Organic field effect transistor-based ammonia gas sensor and preparation method therefor

An ammonia sensor and organic field technology, applied in the field of sensors, can solve the problems of high manpower and material consumption and high cost, and achieve the effects of saving manpower and material resources, no need to extract, and improving response rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A method for preparing an organic field effect transistor ammonia sensor, comprising the following steps:

[0036] ① Clean the substrate layer with detergent, acetone solution, deionized water and isopropanol solution, and dry it with nitrogen after cleaning;

[0037] ②Preparing a gate electrode on the surface of the substrate layer;

[0038] ③ Prepare a dielectric layer on the gate electrode;

[0039] ④ Ultrasonic mixing of egg white protein and soluble organic semiconductor material in proportion; using the mixed solution to prepare an organic semiconductor layer on the dielectric layer;

[0040] ⑤ Prepare source and drain electrodes on the organic semiconductor layer.

[0041] In the above step ③, the dielectric layer is prepared by one of the methods of spin coating, roll coating, drop film, embossing, printing or spray coating.

[0042] In the above step ④, the organic semiconductor layer is prepared by one of the methods of dynamic spin coating, roller coating,...

Embodiment 1

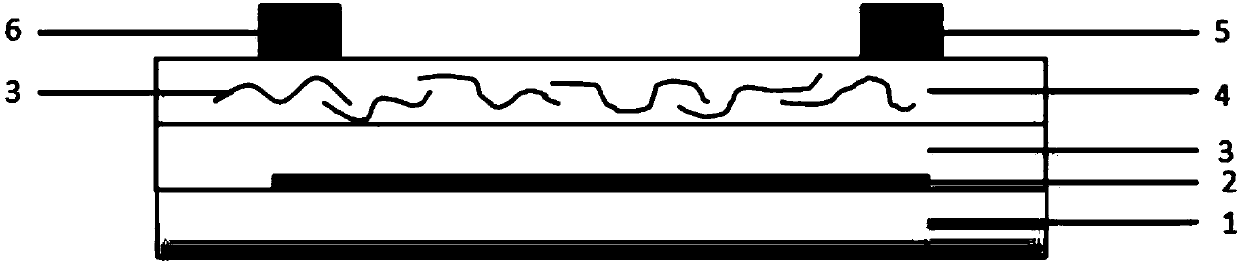

[0045] Such as figure 1 The bottom gate top contact structure is shown, the gate electrode 2, the source electrode 5 and the drain electrode 6 are all silver nanowires, the dielectric layer 3 is made of egg white protein, and the thickness is 200nm; the organic semiconductor layer 4 is poly 3-hexylthiophene (P3HT) is mixed with egg white protein (10% by mass), and the thickness is 30nm. A field effect transistor gas sensor with high sensitivity and high stability can be realized by using the structure.

[0046] ① Clean the substrate layer with detergent, acetone solution, deionized water and isopropanol solution, and dry it with nitrogen after cleaning;

[0047] ② Preparation of gate electrodes on the surface of the substrate layer;

[0048] ③Preparing a dielectric layer on the gate electrode;

[0049]④ Ultrasonic mixing of egg white protein and soluble organic semiconductor material in proportion. Use the mixed solution on the dielectric layer

[0050] Prepare an organic...

Embodiment 2

[0053] Such as figure 1 The bottom gate top contact structure is shown, the gate electrode, source electrode and drain electrode are all copper nanowires, the dielectric layer is made of duck egg white protein, and the thickness is 500nm; the organic semiconductor layer is Tips-pentacene (Tips-pentacene) It is formed by mixing with egg white protein (accounting for 15% by mass), and the thickness is 30nm. A field effect transistor gas sensor with high sensitivity and long life can be realized by using the structure.

[0054] ① Clean the substrate layer with detergent, acetone solution, deionized water and isopropanol solution, and dry it with nitrogen after cleaning;

[0055] ②Preparing a gate electrode on the surface of the substrate layer;

[0056] ③Preparing a dielectric layer on the gate electrode;

[0057] ④ Ultrasonic mixing of egg white protein and soluble organic semiconductor material in proportion. Using the mixed solution to prepare an organic semiconductor laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com