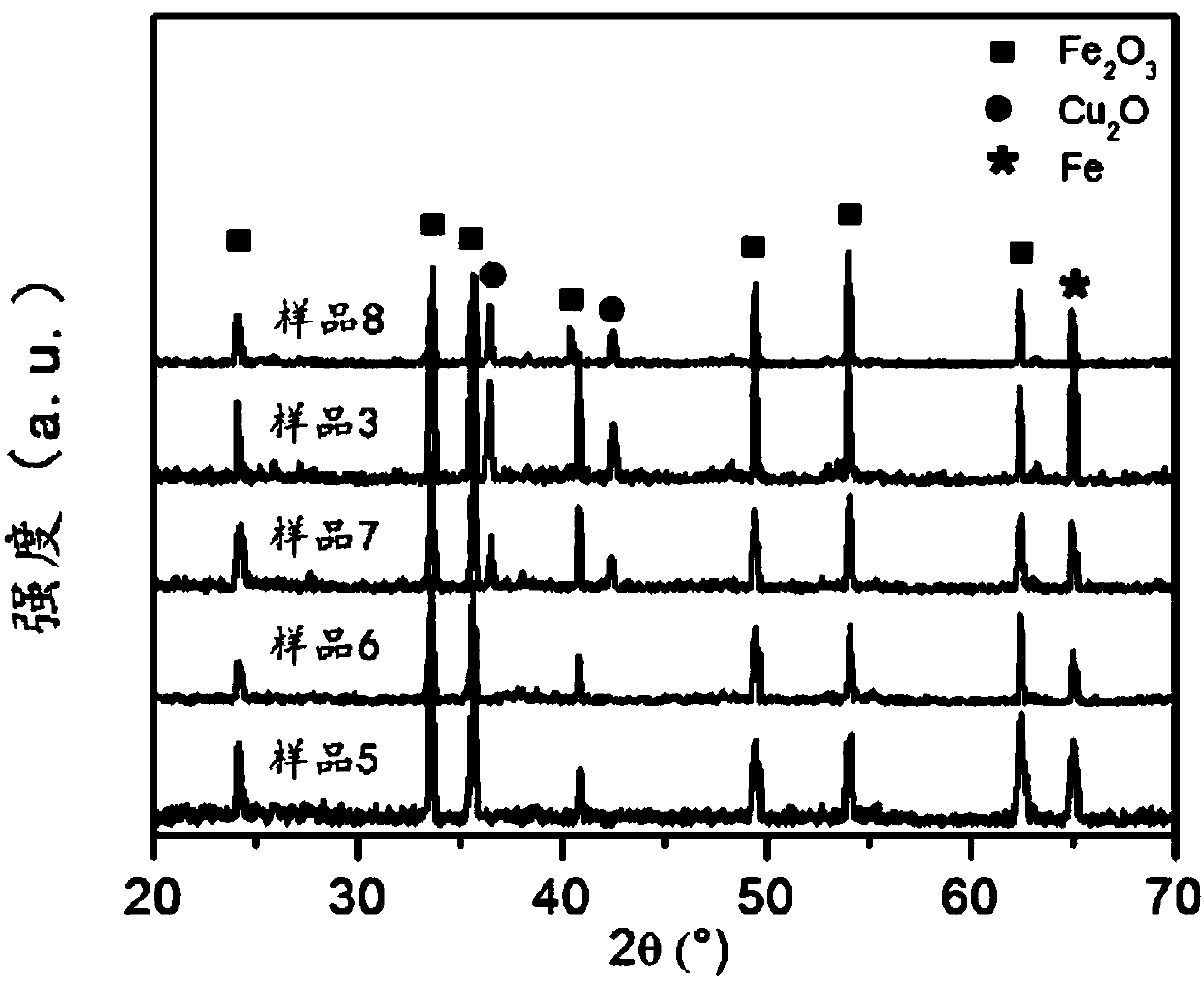

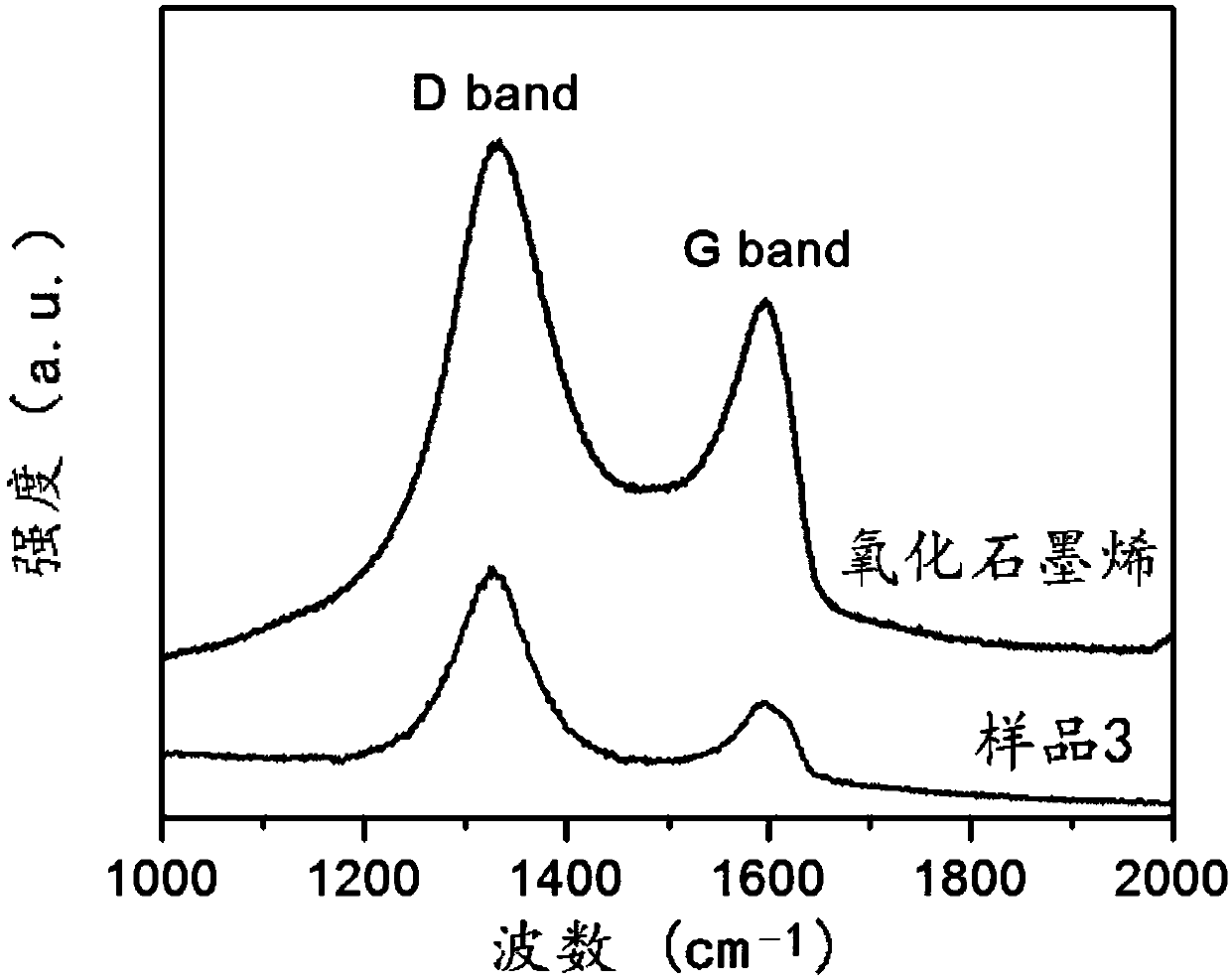

Z-type heterojunction Cu2O_graphene_alpha-Fe2O3 nanotube array photocatalyst and preparation thereof

A nanotube array, photocatalyst technology, applied in anodizing, electrodes, electrolytic coatings, etc., can solve problems such as hindering wide application, semiconductor oxidation of heterojunction photocatalytic materials, and reduction in reducing ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

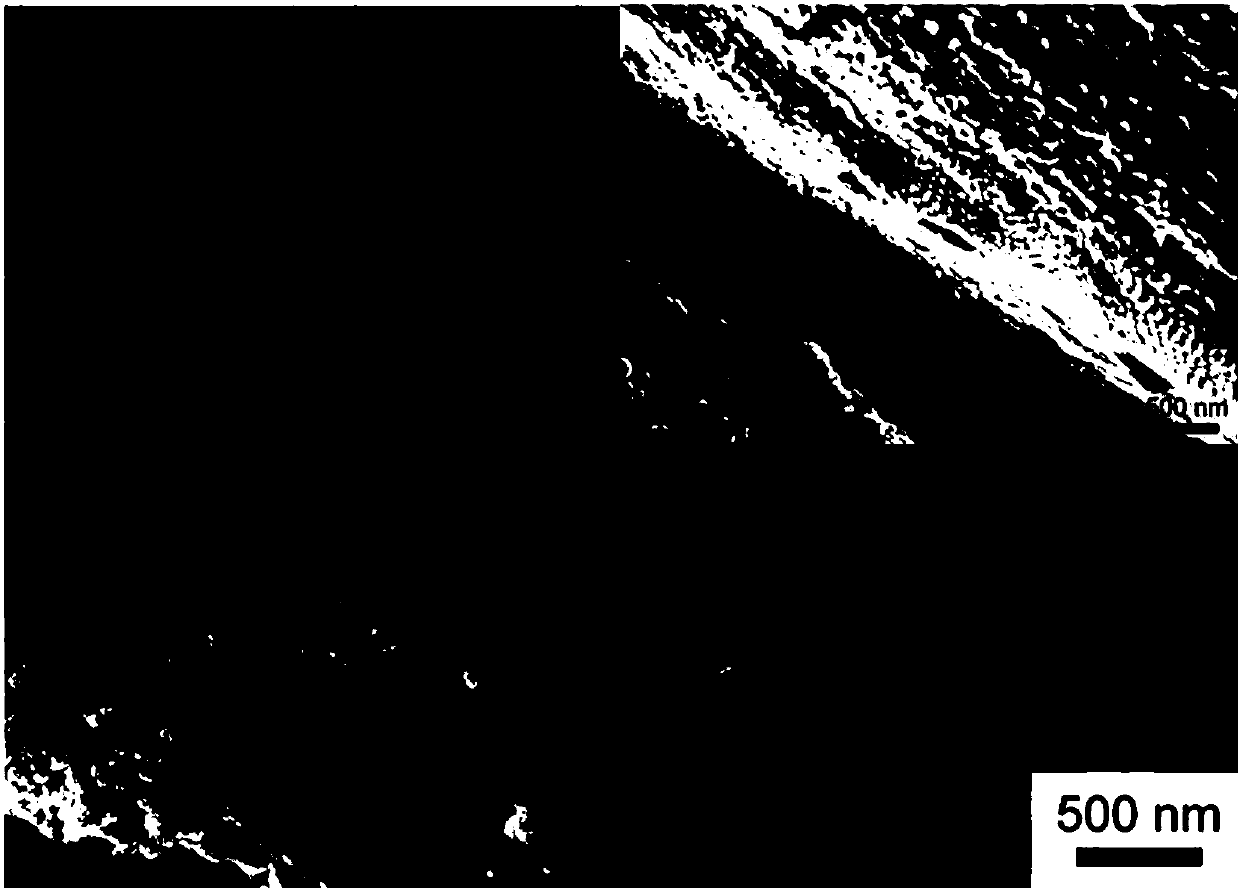

Embodiment 1

[0032] (1) A high-purity iron sheet (10 mm × 25 mm × 1.5 mm) polished with sandpaper was ultrasonically treated in absolute ethanol and distilled water for 10 min, and dried with nitrogen gas for later use. With pretreated iron sheet as anode, platinum sheet as cathode, 0.05wt% NH 4 F ethylene glycol solution (which contains 0.5% deionized water by volume fraction) is the electrolyte, at 30V, 10°C, oxidation reaction for 1min, then ultrasonic treatment in deionized water for 5min to remove the first anodic oxidation Nanoporous oxide layer; then use the iron sheet that has been oxidized once as the anode, and the platinum sheet as the cathode. In the same electrolyte, the second anodic oxidation reaction continues for the same time under the same oxidation conditions. After the oxidation reaction, the obtained iron sheet samples were rinsed with deionized water, dried with nitrogen, and placed in a muffle furnace under an oxygen atmosphere at 200°C, calcined at a constant tempe...

Embodiment 2

[0036] (1) A high-purity iron sheet (10 mm × 25 mm × 1.5 mm) polished with sandpaper was ultrasonically treated in absolute ethanol and distilled water for 10 min, and dried with nitrogen gas for later use. With pretreated iron sheet as anode, platinum sheet as cathode, 0.1wt% NH 4 F ethylene glycol solution (which contains 1% deionized water by volume fraction) is the electrolyte, at 40V, 15°C, oxidation reaction 2min, then ultrasonic treatment in deionized water for 5min to remove the first anodic oxidation formed Nanoporous oxide layer; then use the iron sheet that has been oxidized once as the anode, and the platinum sheet as the cathode. In the same electrolyte, the second anodic oxidation reaction continues for the same time under the same oxidation conditions. After the oxidation reaction, the obtained iron sheet samples were rinsed with deionized water, dried with nitrogen, and placed in a muffle furnace under an oxygen atmosphere at 300°C, calcined at a constant tempe...

Embodiment 3

[0040] (1) A high-purity iron sheet (10 mm × 25 mm × 1.5 mm) polished with sandpaper was ultrasonically treated in absolute ethanol and distilled water for 10 min, and dried with nitrogen gas for later use. With pretreated iron sheet as anode, platinum sheet as cathode, 0.2wt% NH 4 F ethylene glycol solution (which contains 2% deionized water by volume fraction) is the electrolyte, at 50V, 20°C, oxidation reaction for 5min, then ultrasonic treatment in deionized water for 5min to remove the first anodic oxidation formed Nanoporous oxide layer; then use the iron sheet that has been oxidized once as the anode, and the platinum sheet as the cathode. In the same electrolyte, the second anodic oxidation reaction continues for the same time under the same oxidation conditions. After the oxidation reaction, the obtained iron sheet samples were rinsed with deionized water, dried with nitrogen, and placed in a muffle furnace under an oxygen atmosphere at 400°C, calcined at a constant t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com