removed by filtration, settled in glacial ether, and vacuum-dried to obtain the target product ditellurium-containing polycarbonate (I-1b), with a yield of 91%.

[0044] 1 H NMR (400MHz, CDCl 3 )δ(ppm) (such as Figure 4 shown): a (4.24), b (2.05), c (4.10), e (3.10), d (2.07).

[0045] 125 Te NMR (189MHz, CDCl 3 ) δ (ppm): 388.4.

Embodiment 3

[0046] Embodiment 3 contains ditelluric polycaprolactone (PCLTe) 2 (I-2a)

[0047] Synthesis of 2,2'-Ditelluridediethanol (II-2)

[0048]

[0049] Weigh sodium borohydride (2.2698g, 60mmol) and deionized water (150mL) into a 500mL reaction ball bottle and stir until sodium borohydride is completely dissolved, then add tellurium powder (7.26g, 60mmol) and react at 70°C for 30min , to obtain the purple-red Na 2 Te 2 solution. Then, under nitrogen protection, bromoethanol (7.49 g, 60 mmol) in tetrahydrofuran (150 mL) was added, and reacted at 50° C. in the dark for 6 hours. After the reaction was completed, it was extracted with anaerobic dichloromethane, dried over anhydrous magnesium sulfate, and separated by column chromatography (eluent was dichloromethane:ethyl acetate=1:1 (v / v)) to obtain a purple-red compound, That is, 2,2'-ditelluridediethanol. 1 HNMR (400MHz, CDCl 3 )δ(ppm):3.87(4H,t,HOCH 2 ),3.32 (4H,t,TeTeCH 2 ), and 2.11 (2H,s,HOCH 2 ). 13 C NMR (125MHz,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com