Nanometer carbon fiber copper powder-loaded composite paste

A technology of nano-carbon fiber and composite slurry, which is applied in the direction of conductive materials dispersed in non-conductive inorganic materials, parts of fixed capacitors, electrical components, etc., and can solve problems such as unsuitable for industrial production, limited adhesion, and high cost , to achieve the effect of not easy copper ion diffusion, strong anti-aging ability and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

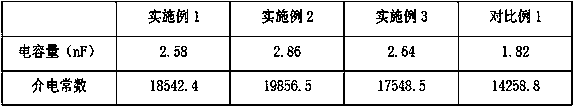

Examples

Embodiment 1

[0016] A composite slurry of nano-carbon fiber loaded copper powder, comprising the following components by weight: 30 parts of nano-copper powder, 12 parts of nano-carbon fiber, 20 parts of glass powder, 20 parts of organic solvent, 2 parts of xylene, hydrophilic 22 parts of high-molecular compounds, 8 parts of additives; the particle size of the carbon nanofiber is 20 μm, and the porosity is 65%; the organic solvent is formed by mixing dopamine solution, chitosan and isopropanol, and The weight ratio with isopropanol is 2:1:1.

[0017] Wherein, the hydrophilic polymer compound is a condensation product of polyvinyl alcohol, ethylene oxide, and glycerol, with an average molecular weight of 4000 and a molar ratio of 3:2:1.

[0018] The specific surface area of the nano copper powder is 25m 2 / g.

[0019] The auxiliary agent is formed by mixing silane coupling agent KH792, leveling agent and hydrogenated castor oil.

[0020] The concentration of the dopamine solution is 1m...

Embodiment 2

[0023] A composite slurry of nano-carbon fiber loaded copper powder, comprising the following components by weight: 45 parts of nano-copper powder, 22 parts of nano-carbon fiber, 25 parts of glass powder, 26 parts of organic solvent, 6 parts of xylene, hydrophilic 25 parts of permanent high molecular compound, 10 parts of additives.

[0024] The hydrophilic macromolecular compound is a condensation product of polyvinyl alcohol, ethylene oxide, and glycerin, with an average molecular weight of 5000 and a molar ratio of 3:2:1.

[0025] The specific surface area of the nano copper powder is 32m 2 / g.

[0026] The auxiliary agent is formed by mixing silane coupling agent KH792, leveling agent and hydrogenated castor oil.

[0027] The concentration of the dopamine solution is 1.5mol / L.

[0028] Specifically, after dissolving carbon nanofibers in an organic solvent and immersing them at low temperature for 20-40 hours, adding nanometer copper powder, stirring evenly, and then s...

Embodiment 3

[0030] A composite slurry of nano-carbon fiber loaded copper powder, comprising the following components by weight: 50 parts of nano-copper powder, 24 parts of nano-carbon fiber, 28 parts of glass powder, 30 parts of organic solvent, 8 parts of xylene, hydrophilic 28 parts of high-molecular compounds, 12 parts of additives; the particle size of the carbon nanofibers is 30 μm, and the porosity is ≥ 65%; the organic solvent is formed by mixing dopamine solution, chitosan and isopropanol The weight ratio of sugar and isopropanol is 5:2:1.

[0031] The hydrophilic macromolecular compound is a condensation product of polyvinyl alcohol, ethylene oxide, and glycerol, with an average molecular weight of 6000 and a molar ratio of 3:2:1.

[0032] The specific surface area of the nano copper powder is 40m 2 / g.

[0033] The auxiliary agent is formed by mixing silane coupling agent KH792, leveling agent and hydrogenated castor oil.

[0034] The concentration of the dopamine solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com