High-strength ganged brick and preparation method thereof

A clear-water brick and high-strength technology, applied in the field of building materials, can solve the problems of uneven surface, low strength and high brittleness of clear-water bricks, and achieve the effects of simple preparation method, low equipment requirements and high flexural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

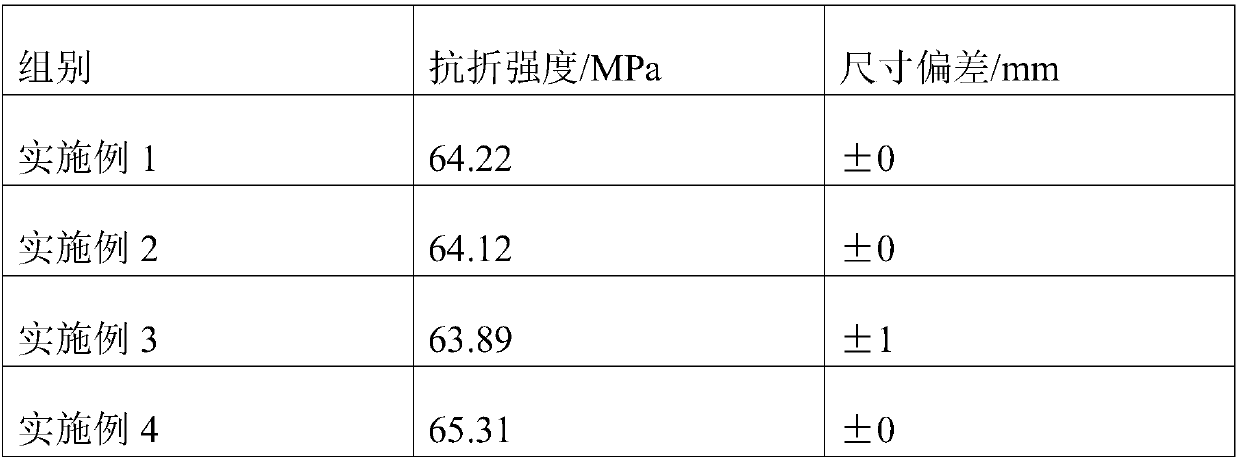

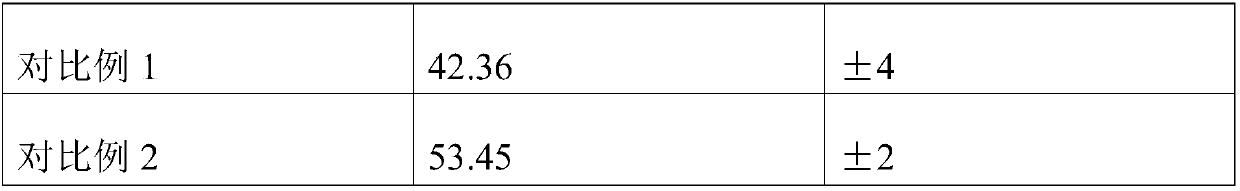

Examples

Embodiment 1

[0022] A high-strength clean-faced brick, which is mainly made of the following raw materials in terms of weight percentage: 14% cement, 70.4% stone powder (artificial sand), 0.05% colored blank, 14.8% fly ash, 0.05% water reducer and modified Agent 0.7%.

[0023] In terms of percentage by weight, the raw materials of the modifier include: 8% triisopropanolamine, 5% ferrous sulfate, 8% wood calcium, 10% sodium metaaluminate, 14% rosin, sodium fatty acid methyl ester sulfonate 2%, sodium fluorosilicate 14%, Glauber's salt 20%, acrylamide 4% and potassium hydrogen tartrate 15%.

[0024] The water reducing agent is acetone, alachlor, polycyclic aromatic hydrocarbon sulfonate formaldehyde condensate and porous calcium phosphate, and the mixing mass ratio is 1:1:1:1.

[0025] The colored blank includes iron oxide black.

[0026] A kind of preparation method of high-strength clear water brick, comprises the following steps:

Embodiment 2

[0031] A high-strength clean-faced brick, which is mainly made of the following raw materials in terms of weight percentage: 5% cement, 84% stone powder (artificial sand), 0.1% colored blank, 10% fly ash, 0.01% water reducer and modified Agent 0.89%.

[0032] In terms of percentage by weight, the raw materials of the modifier include: 6% of triisopropanolamine, 7% of ferrous sulfate, 12% of wood calcium, 6% of sodium metaaluminate, 16% of rosin, sodium fatty acid methyl ester sulfonate 1%, sodium fluorosilicate 7%, Glauber's salt 23%, acrylamide 5% and potassium hydrogen tartrate 17%.

[0033] The water reducer is a mixture of sodium sulfite and polycyclic aromatic hydrocarbon sulfonate formaldehyde condensate, and the mixing mass ratio is 1:1:1.

[0034] The colored blank includes iron oxide red.

[0035] A kind of preparation method of high-strength clear water brick, comprises the following steps:

[0036] (1) Mix and grind stone powder and fly ash into 100-200 mesh powd...

Embodiment 3

[0040] A high-strength clean-faced brick, which is mainly made of the following raw materials in terms of weight percentage: 20% cement, 58.89% stone powder (artificial sand), 0.01% colored blank, 20% fly ash, 0.1% water reducer and modified agent 1%.

[0041] In terms of percentage by weight, the raw materials of the modifier include: 6% of triisopropanolamine, 1% of ferrous sulfate, 8% of wood calcium, 11% of sodium metaaluminate, 9% of rosin, sodium fatty acid methyl ester sulfonate 3%, sodium fluorosilicate 20%, Glauber's salt 23%, acrylamide 2% and potassium hydrogen tartrate 17%.

[0042] The water reducer is a mixture of acetone and sodium sulfite in a mass ratio of 1:1.

[0043] The colored blank includes iron oxide yellow.

[0044] A kind of preparation method of high-strength clear water brick, comprises the following steps:

[0045] (1) Mix and grind stone powder and fly ash into 100-200 mesh powder, and then mix with cement, water reducer and modifier with water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com