Application of a chromium-based metal-organic framework material in olefin polymerization

A metal-organic framework and olefin polymerization technology, applied in the field of metal-organic framework material catalysis, can solve the problems of poor selectivity and low catalytic activity, and achieve the effects of good selectivity, high selectivity and reduced polymerization cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] (1) Stir the chromium metal organic framework material Cr-MIL-101 with ethanol and water at 75°C for 30 minutes to clean the impurity, and treat it in vacuum at 200°C for 2 hours to obtain the high temperature activated chromium metal organic framework material, the catalyst;

[0074] (2) Add 25 μmol catalyst and 5ml toluene to the eggplant bottle placed in the glove box, and stir evenly with a magnetic stirrer; add 50 μmol AlMe 3 , continue magnetic stirring evenly; add 5mmol isoprene and 25μmol [PhNHMe 2 ][B(C 6 f 5 ) 4 ], stirred and reacted for 5h at 20°C, and the above steps were carried out in an anhydrous and oxygen-free environment provided by a glove box;

[0075] (3) The catalyst is filtered out from the eggplant bottle, and 30 mL of ethanol solution of 2,6-di-tert-butyl-4-methylphenol with a mass fraction of 5% is added to terminate the reaction; the reaction solution is carried out with absolute ethanol Settled, precipitated solid matter, vacuum-dried t...

Embodiment 2

[0086] (1) with embodiment 1 step (1);

[0087] (2) [PhNHMe 2 ][B(C 6 f 5 ) 4 ] The addition of 50 μ mol is changed into, all the other are with embodiment 1 step (2);

[0088] (3) With embodiment 1 step (3).

[0089] The following tests were carried out on the chromium metal-organic framework material and the polymerization product after high-temperature activation prepared in this example:

[0090] (1) Powder X-ray Diffraction Detection

[0091] The peak position of the chromium metal organic framework material after high temperature activation is completely consistent with the standard map of the chromium metal organic framework material Cr-MIL-101, which proves that the chromium metal organic framework material after high temperature activation has not collapsed and can be used for catalysis in subsequent steps .

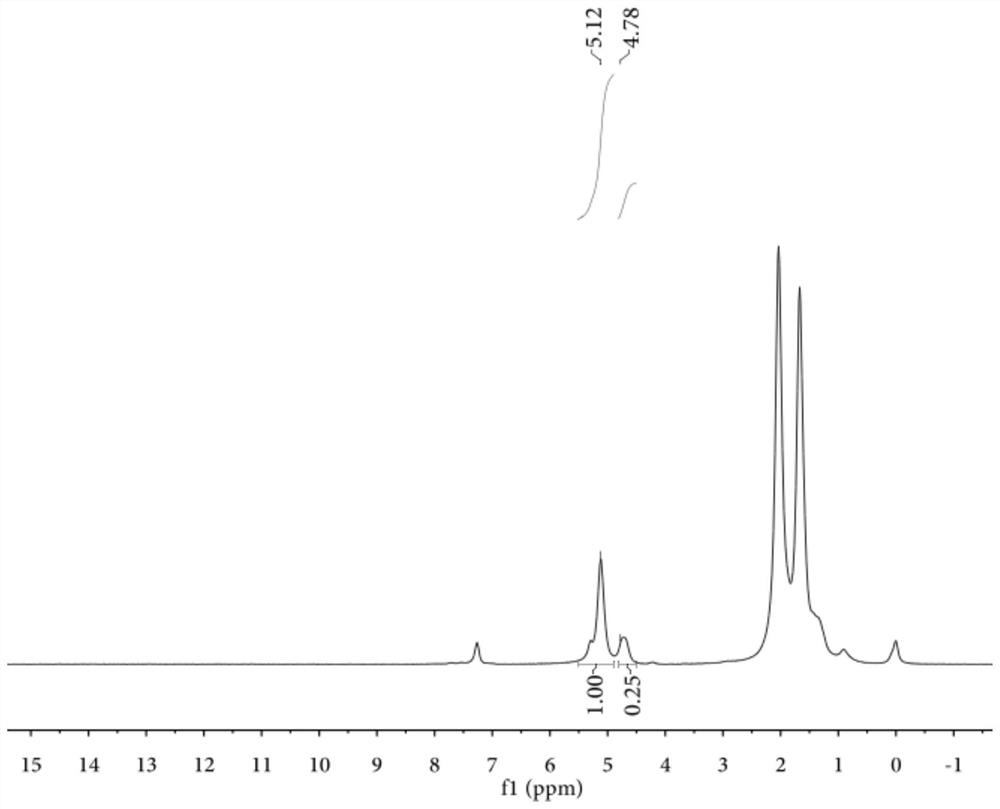

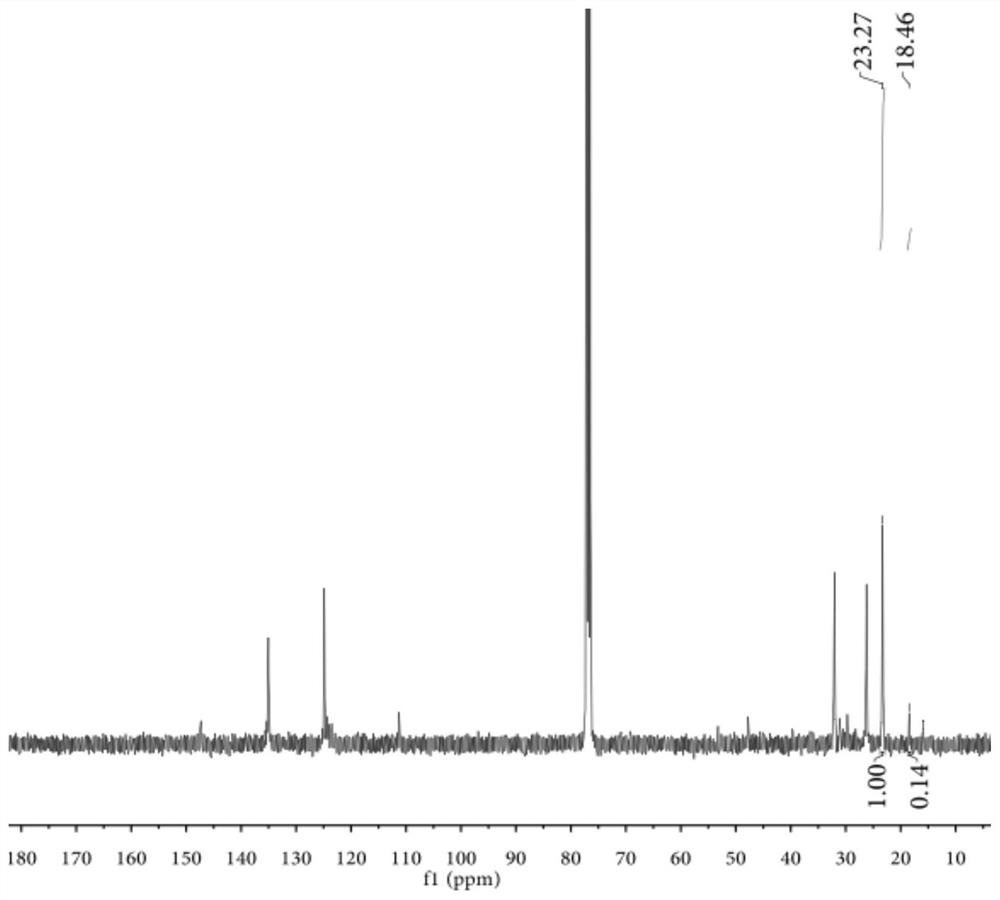

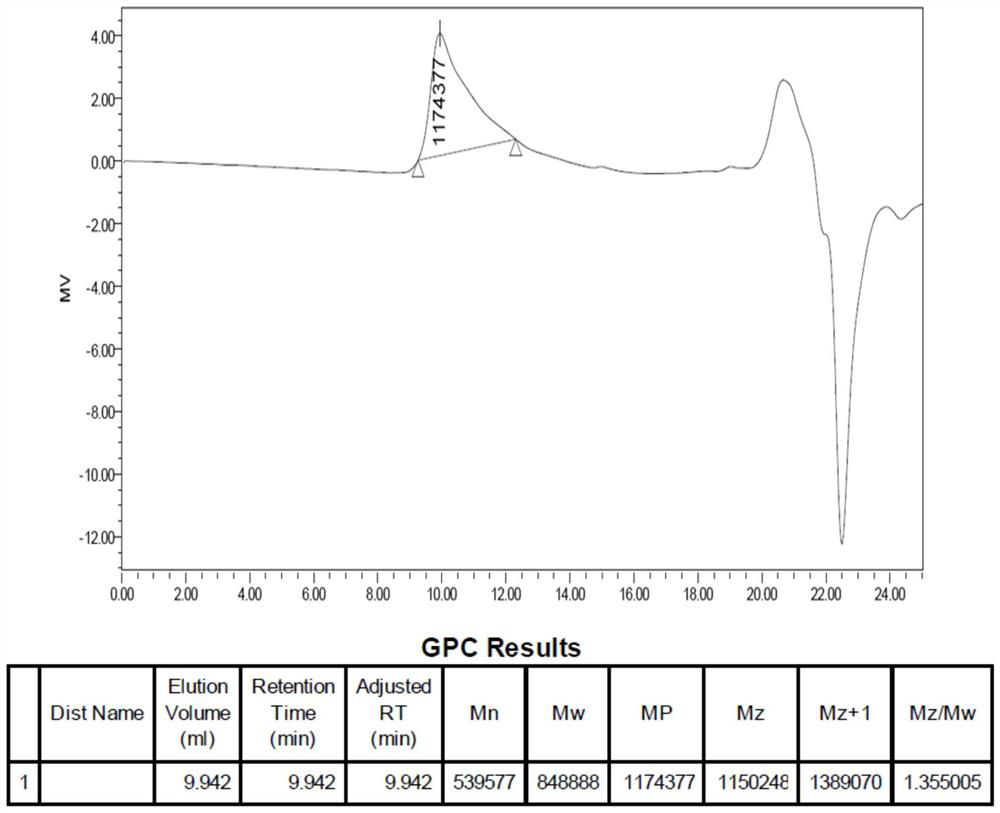

[0092] (2) NMR detection

[0093] The ppm of the NMR spectrum of the polymerization product prepared in this example is the integration at 5.12 and 4.78...

Embodiment 3

[0099] (1) with embodiment 1 step (1);

[0100] (2) [PhNHMe 2 ][B(C 6 f 5 ) 4 ] The addition of 75 μ mol is changed into, and all the other are with embodiment 1 step (2);

[0101] (3) With embodiment 1 step (3).

[0102] The following tests were carried out on the chromium metal-organic framework material and the polymerization product after high-temperature activation prepared in this example:

[0103] (1) Powder X-ray Diffraction Detection

[0104] The peak position of the chromium metal organic framework material after high temperature activation is completely consistent with the standard map of the chromium metal organic framework material Cr-MIL-101, which proves that the chromium metal organic framework material after high temperature activation has not collapsed and can be used for catalysis in subsequent steps .

[0105] (2) NMR detection

[0106] The ppm of the NMR spectrum of the polymerization product prepared in this example is the integration at 5.12 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com