A composite slurry of nano-carbon fiber loaded copper powder

A nano-carbon fiber and composite slurry technology, which is applied to conductive materials dispersed in non-conductive inorganic materials, components of fixed capacitors, capacitors, etc., can solve the problems of unsuitability for industrial production, limited adhesion, and high cost. Achieve the effect of not easy copper ion diffusion, strong anti-aging ability and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

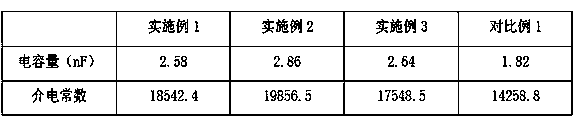

Examples

Embodiment 1

[0016] A composite slurry of nano-carbon fiber loaded copper powder, comprising the following components by weight: 30 parts of nano-copper powder, 12 parts of nano-carbon fiber, 20 parts of glass powder, 20 parts of organic solvent, 2 parts of xylene, hydrophilic 22 parts of high-molecular compounds, 8 parts of additives; the particle size of the carbon nanofiber is 20 μm, and the porosity is 65%; the organic solvent is formed by mixing dopamine solution, chitosan and isopropanol, and The weight ratio with isopropanol is 2:1:1.

[0017] Wherein, the hydrophilic polymer compound is a condensation product of polyvinyl alcohol, ethylene oxide, and glycerol, with an average molecular weight of 4000 and a molar ratio of 3:2:1.

[0018] The specific surface area of the nano copper powder is 25m 2 / g.

[0019] The auxiliary agent is formed by mixing silane coupling agent KH792, leveling agent and hydrogenated castor oil.

[0020] The concentration of the dopamine solution is 1m...

Embodiment 2

[0023] A composite slurry of nano-carbon fiber loaded copper powder, comprising the following components by weight: 45 parts of nano-copper powder, 22 parts of nano-carbon fiber, 25 parts of glass powder, 26 parts of organic solvent, 6 parts of xylene, hydrophilic 25 parts of permanent high molecular compound, 10 parts of additives.

[0024] The hydrophilic macromolecular compound is a condensation product of polyvinyl alcohol, ethylene oxide, and glycerin, with an average molecular weight of 5000 and a molar ratio of 3:2:1.

[0025] The specific surface area of the nano copper powder is 32m 2 / g.

[0026] The auxiliary agent is formed by mixing silane coupling agent KH792, leveling agent and hydrogenated castor oil.

[0027] The concentration of the dopamine solution is 1.5mol / L.

[0028] Specifically, after dissolving carbon nanofibers in an organic solvent and immersing them at low temperature for 20-40 hours, adding nanometer copper powder, stirring evenly, and then s...

Embodiment 3

[0030] A composite slurry of nano-carbon fiber loaded copper powder, comprising the following components by weight: 50 parts of nano-copper powder, 24 parts of nano-carbon fiber, 28 parts of glass powder, 30 parts of organic solvent, 8 parts of xylene, hydrophilic 28 parts of high-molecular compounds, 12 parts of additives; the particle size of the carbon nanofibers is 30 μm, and the porosity is ≥ 65%; the organic solvent is formed by mixing dopamine solution, chitosan and isopropanol The weight ratio of sugar and isopropanol is 5:2:1.

[0031] The hydrophilic macromolecular compound is a condensation product of polyvinyl alcohol, ethylene oxide, and glycerol, with an average molecular weight of 6000 and a molar ratio of 3:2:1.

[0032] The specific surface area of the nano copper powder is 40m 2 / g.

[0033] The auxiliary agent is formed by mixing silane coupling agent KH792, leveling agent and hydrogenated castor oil.

[0034] The concentration of the dopamine solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com