Method for analyzing caprylic/capric triglyceride in essence by utilizing gas chromatography-mass spectrometry separation

A caprylic capric acid glyceride and gas chromatography technology, which is applied in the field of gas chromatography-mass spectrometry separation and analysis of caprylic capric acid glyceride in essence, can solve the problem of difficult aroma substances and caprylic capric acid glyceride analysis results, and the influence of flavor components , complex component analysis and other issues, to achieve the effect of improving the peak shape of the chromatographic peak, increasing the resolution, and simplifying the processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

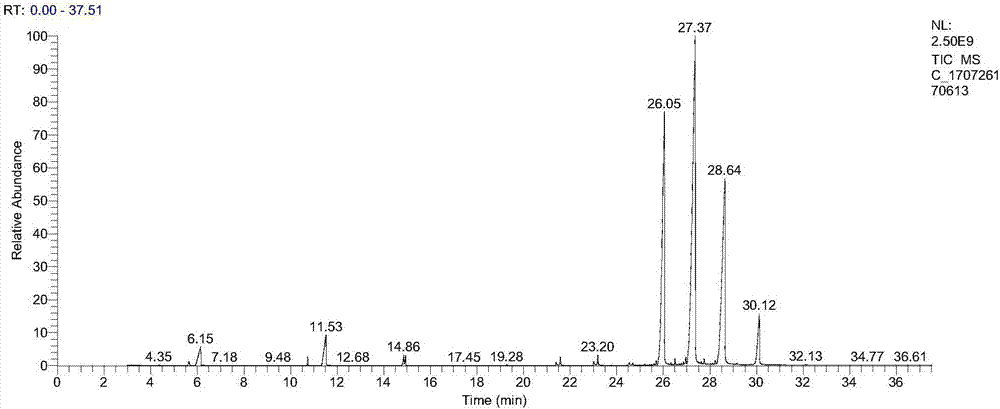

[0021] Example 1, a method for separating and analyzing caprylic acid glycerides in essence by gas chromatography-mass spectrometry, which specifically analyzes caprylic capric acid glycerides in coffee flavors, and the analysis steps are as follows:

[0022] (1) Sample pretreatment: Take 1g of coffee flavor sample containing caprylic acid glyceride and place it in a conical flask, add 10mL of dichloromethane added with phenylethyl acetate internal standard, and shake it on the shaker at a speed of 90r / min Shake for 20min;

[0023] (2) Oscillation completes, packs into chromatographic vial after filtering with 0.45 micron needle type microporous membrane, sends into gas chromatography-mass spectrometry to analyze, and analysis condition is as follows:

[0024] Chromatographic conditions: chromatographic column is HP-5MS, 30m×0.25μm×0.25mm capillary column; split injection, split ratio is 1:10; carrier gas is high-purity helium, flow rate is 1.0mL / min; injection volume: 1μL ;P...

Embodiment 2

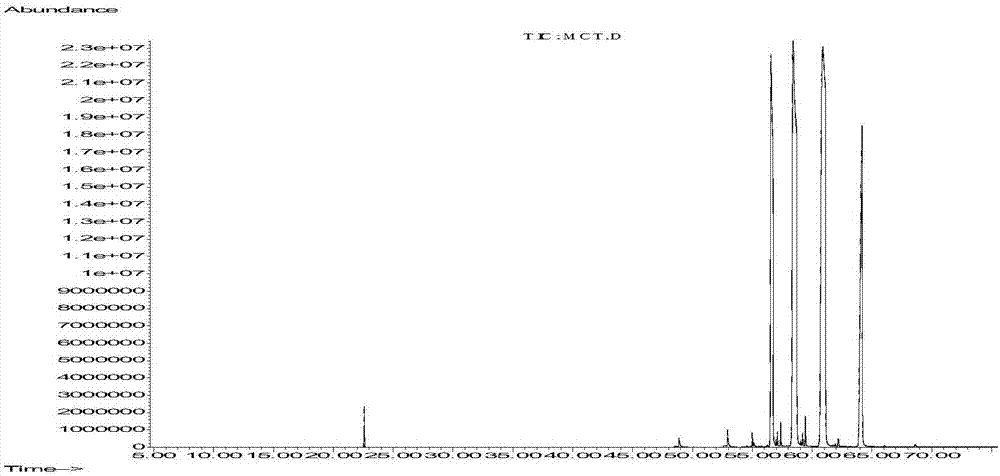

[0031] Embodiment 2, a method for separating and analyzing caprylic-capric glycerides in peppermint essence by gas chromatography-mass spectrometry, which specifically analyzes caprylic-capric glycerides in peppermint essences, and the analysis steps are as follows:

[0032] (1) Sample pretreatment: take 1g of the peppermint flavor sample containing caprylic acid glyceride and place it in a conical flask, add 50mL of dichloromethane added with phenylethyl propionate internal standard, and shake it on the shaker at 120r / min Speed oscillation for 15 minutes;

[0033] (2) Oscillation completes, packs into chromatographic vial after filtering with 0.45 micron needle type microporous membrane, sends into gas chromatography-mass spectrometry to analyze, and analysis condition is as follows:

[0034] Chromatographic conditions: HP-5MS column, 50m×0.25μm×0.25mm capillary column; split injection, split ratio 1:20; carrier gas is high-purity helium, flow rate 1.0mL / min; programmed tem...

Embodiment 3

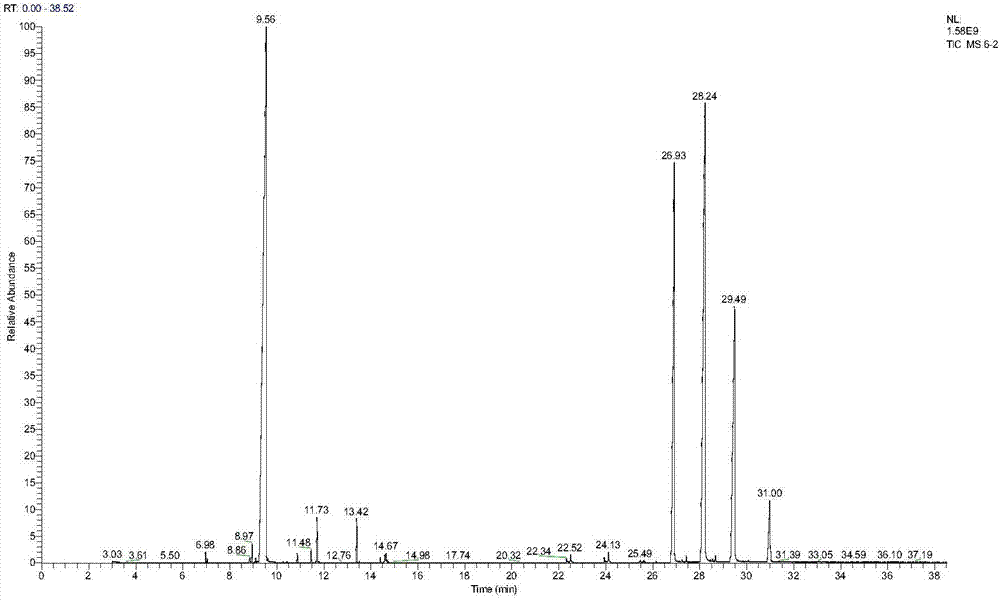

[0040] Embodiment 3, a method for separating and analyzing caprylic acid glyceride in essence by gas chromatography-mass spectrometry, which specifically analyzes caprylic capric acid glyceride in lemon essence, and the analysis steps are as follows:

[0041] (1) Sample pretreatment: take 0.5g of lemon essence sample and place it in a conical flask, add 10mL of dichloromethane added with phenylethyl acetate as an internal standard, and oscillate on an oscillator at a speed of 100r / min for 20min;

[0042] (2) Oscillation completes, packs into chromatographic vial after filtering with 0.45 micron needle type microporous membrane, sends into gas chromatography-mass spectrometry to analyze, and analysis condition is as follows:

[0043] Chromatographic conditions: chromatographic column is HP-5MS, 30m×0.25μm×0.25mm capillary column; split injection, split ratio is 1:10; carrier gas is high-purity helium, flow rate 1.0mL / min; programmed temperature: initial temperature 80°C; from 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com