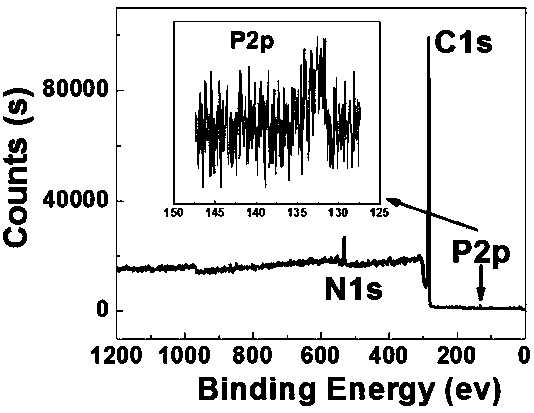

Preparation method of porous nitrogen and phosphorus dual-doped carbon oxygen reduction catalyst

A dual-doping and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of lengthy implementation procedures and insufficient catalytic activity of oxygen reduction, and achieve excellent resistance to methanol interference and carbon monoxide poisoning performance, excellent oxygen reduction catalytic performance, and enhanced electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

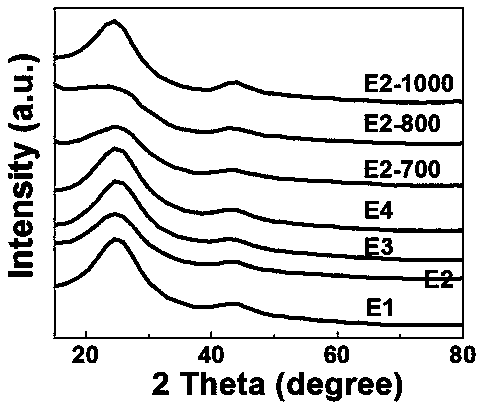

Embodiment 1

[0027] (1) Put 3g of dry and clean biomass precursor white jade mushroom and 30mL of ultrapure water in an autoclave for hydrothermal reaction at 180°C for 24 hours. Dry at 80°C for 10 hours in a blast drying oven to obtain material A;

[0028] (2) Aqueous ammonia solution (0.011mol NH 3 ·H 2 O) Add dropwise to zinc chloride aqueous solution (0.022mol ZnCl 2 ) to obtain a mixed double activator solution B1 containing both zinc hydroxide and zinc chloride, immerse 1g of material A in the mixed double activator solution B1 and mix evenly, then place it in a blast drying oven at 105°C Drying for 10 hours to obtain material C1, that is, to complete the carbonization pretreatment process;

[0029] (3) Transfer the material C1 to a porcelain boat and place it in a tube furnace. Under the protection of nitrogen gas with a flow rate of 100mL / min, raise the temperature from room temperature to 300°C for 2h after 60min, and then increase the temperature at a rate of 10°C / min. Raise ...

Embodiment 2

[0032] (1) Ammonia solution (0.022mol NH 3 ·H 2 O) Add dropwise to zinc chloride aqueous solution (0.022mol ZnCl 2 ) to obtain a mixed double activator solution B2 containing both zinc hydroxide and zinc chloride, immerse 1g of material A in the mixed double activator solution B2 and mix evenly, then place it in a blast drying oven at 105°C Drying for 10 hours to obtain material C2, that is, the carbonization pretreatment process is completed;

[0033] (2) Transfer the material C2 to a porcelain boat and place it in a tube furnace. Under the protection of nitrogen gas with a flow rate of 100mL / min, raise the temperature from room temperature to 300°C for 2h after 60min, and then increase the temperature at a rate of 10°C / min. Raise the temperature to 900°C for 2 hours, then naturally cool down to room temperature to obtain material D2;

[0034] (3) Transfer the material D2 to a reaction vessel and add 100mL of hydrochloric acid solution with a molar concentration of 2mol / L ...

Embodiment 3

[0036] (1) Ammonia solution (0.033mol NH 3 ·H 2 O) Add dropwise to zinc chloride aqueous solution (0.022mol ZnCl 2 ) to obtain a mixed double activator solution B3 containing both zinc hydroxide and zinc chloride, immerse 1g of material A in the mixed double activator solution B3 and mix evenly, then place it in a blast drying oven at 105°C Drying for 10 hours to obtain material C3, that is, the carbonization pretreatment process is completed;

[0037] (2) Transfer the material C3 to a porcelain boat and place it in a tube furnace. Under the protection of nitrogen gas with a flow rate of 100mL / min, raise the temperature from room temperature to 300°C for 2h after 60min, and then increase the temperature at a rate of 10°C / min. Raise the temperature to 900°C for 2 hours, then naturally cool down to room temperature to obtain material D3;

[0038] (3) Transfer the material D3 to a reaction vessel and add 100mL of hydrochloric acid solution with a molar concentration of 2mol / L ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com