Core-shell type magnetic fluorescent sensing microsphere for hexavalent chromium anion imprints

A fluorescent sensing and anion technology, applied in alkali metal oxides/hydroxides, inorganic chemistry, water/sludge/sewage treatment, etc., can solve problems such as cumbersome methods and increased environmental burdens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

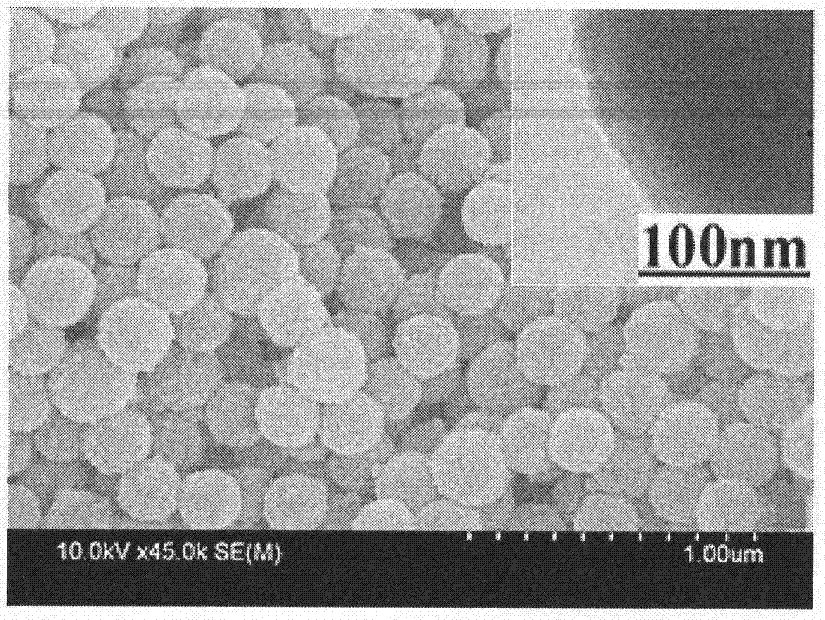

[0029] (1) Under the action of ultrasound, completely dissolve 2.7g of ferric chloride hexahydrate in 80mL of ethylene glycol, then add 0.5g of sodium citrate and 3.6g of anhydrous sodium acetate for mixing, and stir rapidly for 1-2 hours. Put the mixed solution into a polytetrafluoroethylene stainless steel hydrothermal reaction kettle, move the hydrothermal reaction kettle to an oven at 200 ° C for 12 hours, take out the reaction kettle after the reaction is completed and cool it to room temperature, and use a magnet to absorb the obtained Fe 3 o 4 The nanoparticles are separated, washed with absolute ethanol for 3 to 4 times, and then put into a vacuum drying oven at 40° C. to dry to constant weight.

[0030] (2) Add 140mL absolute ethanol and 3mL ammonia water with a mass fraction of 28% to a 250mL three-necked bottle, and then add 0.30g Fe 3 o 4 Nanoparticles were ultrasonically dispersed for 1 h, and then a mixture of ethanol and tetraethyl orthosilicate (TEOS) (10 mL ...

Embodiment 2

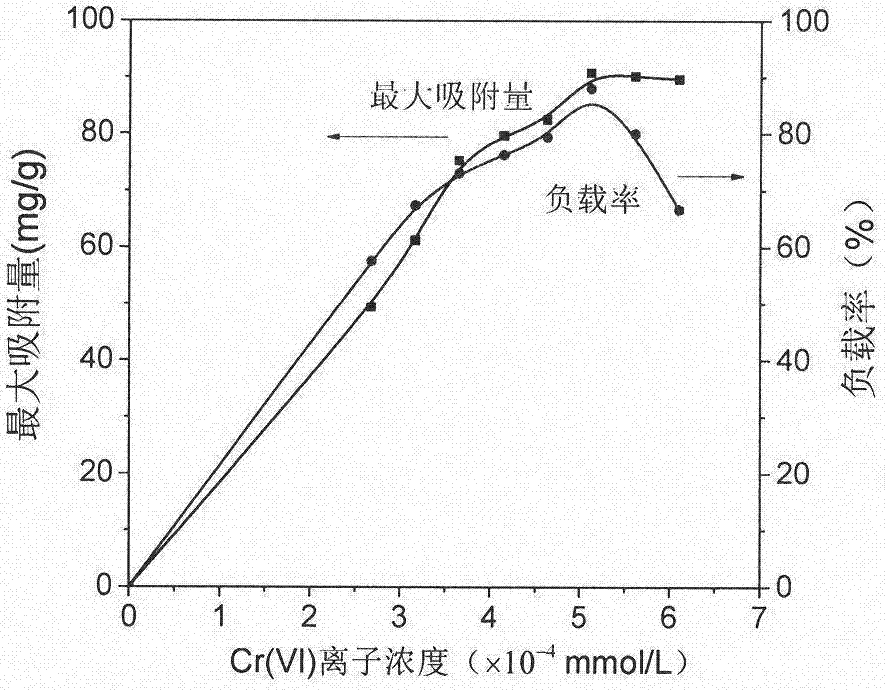

[0034] Get the K of 0.5mL 0.268mmol / L of embodiment 1 2 Cr 2 o 7 , 0.1g double bond modified Fe 3 o 4 Particles, add 40mL of acetonitrile as a solvent, after ultrasonic dispersion, add 1mmol of NIPAM as an adsorption monomer, 0.5mmol of NVC as a fluorescent monomer, 2mmol of ethylene glycol dimethacrylate (EGDMA) as a cross-linking agent and 0.02 g AIBN was used as an initiator, and the fluorescence enhancement rate of the obtained microspheres was 42.5% after distillation precipitation polymerization and removal of hexavalent chromium. Using the resulting microspheres for different concentrations of K 2 Cr 2 o 7 aqueous solution for adsorption, the results show that when K 2 Cr 2 o 7 When the concentration is 0.268mmol / L, it reaches its maximum adsorption capacity of 73.51mg / g, the highest adsorption efficiency is 68.28%, and then increases K 2 Cr 2 o 7 concentration, the maximum adsorption capacity remained unchanged, and the maximum adsorption efficiency gradual...

Embodiment 3

[0036] Get the K of 0.5mL 0.313mmol / L of embodiment 1 2 Cr 2 o 7 , 0.1 g double bond modified Fe 3 o 4 Particles, add 40mL of acetonitrile as solvent, after ultrasonic dispersion, add 1mmol of NIPAM as adsorption monomer, 0.5mmol of NVC as fluorescent monomer, 1.6mmol of DVB as cross-linking agent and 0.015g of AIBN as initiator, and precipitate by distillation After polymerization and removal of hexavalent chromium, the fluorescence enhancement rate of the obtained microspheres was 48.65%. Using the resulting microspheres for different concentrations of K 2 Cr 2 o 7 aqueous solution for adsorption, the results show that when K 2 Cr 2 o 7 When the concentration was 0.313mmol / L, it reached its maximum adsorption capacity of 61.24mg / g, and the highest adsorption efficiency was 52.38%, and then increased K 2 Cr 2 o 7 concentration, the maximum adsorption capacity remained unchanged, and the maximum adsorption efficiency gradually decreased.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com