Method for increasing total-component utilization rate of agricultural straw raw materials

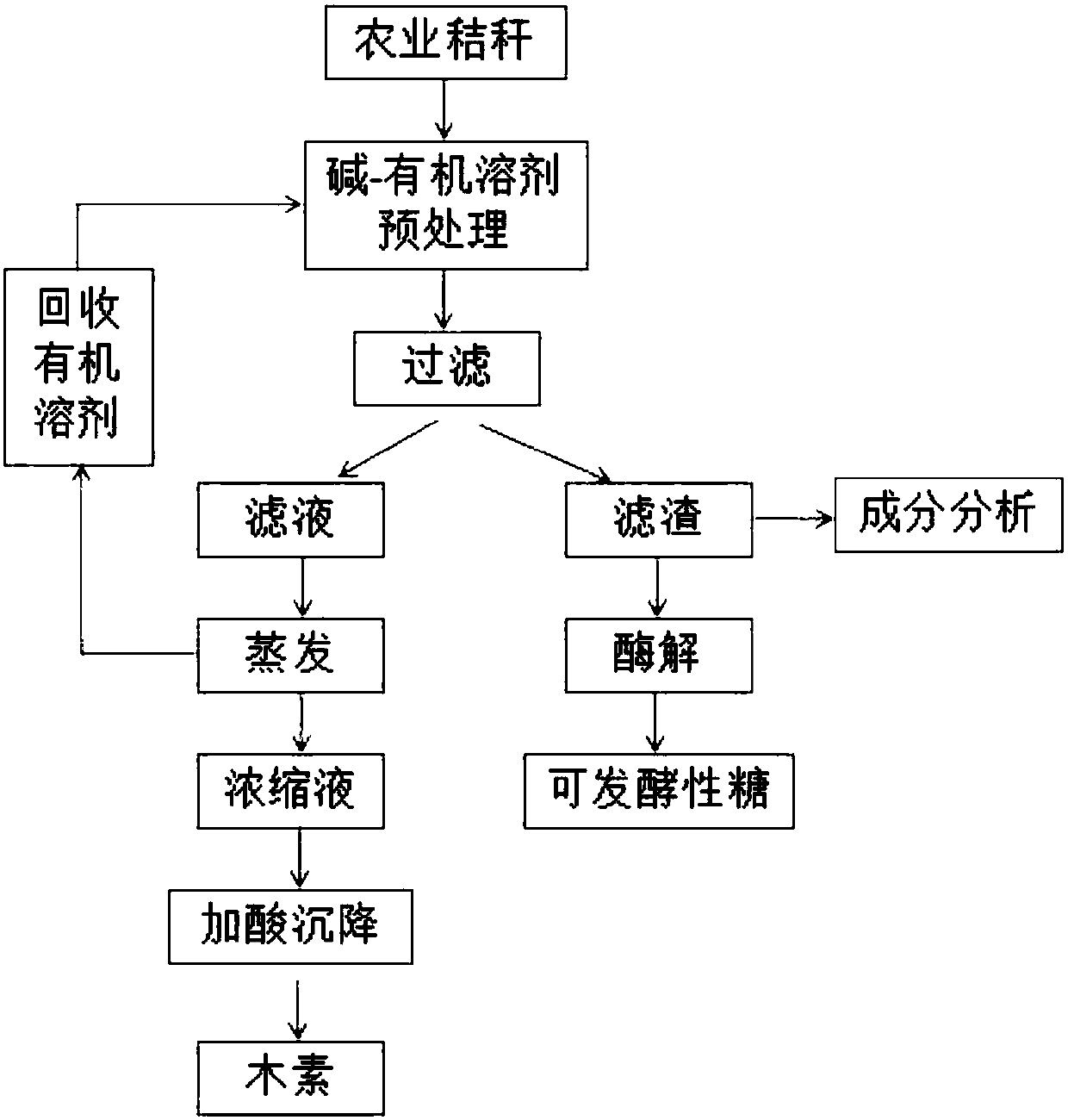

A technology with full components and high utilization rate, applied in the direction of fermentation, etc., can solve the problems of difficult cleaning of lignin and high reaction temperature, and achieve the effect of good washing effect, high reactivity and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The pretreatment and enzymolysis of different NaOH mass fractions of embodiment 1

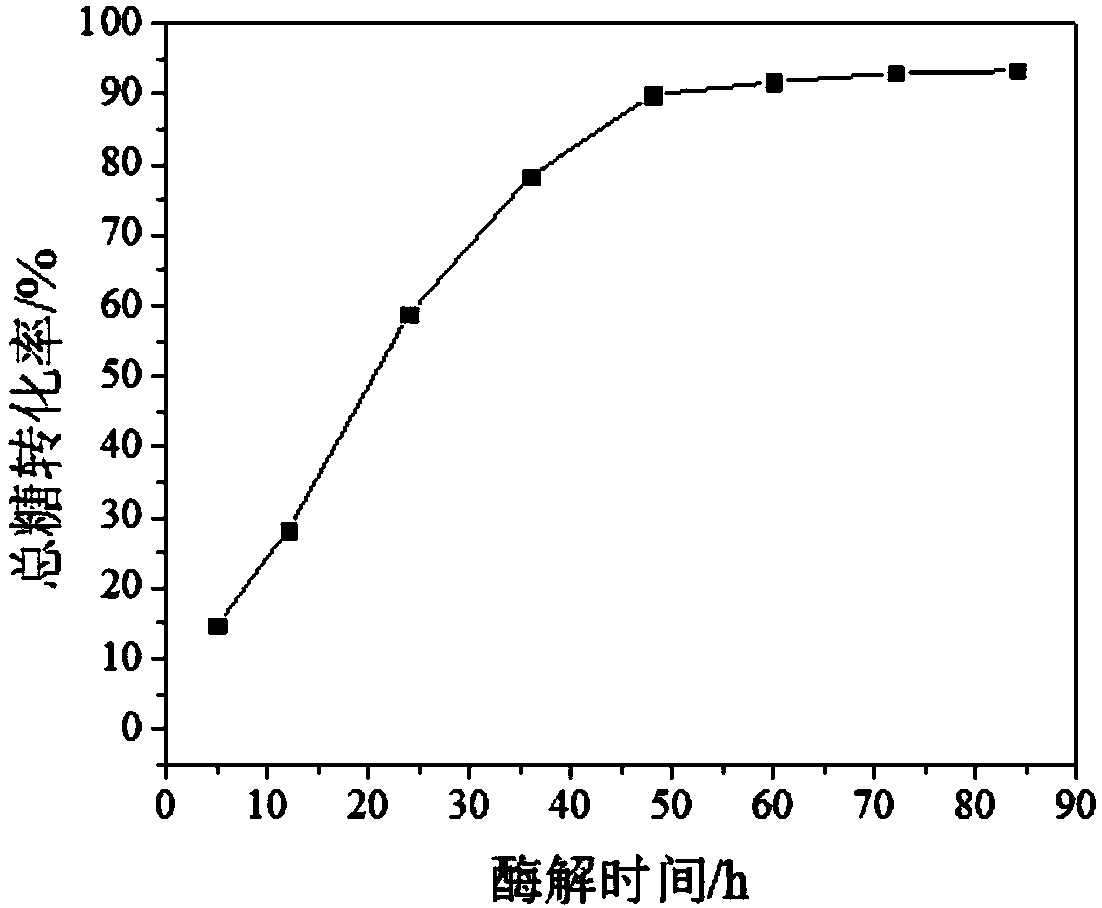

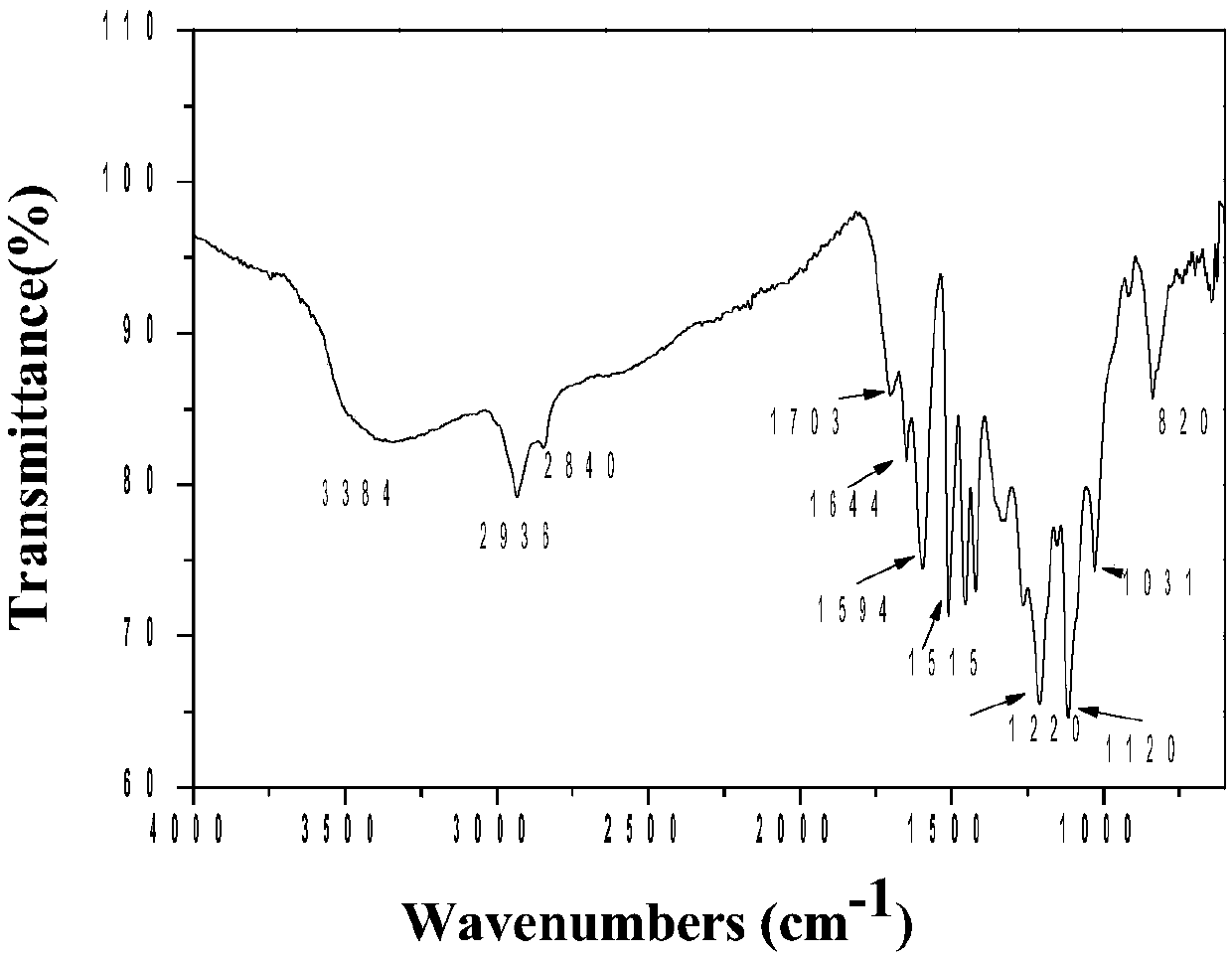

[0030]Wheat straw is selected as the raw material, cut into 3-5 cm grass slices manually or mechanically, washed with water and air-dried, crushed with a pulverizer, and sieved with a standard sieve to collect 40-80 mesh particles. Select sodium hydroxide as an additive, ethanol as an organic solvent, add a certain mass of NaOH to the ethanol solution with a volume fraction of 50%, and configure NaOH with a mass fraction of 0.2%, 1%, and 1.8% respectively. For the treatment agent, the solid-to-liquid ratio is 1:10g / ml, the reaction temperature is 130°C, the holding time is 3h, and the solid-liquid separation is carried out by vacuum filtration after the reaction is completed. The solid was washed with a large amount of ultrapure water to neutrality and then dried at 40°C. Calculate the yield and analyze the chemical composition of the material. Add acetic acid-sodium acetate buffer (pH...

Embodiment 2

[0037] The pretreatment of embodiment 2 different temperatures

[0038] Wheat straw is selected as the raw material, cut into 3-5 cm grass slices manually or mechanically, washed with water and air-dried, crushed with a pulverizer, and sieved with a standard sieve to collect 40-80 mesh particles. Select sodium hydroxide as additive, ethanol as organic solvent, configure sodium hydroxide mass fraction as 1%, ethanol volume fraction as sodium hydroxide-ethanol pretreatment agent of 50%, solid-liquid ratio 1: 10g / ml, reaction temperature respectively 90°C and 170°C, the holding time is 3h, after the reaction is completed, vacuum filtration is carried out for solid-liquid separation. The solid was washed with a large amount of ultrapure water to neutrality and then dried at 40°C. Calculate the yield and analyze the chemical composition of the material. Add acetic acid-sodium acetate buffer (pH=4.8) to the solid material to maintain a solid-liquid ratio of 1:40g / ml, add 30FPU / g c...

Embodiment 3

[0042] The pretreatment of embodiment 3 different types of alkaline additives

[0043] Wheat straw is selected as the raw material, cut into 3-5 cm grass slices manually or mechanically, washed with water and air-dried, crushed with a pulverizer, and sieved with a standard sieve to collect 40-80 mesh particles. Choose sodium hydroxide, potassium hydroxide and ammonia water as alkaline additives respectively, ethanol as organic solvent, add the alkali into the ethanol solution with a volume fraction of 50%, and configure sodium hydroxide and potassium hydroxide with a mass fraction of alkali of 1% respectively Alkaline ethanol pretreatment agent with ammonia water, the solid-liquid ratio is 1:10g / ml, the reaction temperature is 130°C, the holding time is 3h, and the solid-liquid separation is carried out by vacuum filtration after the reaction. The solid was washed with a large amount of ultrapure water to neutrality and then dried at 40°C. Calculate the yield and analyze the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com