Roxburgh rose fruit capsules and preparation method thereof

A roxburghii and capsule technology, which is applied in the field of roxburghii capsules and its preparation, can solve the problems of difficulty in reducing acid, harming the human body, single product, etc., and achieve the effect of accelerating nutrient absorption and decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

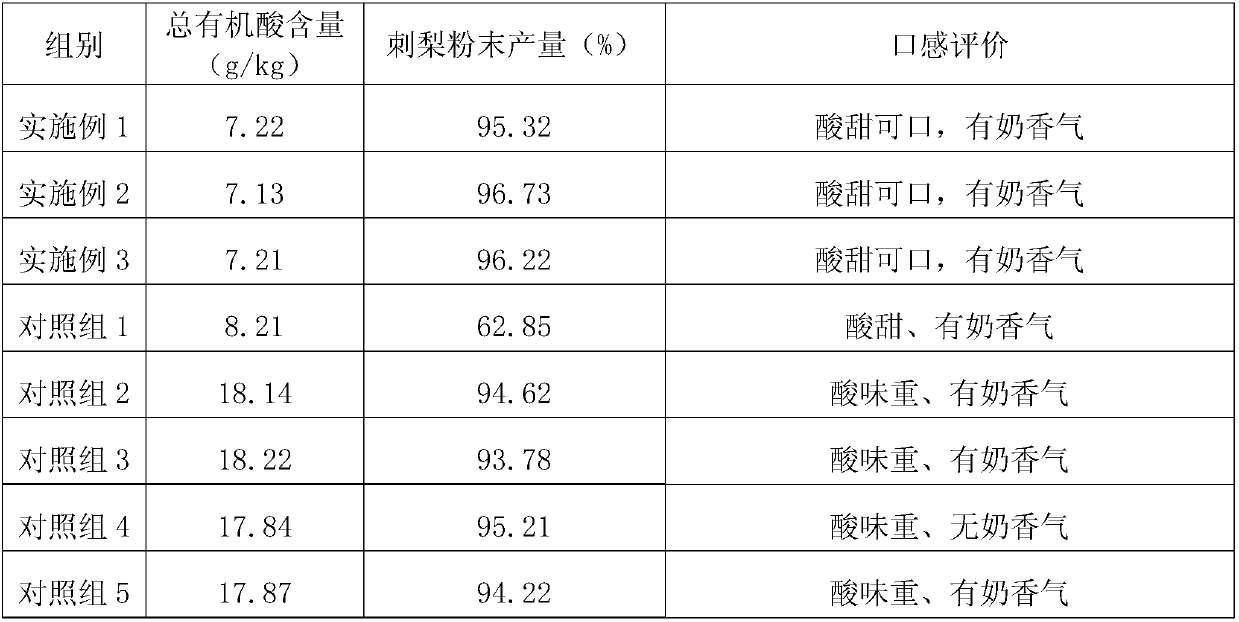

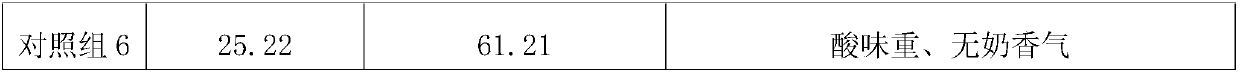

Examples

Embodiment 1

[0026] A roxburghii capsule, comprising an inner filling and a hollow capsule shell;

[0027] Wherein, the inner filling is made from the following raw materials by weight: 50 parts of prickly pear juice, 12 parts of yogurt, 1 part of pectinase, 13 parts of okra extract and 5 parts of acid reducer;

[0028] Wherein, the hollow capsule shell is made from the following raw materials in parts by weight: 30 parts of sodium alginate, 20 parts of aloe polysaccharide and 20 parts of agar powder.

[0029] The above-mentioned acid reducing agent is the extract of Cyclocarya paliurus.

[0030] The extraction method of the Cyclocarya paliurus extract in this example is as follows: after crushing the fresh Cyclocarya paliurus, add the same mass portion of ice water at a temperature of -1°C, let it stand for 30 minutes, and put it into an ultrasonic extractor for ultrasonication. Extraction, the extraction time is 4h, the extraction power is 900w, and then continue to add the same mass pa...

Embodiment 2

[0044] A roxburghii capsule, comprising an inner filling and a hollow capsule shell;

[0045] Wherein, the inner filling is made of the following raw materials by weight: 60 parts of prickly pear juice, 17 parts of yogurt, 5 parts of pectinase, 17 parts of okra extract and 10 parts of acid reducer;

[0046] Wherein, the hollow capsule shell is made from the following raw materials in parts by weight: 40 parts of sodium alginate, 30 parts of aloe polysaccharide and 30 parts of agar powder.

[0047] The above-mentioned acid reducing agent is the extract of Cyclocarya paliurus.

[0048] The extraction method of the Cyclocarya paliurus extract in this example is as follows: after crushing the fresh Cyclocarya paliurus, add the same mass portion of ice water at a temperature of -1°C, let it stand for 30 minutes, and put it into an ultrasonic extractor for ultrasonication. Extraction, the extraction time is 4h, the extraction power is 900w, and then continue to add the same mass pa...

Embodiment 3

[0062] A roxburghii capsule, comprising an inner filling and a hollow capsule shell;

[0063] Wherein, the inner filling is made from the following raw materials in parts by weight: 55 parts of prickly pear juice, 15 parts of yogurt, 3 parts of pectinase, 15 parts of okra extract and 7 parts of acid reducer;

[0064] Wherein, the hollow capsule shell is made from the following raw materials in parts by weight: 35 parts of sodium alginate, 25 parts of aloe polysaccharide and 25 parts of agar powder.

[0065] The above-mentioned acid reducing agent is the extract of Cyclocarya paliurus.

[0066] The extraction method of the Cyclocarya paliurus extract in this example is as follows: after crushing the fresh Cyclocarya paliurus, add the same mass portion of ice water at a temperature of -1°C, let it stand for 30 minutes, and put it into an ultrasonic extractor for ultrasonication. Extraction, the extraction time is 4h, the extraction power is 900w, and then continue to add the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com