Neutral scale remover for gathering and transporting system and water injection system in oilfield

A technology for gathering and transportation systems and water injection systems, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as equipment metal material corrosion, equipment and personnel safety hazards, pump stuck, etc., to achieve stable operation and avoid secondary problems The effect of secondary stuck pumps or blockages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of neutral descaling agent for oil field gathering and transportation system and water injection system, its mass percentage is composed of: the mass fraction of sodium nitrilotriacetate is 15%, the mass fraction of ethylenediamine tetramethylene phosphonate is 10%, and the mass fraction of diethyl The mass fraction of triaminepentaacetic acid is 6%, the mass fraction of tetrakis hydroxymethyl phosphorus sulfate is 5%, the mass fraction of potassium sodium tartrate is 4%, the mass fraction of ammonium citrate is 1.5%, the mass fraction of Pingpingjia AEO-9 is 0.5%, OEP- 70 mass fraction 0.2%, water mass fraction 57.8%.

[0032] The neutral descaling agent used in the oilfield gathering and transportation system and water injection system is mechanically mixed sodium triacetate, sodium ethylenediamine tetramethylene phosphonate, diethylene triamine pentaacetic acid, tetrakis hydroxymethyl phosphorus sulfate, potassium tartrate Sodium, ammonium citrate, AEO-9 and O...

Embodiment 2

[0035] A kind of neutral descaling agent for oil field gathering and transportation system and water injection system, its mass percentage is composed of: the mass fraction of sodium nitrilotriacetate is 10%, the mass fraction of ethylenediamine tetramethylene phosphonate is 15%, and the mass fraction of diethyl The mass fraction of triamine pentaacetic acid is 10%, the mass fraction of tetrakis hydroxymethyl phosphorus sulfate is 8%, the mass fraction of potassium sodium tartrate is 6%, the mass fraction of ammonium citrate is 1.5%, the mass fraction of Pingpingjia AEO-9 is 0.5%, OEP- 70 mass fraction 0.5%, water mass fraction 48.5%.

[0036] The neutral descaling agent used in the oilfield gathering and transportation system and water injection system is mechanically mixed sodium triacetate, sodium ethylenediamine tetramethylene phosphonate, diethylene triamine pentaacetic acid, tetrakis hydroxymethyl phosphorus sulfate, potassium tartrate Sodium, ammonium citrate, AEO-9 and...

Embodiment 3

[0039] Preparation and application of neutral descaling agent WCG-3355 for oilfield subsea pipeline:

[0040] Component ratio (by mass): the mass fraction of sodium nitrilotriacetate is 15%, the mass fraction of sodium ethylenediamine tetramethylene phosphonate is 10%, the mass fraction of diethylene triamine pentaacetic acid is 8%, and the mass fraction of tetrahydroxy The mass fraction of phosphorous methyl sulfate is 5%, the mass fraction of potassium sodium tartrate is 2%, the mass fraction of ammonium citrate is 1%, the mass fraction of Pinpinga AEO-9 is 0.2%, the mass fraction of OEP-70 is 0.1%, and the mass fraction of water is 58.7%.

[0041] Preparation method: mechanically mix according to the formula

[0042] Subject of the experiment: descaling of sea pipes on an offshore platform

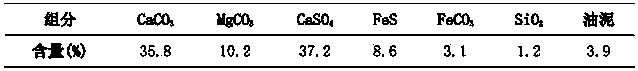

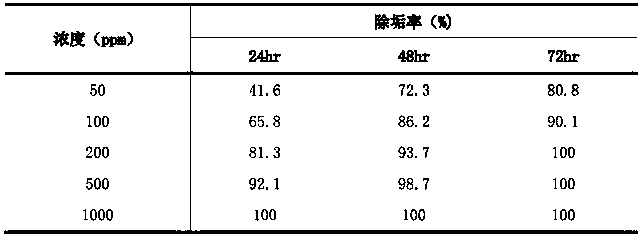

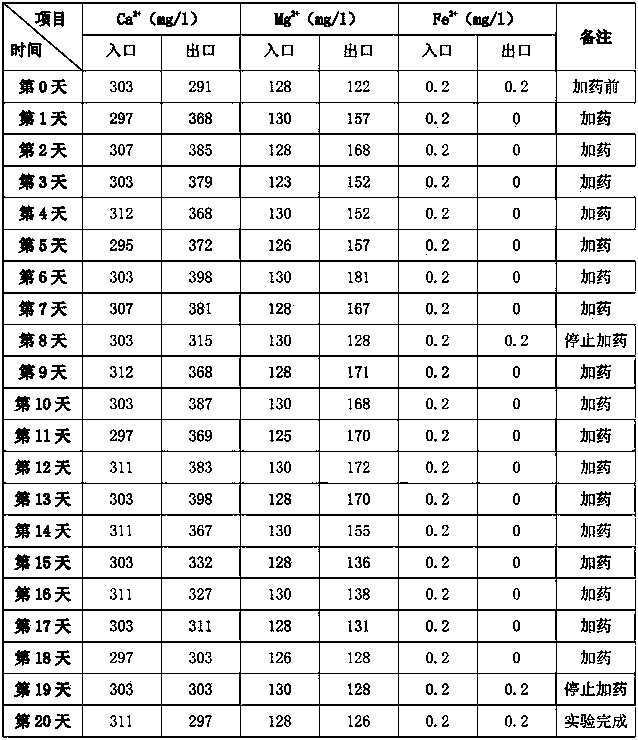

[0043]Experimental method: Take 100ml of experimental water sample, add the same weight of on-site scale sample, see Table 1 for the analysis results of the scale sample, add different...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com