Preparation method of polymer blend gradient functional composite material

A technology of gradient function and composite materials, which is applied in the field of preparation of polymer blend gradient function composite materials, can solve problems such as mutual entanglement, thick gradient membrane materials, and difficulty in phase separation, so as to avoid structural deformation and damage, and is widely used The effect of prospect and process route on environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: A kind of preparation method of polymer blend gradient functional composite material, comprises the following steps:

[0029] Step 1: Preparation of blend system

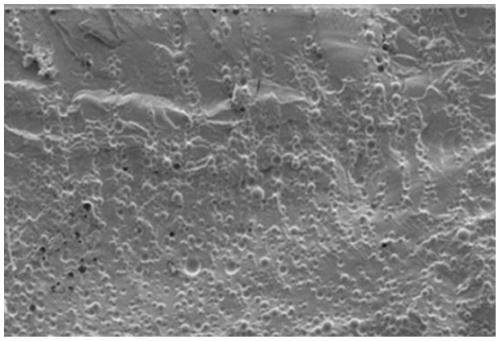

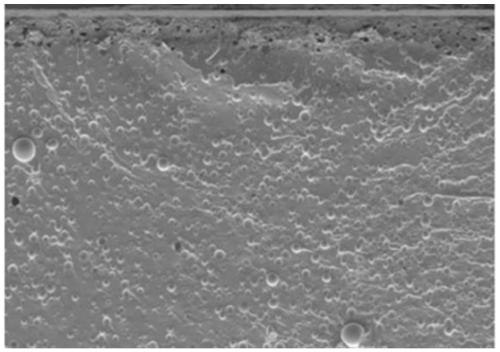

[0030] Weigh 10g of epoxy resin (model E51), 4g of polyamide (model 651), 3g of negatively charged polybutylacrylate micro-nanospheres (diameter is 2um) and blend them, stir mechanically for 5 minutes, and then mix them at room temperature. Ultrasonic dispersion was performed for 30 minutes, and the power of the ultrasonic dispersion device was controlled to 700w.

[0031] Step 2: Form gradient structure driven by DC electric field

[0032] Put the mixed liquid into a transparent conductive glass mold with a thickness of 1mm and connect the positive and negative electrodes. The mold is placed on a heating platform with adjustable temperature. After applying a DC voltage of 2000V / mm, the sample is maintained at 40°C for 30 minutes. After the epoxy resin is gelled, the electric field is removed,...

Embodiment 2

[0033] Embodiment 2: a kind of preparation method of polymer blend gradient functional composite material, comprises the following steps:

[0034] Step 1: Preparation of blend system

[0035] Take by weighing 10g acrylic resin (the model is NOA65, produced by Norland Company), 3g positively charged polystyrene micro-nanospheres (diameter is 2um) blending, first mechanically stirred for 5 minutes, then ultrasonically dispersed at normal temperature for 30 minutes, The power control of the ultrasonic dispersing device is 700w.

[0036] Step 2: Form gradient structure driven by DC electric field

[0037] Put the mixed liquid into a transparent conductive glass mold with a thickness of 1mm and connect the positive and negative electrodes. After applying a DC voltage of 600V / mm, the sample is maintained at 40°C for 10 minutes, cured with 360nm ultraviolet light for 3s, and then the electric field is removed. , to obtain the functional gradient material with polystyrene micro-nano...

Embodiment 4

[0043] Embodiment 4: a kind of preparation method of polymer blend gradient functional composite material, comprises the following steps:

[0044] Step 1: Preparation of blend system

[0045] Weigh 10g of epoxy resin (type E51), 3g of polyamide (type 651), 6g of polybutylacrylate micro-nanospheres (2um in diameter), mechanically stir for 5 minutes, then ultrasonically disperse at room temperature for 30 minutes, and ultrasonically disperse The power control of the device is 700w.

[0046] Step 2: Form gradient structure driven by DC electric field

[0047] Put the mixed liquid into a transparent conductive glass mold with a thickness of 1mm and connect the positive and negative electrodes. The mold is placed on a heating platform with adjustable temperature. After applying a DC voltage of 2000V / mm, the sample is maintained at 40°C for 30 minutes. After the epoxy resin is gelled, the electric field is removed, and the temperature is raised to 70°C for 2 hours. After the epoxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com