Enhanced in-situ chemical oxidation repairing technology of soil and underground water

An in-situ chemical oxidation and groundwater technology, applied in the restoration of polluted soil, chemical instruments and methods, water pollutants, etc. Area and other issues, to achieve the effect of simple and flexible design and operation, low-cost repair, and less secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A soil and groundwater enhanced in-situ chemical oxidation restoration process is carried out according to the following steps:

[0030] 1) Contaminated site measurement: According to the site survey technology, the depth and area of pollution, soil physical and chemical properties, and the type and concentration of pollutants are known; the depth and location of horizontal injection wells and the type and ratio of oxidizing agents are determined based on the above materials.

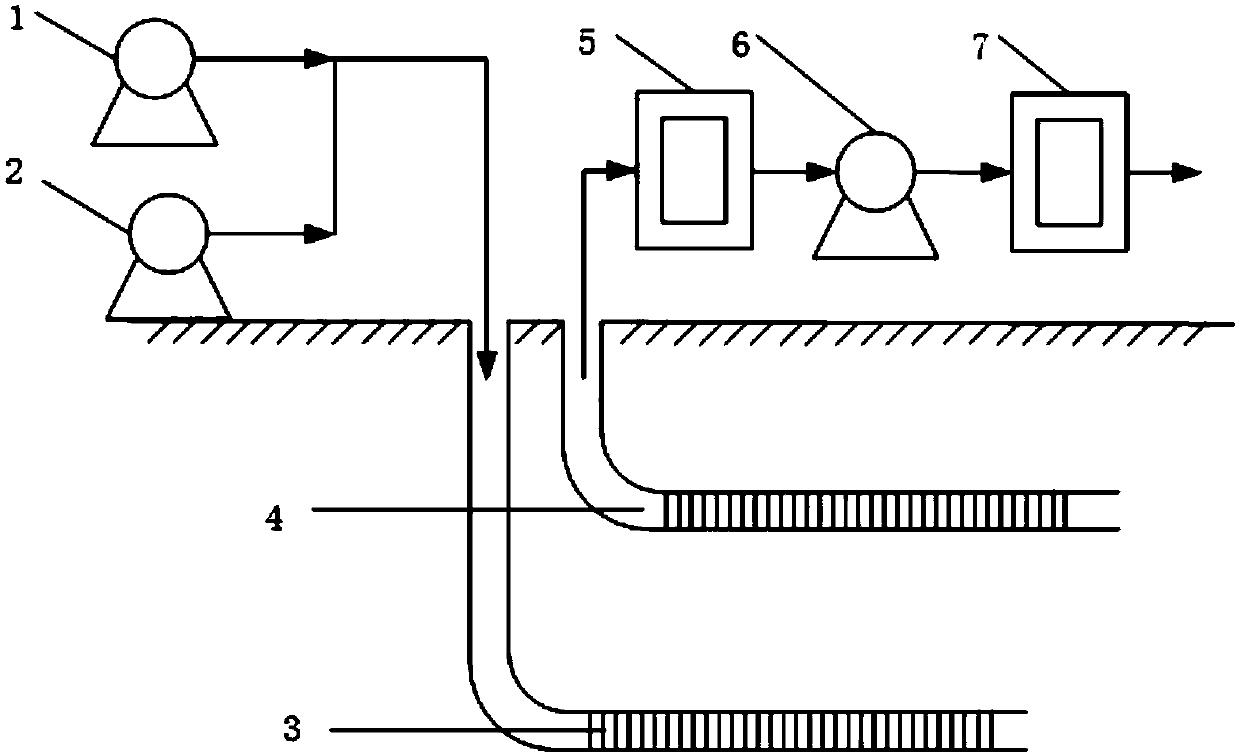

[0031] 2) Build repair equipment at the repair site: Build repair equipment according to the depth and position of the horizontal injection well determined in step 1), the repair equipment includes: dosing pump 1, gas injection pump 2, horizontal injection well 3, horizontal Extraction well 4, gas-liquid separator 5, extraction pump 6 and plasma purifier 7; the drug outlet of the dosing pump and the gas outlet of the gas injection pump are connected to the drug inlet of the horizontal drug injec...

Embodiment 2

[0043] Taking an industrial site as an example, it can be divided into four layers according to the age of formation: miscellaneous filling layer, silty clay layer, silt layer and silty clay layer. The site pollutants are mainly petroleum hydrocarbons, mainly concentrated in the upper silty clay layer and silt layer, and the pollution depth is 3.5m-9.5m.

[0044] First, build horizontal drug injection wells and horizontal extraction wells in and above the polluted area. The chemical reacts with the pollutants; after all the oxidizing agents are added, the air injection pump is turned on, and the air is injected into the contaminated part through the air injection pump to provide the oxygen required for the reaction; The agent is injected into the contaminated site to biodegrade the residual pollutants and reactants.

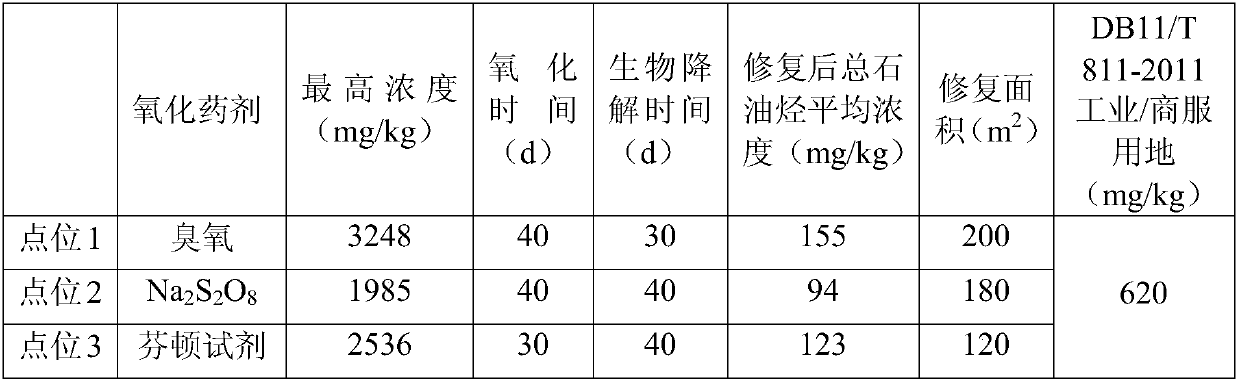

[0045] This embodiment includes 3 processing points, numbered respectively: point 1, point 2, and point 3. The concentration of total petroleum hydrocarbons (<...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com