Flexible electrode plate with coating layer and preparation method of flexible electrode plate

A flexible electrode and coating technology, applied in the field of electrochemistry, can solve the problems of bulky, damaged, non-flexible, etc., and achieve the effect of increasing the contact area, increasing the contact area, and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of the flexible electrode sheet with coating layer in the present invention specifically comprises the following steps:

[0037] (1) Dispersion: use organic solvent or deionized water as the solvent for the conductive agent, and ultrasonically disperse it at a dispersion concentration of 0.1-2 mg / ml to form a conductive agent slurry; use an organic solvent or deionized water as the solvent for the fiber body, High-speed stirring dispersion, the dispersion concentration is 0.5 ~ 3mg / ml.

[0038] (2) Stir and homogenize: first add the binder to the conductive agent slurry in step (1) and disperse for 2 to 3 minutes, then add the active material, mix well, and then add to the conductive agent slurry in step (1) to disperse well The fibrous body is then fully stirred and mixed evenly to form a suspension slurry.

[0039] (3) Pour the suspension slurry obtained in step (2) into a filter paper suction filter, the filter paper material is preferably cel...

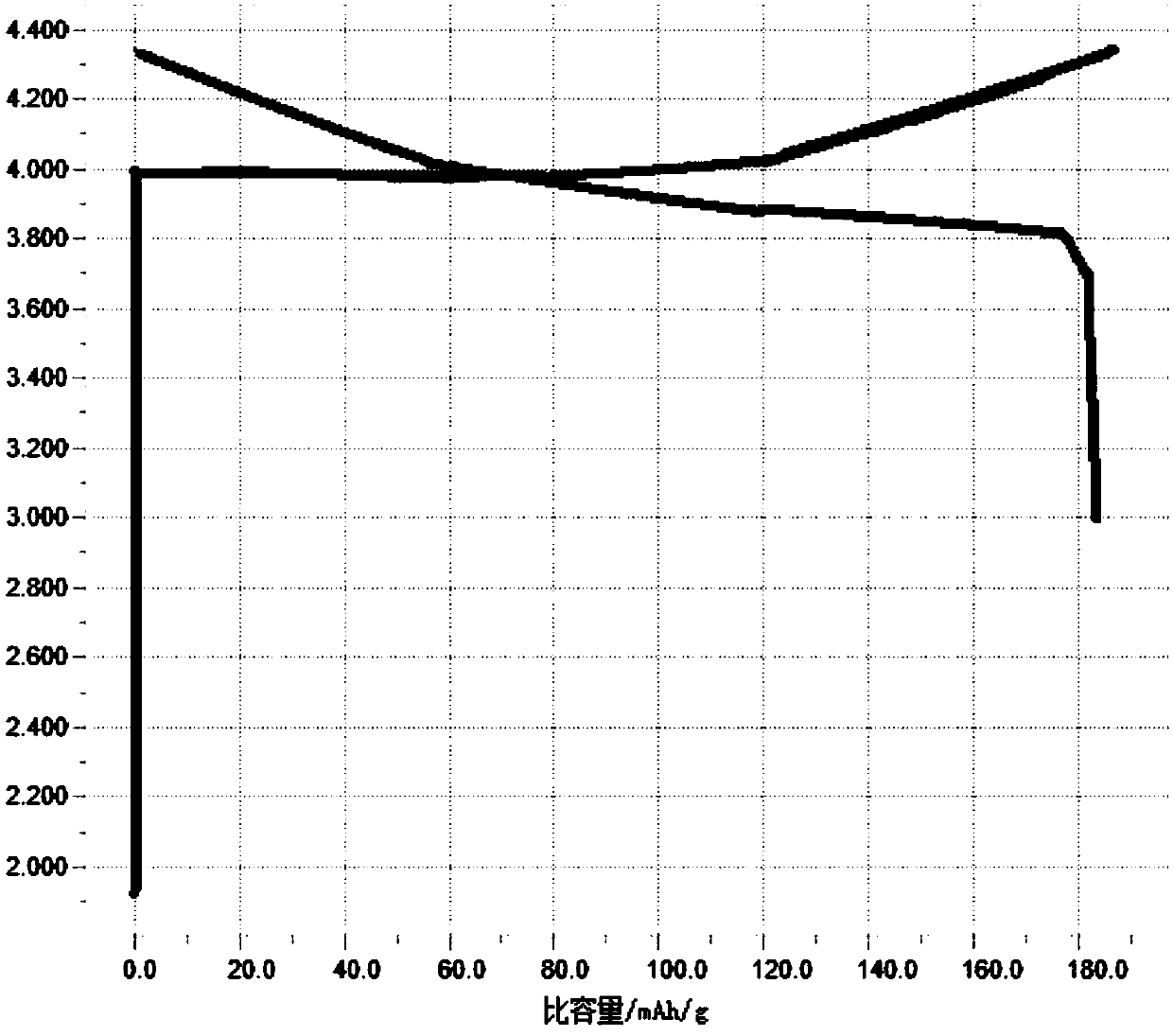

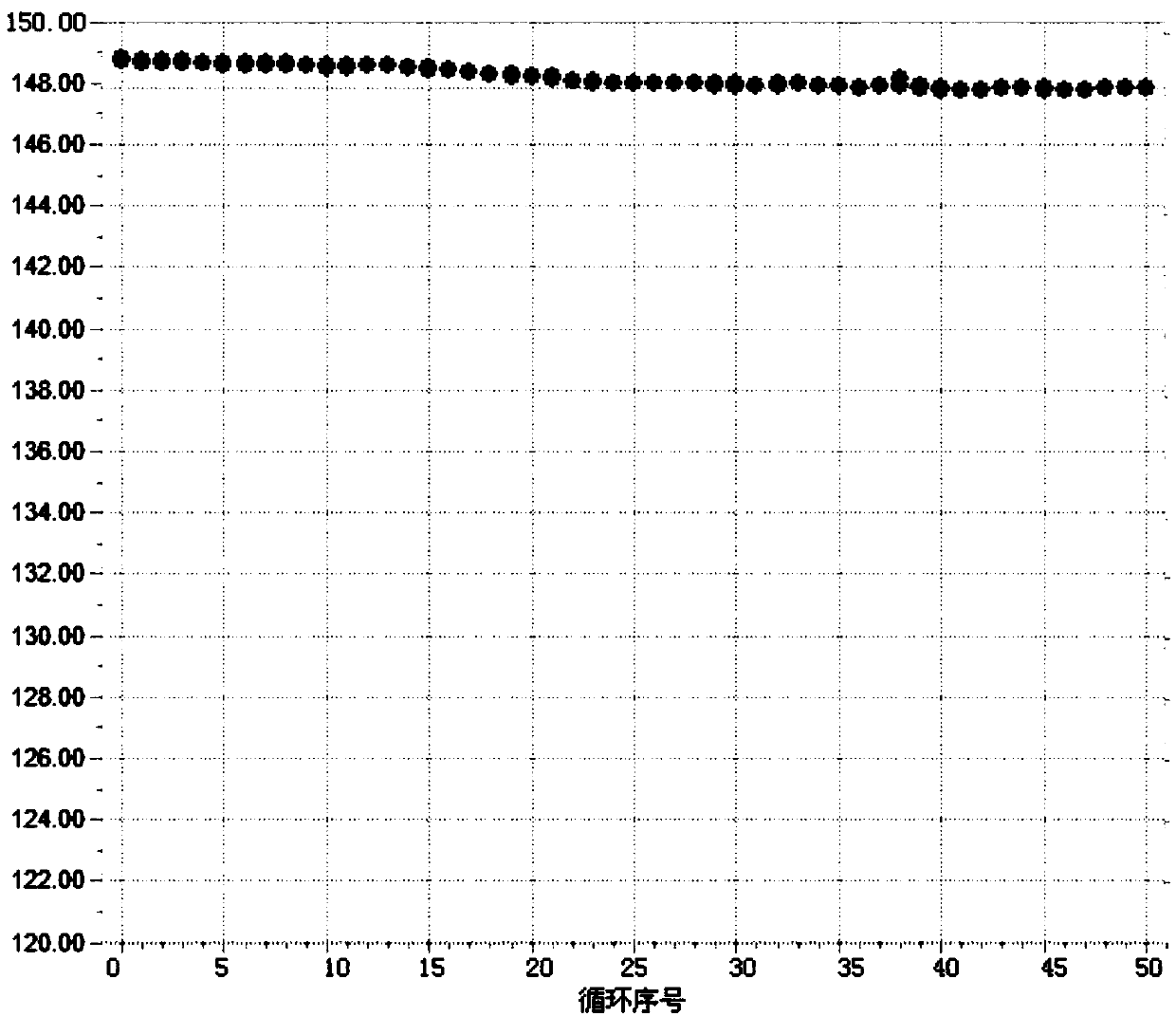

Embodiment 1

[0048] Add carbon nanotubes with a mass fraction of 5% to isopropanol and sonicate for 20 minutes to prepare a conductive agent slurry; disperse lithium cobaltate particles with a mass fraction of 87% in the conductive agent slurry, stir at high speed for 10 minutes, and cobalt acid Lithium particles according to surface density 20mg / cm 2 Prepare a mixed solution of conductive agent 1 and active material; then take nanocellulose with a mass fraction of 8% as a fiber body, add isopropanol to high-speed stirring and disperse for 5 minutes, and mix the dispersed fiber body with the prepared conductive agent 1 and the active material. The mixtures were mixed with each other and stirred at high speed for 10 minutes to prepare a suspension slurry; the suspension was poured into cellulose filter paper for vacuum filtration, and after the filtrate was completely drained, the filter paper and the filtered sediment were removed together and dried , the drying temperature was 120°C, and ...

Embodiment 2

[0052] Take a graphene slurry with a mass fraction of 5% and add it into deionized water for ultrasonication for 20 minutes to prepare a conductive agent slurry; disperse graphite particles with a mass fraction of 89% in the conductive agent slurry, stir at high speed for 15 minutes, and the graphite particles are pressed on the surface. Density 30mg / cm 2 Prepare a mixed solution of conductive agent 1 and the active substance; then take nanocellulose with a mass fraction of 5% as a fiber body and add it to deionized water for high-speed stirring and disperse for 12 minutes, and mix the dispersed fiber body with the prepared conductive agent 1 and the active substance The mixed liquids were mixed with each other and stirred at high speed for 20 minutes to prepare a suspension slurry; secondly, nanofibers with a mass fraction of 1% were selected as the cushion material, and the cushion material was dispersed in deionized water for 3 minutes at a high speed, and the surface densit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap