Method for preparing 2, 6-naphthalic acid through oxidizing 2-methyl-6-propionyl naphthalene

A technology of propionyl naphthalene and naphthalene dicarboxylic acid, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylate, etc., can solve the problems of high energy consumption, inability to obtain ideal product yield, high equipment requirements, etc., and achieve The effect of low reaction temperature, suppression of product color blackening, and less by-product formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

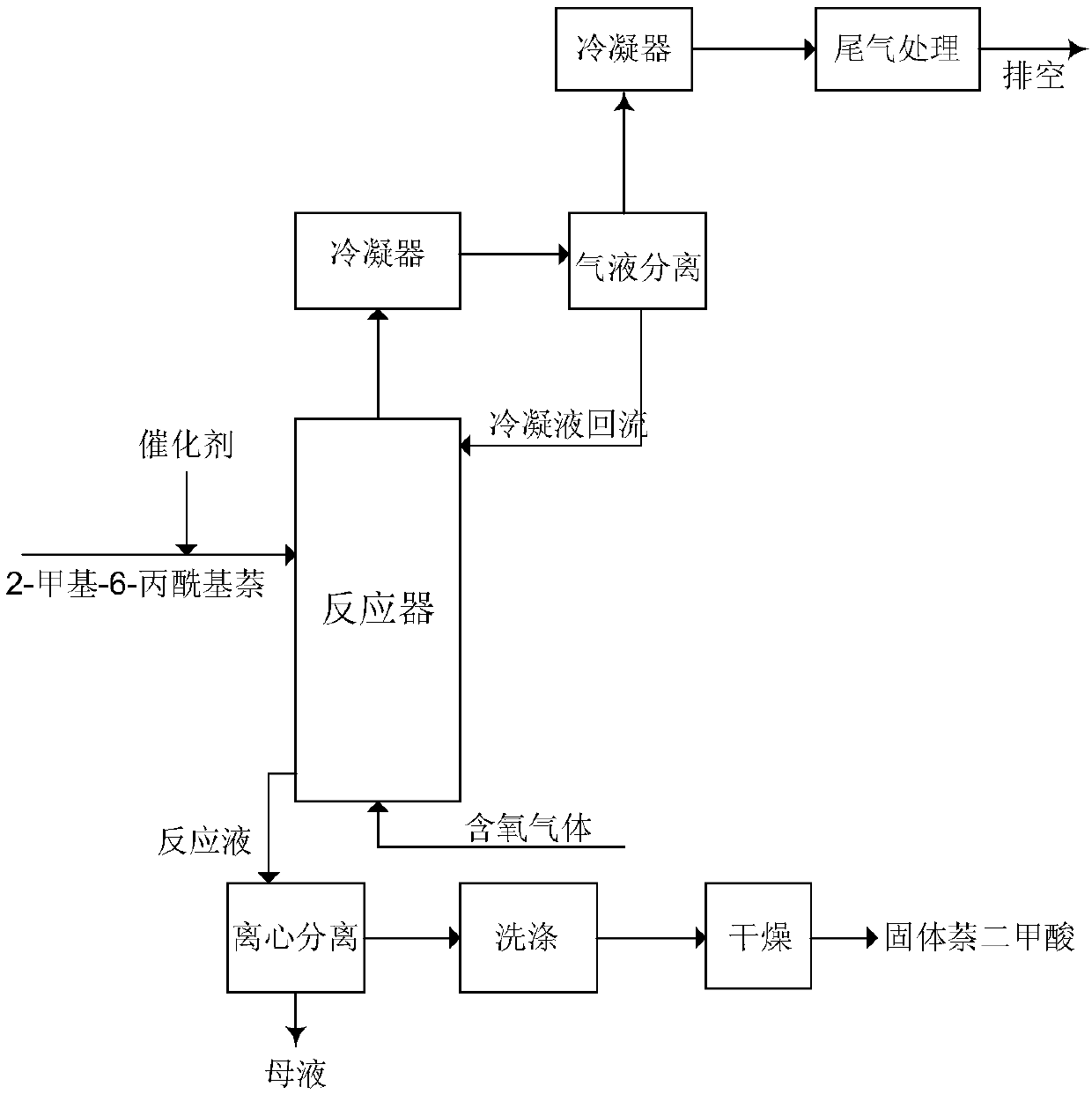

Embodiment 1

[0027] In the gas-liquid bubbling and stirring high-pressure reactor, the stirring speed is 600r / min, stirring and heating to 175°C, using N 2 Pressurize to 1.8MPa; mix and dissolve 120g of glacial acetic acid, 5.80g of cobalt acetate tetrahydrate, 4.98g of manganese acetate tetrahydrate, 7.14g of potassium bromide, and 8.58g of potassium acetate. Continuous supply of 3.0 liters (standard state) / min; 72.6g of 2-methyl-6-propionylnaphthalene dissolved with 100g of glacial acetic acid is continuously supplied by a metering pump. After the material stays in the reactor for an average of 2 hours, the bottom of the reactor is The height of the outflow pipe is kept at the same height as the liquid level in the reactor, and the material overflows to ensure that there is sufficient solvent and raw materials in the reactor to maintain the reaction; after the reaction liquid is cooled and solid-liquid separated, the mother liquid is reused, as shown in the attached figure 1 shown. The ...

Embodiment 13

[0035] Embodiment 1.3: Recover mother liquor and solvent after centrifugation

[0036] The mother liquor after the centrifugation of Example 1 and the acetic acid after washing are returned in the reactor as raw materials, do not add catalyst and co-catalyst, other are the same as Example 1, carry out oxidation reaction;

[0037] After drying, 60.33 g of khaki solid powder was obtained. The purity and yield of 2,6-naphthalene dicarboxylic acid after liquid phase analysis were 95.6% and 83.1%, respectively.

[0038] After the mother liquor after the secondary centrifugation and the acetic acid after washing are returned in the reactor as a raw material, and the potassium bromide and 2.0g potassium acetate of 2.28g and 2.0g potassium acetate, and 20g glacial acetic acid are supplemented according to the feeding ratio for the first time among the embodiment 1, Others carry out oxidation reaction with embodiment 1;

[0039]After drying, 58.44 g of khaki solid powder was obtained...

Embodiment 2

[0041] In the gas-liquid bubbling and stirring autoclave, the stirring speed is 600r / min, stirring and heating to 170°C, and pressurizing with N2 to 1.6MPa; 200g of glacial acetic acid and 50.0g of propionic acid and 9.93g of cobalt acetate tetrahydrate, 6.73 G manganese acetate tetrahydrate, 9.64g potassium bromide, and 15.82g potassium acetate are mixed and dissolved, and are continuously added to the oxidation reactor by a metering pump; compressed air is continuously supplied to the reactor at 3.0 liters (standard state) / min; 260g glacial acetic acid Dissolved with 111.38g 2-methyl-6-propionylnaphthalene and continuously supplied by metering pump, the material stays in the reactor for an average of 1 hour, and the height of the outflow pipe at the bottom of the reactor is maintained at the same height as the liquid level in the reactor, and the overflow is discharged, so that It can ensure that there are sufficient solvents and raw materials in the reactor to maintain the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com