A kind of double crosslinking point monomer carboxylic acid type acrylate rubber and its preparation method

An acrylate and carboxylic acid type technology, used in the rubber field, can solve the problems of inability to take into account other properties, use restrictions, affect low temperature performance, etc. burn effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

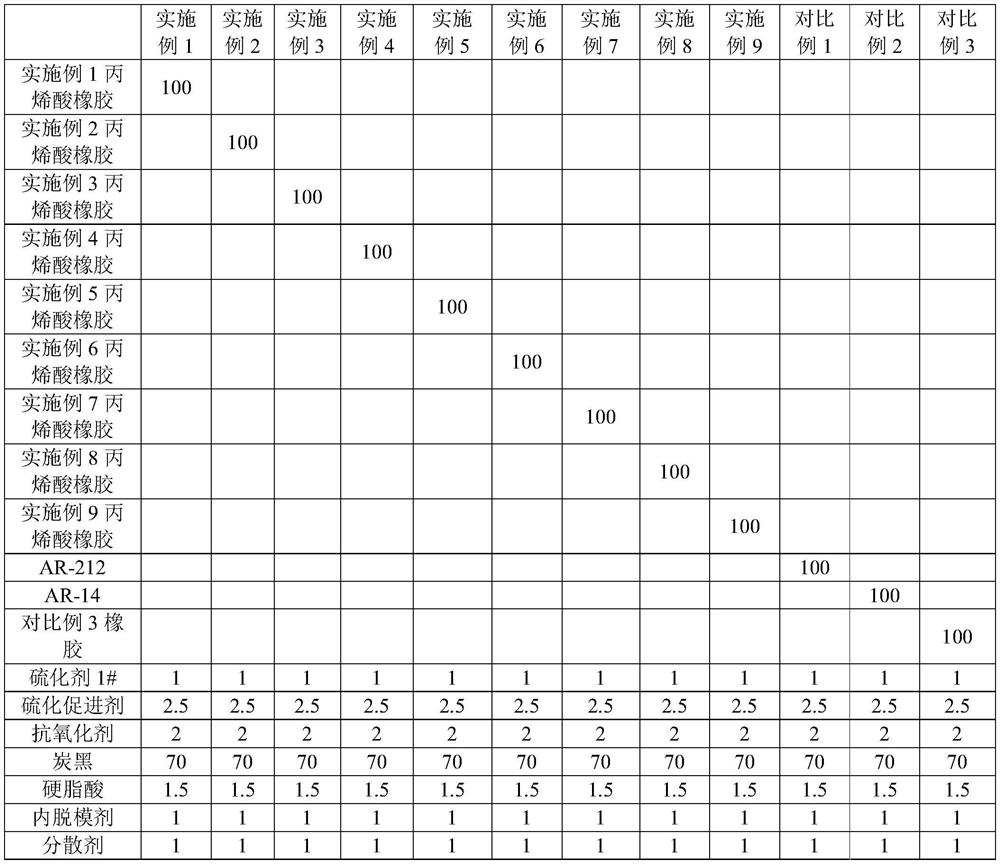

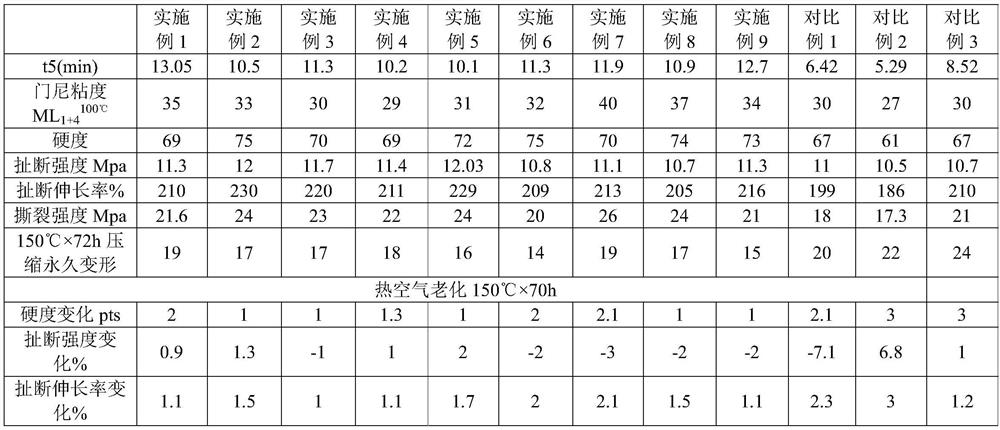

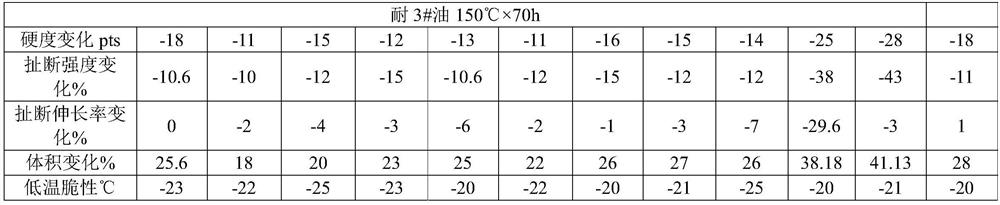

Examples

Embodiment 1

[0056] S1. Add 50 parts of deionized water into the emulsification tank, then add 4 parts of sodium dodecylsulfonate, and 0.3 parts of ammonium persulfate are dissolved by mechanical stirring to obtain the solution A of the emulsifier;

[0057] S2. Mix 60 parts of ethyl acrylate, 25 parts of butyl acrylate, 12 parts of methoxyethyl acrylate, 2 parts of monoethyl maleate, 1 part of diethylene glycol monobutyl ether maleate and 0.05 parts of n- After the dodecyl mercaptan is mixed evenly, the monomer mixed phase B is obtained;

[0058] S3. Add the monomer mixed phase B to the solution A of the emulsifier, emulsify at room temperature and under the protection of nitrogen, and the emulsification time is 30 minutes to obtain the mixture emulsion C;

[0059] S4. Add 100 parts of water into the reaction kettle, maintain under the protection of nitrogen, stir and raise the temperature to 60°C;

[0060] S5. Transfer 1 / 5 parts by weight of the mixture emulsion C to the reactor, and und...

Embodiment 2

[0065] S1. Add 80 parts of deionized water into the emulsification tank, then add 3 parts of sodium dodecylsulfonate, and 0.3 parts of ammonium persulfate are dissolved by mechanical stirring to obtain the solution A of the emulsifier;

[0066] S2. Mix 5 parts of methyl propylene, 45 parts of ethyl acrylate, 18 parts of butyl acrylate, 24 parts of methoxyethyl acrylate, 5 parts of monoethyl maleate, 3 parts of diethylene glycol monobutyl maleate After the ether ester and 0.1 part of n-dodecyl mercaptan are uniformly mixed, the monomer mixed phase B is obtained;

[0067] S3. Add the monomer mixed phase B to the solution A of the emulsifier, emulsify at room temperature and under the protection of nitrogen, and the emulsification time is 30 minutes to obtain the mixture emulsion C;

[0068] S4. Add 120 parts of water into the reaction kettle, maintain under the protection of nitrogen, stir and raise the temperature to within the range of 70°C;

[0069] S5. Transfer 1 / 5 part by ...

Embodiment 3

[0074] S1. Add 80 parts of deionized water to the emulsification tank, then add 2 parts of sodium dodecylbenzenesulfonate, and 0.3 parts of potassium persulfate are dissolved by mechanical stirring to obtain the solution A of the emulsifier;

[0075] S2. Mix 45 parts of ethyl acrylate, 20 parts of butyl acrylate, 30 parts of methoxyethyl acrylate, 3 parts of monobutyl maleate, 2 parts of diethylene glycol monobutyl ether maleate and 0.08 parts After the n-dodecyl mercaptan is mixed evenly, the monomer mixed phase B is obtained;

[0076] S3. Add the monomer mixed phase B to the solution A of the emulsifier, emulsify at room temperature and under the protection of nitrogen, and the emulsification time is 30 minutes to obtain the mixture emulsion C;

[0077] S4. Add 220 parts of water into the reaction kettle, maintain the nitrogen protection, stir and raise the temperature to within the range of 75°C;

[0078] S5. Transfer 1 / 5 part by weight of the mixture emulsion C to the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com