Refractory low-carbon magnesium carbon brick

A carbon-magnesia-carbon brick and refractory technology, which is applied in the field of refractory materials, can solve the problems of poor slag corrosion resistance and thermal shock resistance, etc., and achieve the improvement of slag corrosion resistance, internal density, and internal organizational structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

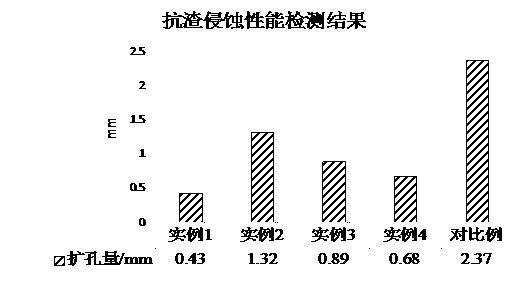

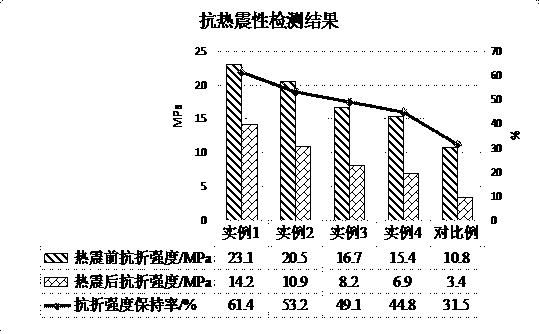

example 1

[0033]In parts by weight, 30 parts of particle diameters are added successively in the mixer to be 5mm fused magnesia, 30 parts of particle diameters are 2mm fused magnesia, 40 parts of particle diameter are 0.8mm fused magnesia, at a speed of Under the condition of 600r / min, stir and mix for 4 hours to obtain graded fused magnesia; mix rice husk and water according to the mass ratio of 1:15, stand and soak at room temperature for 12 hours, and then transfer the soaked rice husk to put into the refrigerator, freeze at -18°C for 8 hours to obtain frozen rice husks, pour the obtained frozen rice husks into a stone mill, and grind for 40 minutes to obtain abrasives, then transfer the obtained abrasives to an oven, and Dry at a temperature of 110°C to a constant weight to obtain dry abrasives, then move the dry abrasives into a carbonization furnace, and feed argon gas into the furnace at a rate of 80mL / min. Rate programming to 450°C, after heat preservation and carbonization for ...

example 2

[0035] In parts by weight, 30 parts of particle diameters are added successively in the mixer to be 5mm fused magnesia, 30 parts of particle diameters are 2mm fused magnesia, 40 parts of particle diameter are 0.8mm fused magnesia, at a speed of Under the condition of 600r / min, stir and mix for 4 hours to obtain graded fused magnesia; mix rice husk and water according to the mass ratio of 1:15, stand and soak at room temperature for 12 hours, and then transfer the soaked rice husk to put into the refrigerator, freeze at -18°C for 8 hours to obtain frozen rice husks, pour the obtained frozen rice husks into a stone mill, and grind for 40 minutes to obtain abrasives, then transfer the obtained abrasives to an oven, and Dry at a temperature of 110°C to a constant weight to obtain dry abrasives, then move the dry abrasives into a carbonization furnace, and feed argon gas into the furnace at a rate of 80mL / min. Rate programming to 450°C, after heat preservation and carbonization for...

example 3

[0037] In parts by weight, 30 parts of particle diameters are added successively in the mixer to be 5mm fused magnesia, 30 parts of particle diameters are 2mm fused magnesia, 40 parts of particle diameter are 0.8mm fused magnesia, at a speed of Under the condition of 600r / min, stir and mix for 4 hours to obtain graded fused magnesia; mix rice husk and water according to the mass ratio of 1:15, stand and soak at room temperature for 12 hours, and then transfer the soaked rice husk to put into the refrigerator, freeze at -18°C for 8 hours to obtain frozen rice husks, pour the obtained frozen rice husks into a stone mill, and grind for 40 minutes to obtain abrasives, then transfer the obtained abrasives to an oven, and Dry at a temperature of 110°C to a constant weight to obtain dry abrasives, then move the dry abrasives into a carbonization furnace, and feed argon gas into the furnace at a rate of 80mL / min. Rate programming to 450°C, after heat preservation and carbonization for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com