High throughput antibacterial composite nanofiltration membrane and preparation method thereof

A composite nanofiltration membrane, high-throughput technology, applied in the field of membrane separation, can solve problems such as complicated processes, and achieve the effects of simple and mild method, high bacteriostatic rate, and high-throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

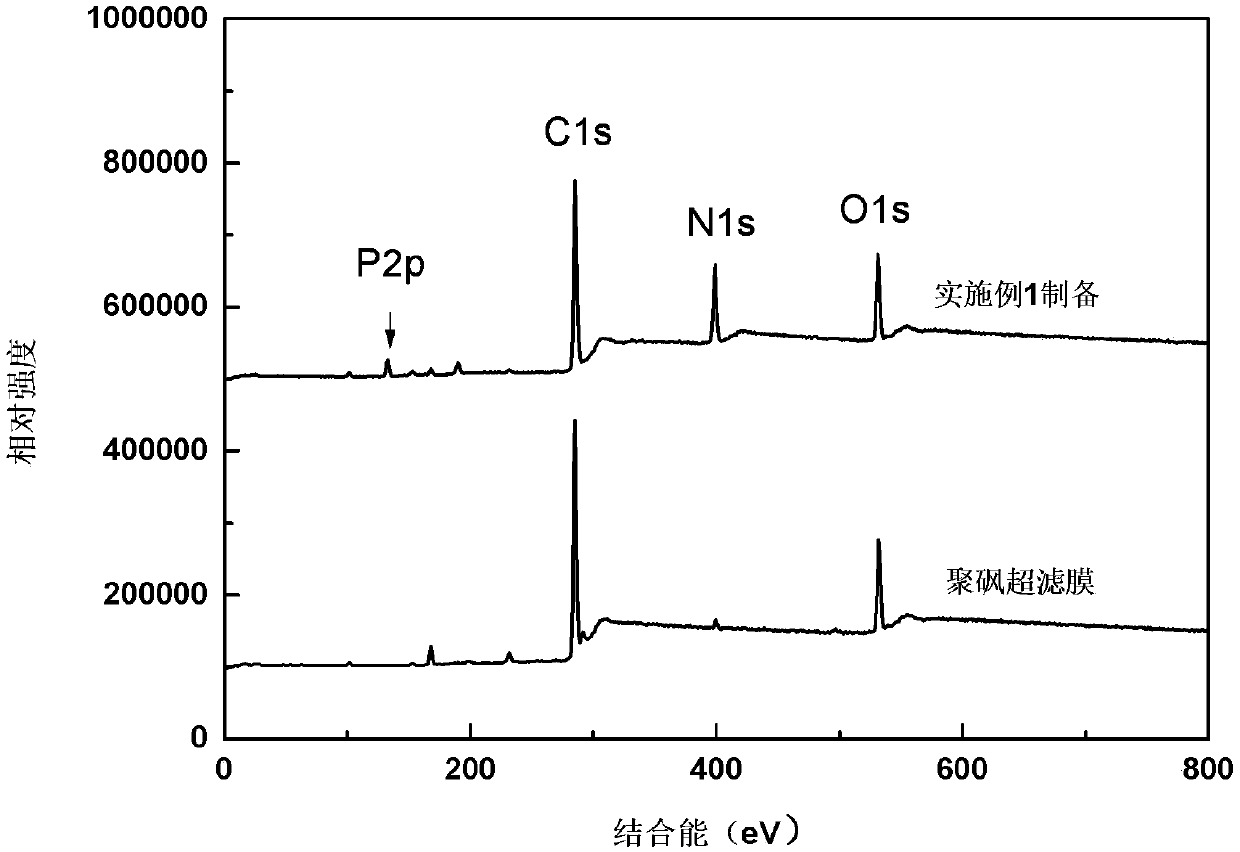

Embodiment 1

[0022] A method for preparing a high-throughput antibacterial composite nanofiltration membrane, comprising the steps of:

[0023] (1) branched polyethyleneimine (Mn=10000) and triethylamine are added in water, obtain branched polyethyleneimine mass percent concentration and be 0.1%, the mass percent concentration of triethylamine is the aqueous phase of 2%, Contact the functional layer of the polysulfone (Mw=30000) ultrafiltration membrane with the water phase for 600s, and remove the excess water phase on the surface of the membrane by rolling with a rubber roller;

[0024] (2) Phosphazene tripolychloride is put into normal hexane and is made into the organic phase solution that mass percent concentration is 0.2%, and the surface that the film that step (1) obtains is contacted with water phase again with described organic phase solution Contact for 30s to remove excess organic phase solution on the surface of the membrane;

[0025] (3) Place the membrane obtained in step (...

Embodiment 2

[0028] A method for preparing a high-throughput antibacterial composite nanofiltration membrane, comprising the steps of:

[0029] (1) branched polyethyleneimine (Mn=1800) and sodium hydroxide are added in water, obtain branched polyethyleneimine mass percent concentration and be 5%, the mass percent concentration of sodium hydroxide is the aqueous phase of 2%, Contact the functional layer of the ultrafiltration membrane made of polyacrylonitrile (Mw=100000) with the water phase for 600s to remove excess water phase on the surface of the membrane;

[0030] (2) putting trimeric phosphazene chloride into Isopar G to make an organic phase solution with a mass percentage concentration of 1.5%, the surface of the membrane obtained in step (1) in contact with the water phase is then mixed with the organic phase solution Contact for 60s to remove excess organic phase solution on the surface of the membrane;

[0031] (3) Place the membrane obtained in step (2) at 80° C. for 1 min; wa...

Embodiment 3

[0034] A method for preparing a high-throughput antibacterial composite nanofiltration membrane, comprising the steps of:

[0035] (1) branched polyethylenimine (Mn=60000) and sodium bicarbonate are added in water, obtain branched polyethyleneimine mass percent concentration and be 1%, the mass percent concentration of sodium bicarbonate is the aqueous phase of 1%, Contact the functional layer of the ultrafiltration membrane made of polyvinylidene fluoride (Mw=50000) with the water phase for 30 seconds to remove excess water phase on the membrane surface;

[0036] (2) putting the dioxophosphonitrile fluorinated trimer into n-heptane to make an organic phase solution with a mass percent concentration of 0.5%, and

[0037] The surface of the membrane obtained in step (1) in contact with the water phase is then contacted with the organic phase solution for 180s to remove excess organic phase solution on the membrane surface;

[0038] (3) Place the membrane obtained in step (2) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com