Self-healing binder for silicon-based negative electrode material for lithium battery, silicon-based negative electrode material for lithium battery, preparation method of silicon-based negative electrode material, negative electrode of battery and lithium battery

A silicon-based negative electrode material and lithium battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as internal structure damage and battery loss of function, and achieve good cycle performance and high initial Coulombic efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Still other embodiments of the present invention provide a method for preparing a silicon-based negative electrode material for a lithium battery described in the above embodiments, comprising the following steps:

[0038] Step 101: preparing an aqueous polyacrylic acid solution with a concentration of 45-55 mg / ml;

[0039] Step 102: Prepare an aqueous ferric chloride solution with a concentration of 5-15 mg / ml;

[0040] Step 103: Weigh the silicon-based material and conductive carbon black, put them into a container together with the above-mentioned ferric chloride aqueous solution and polyacrylic acid aqueous solution, stir and mix thoroughly to form a gel-like mixture, and prepare the silicon-based negative electrode material for lithium batteries.

[0041] In this preparation method, polyacrylic acid and Fe in the above binder are first 3+ Prepared into an aqueous solution, and then at room temperature, polyacrylic acid aqueous solution and Fe 3+ The aqueous solut...

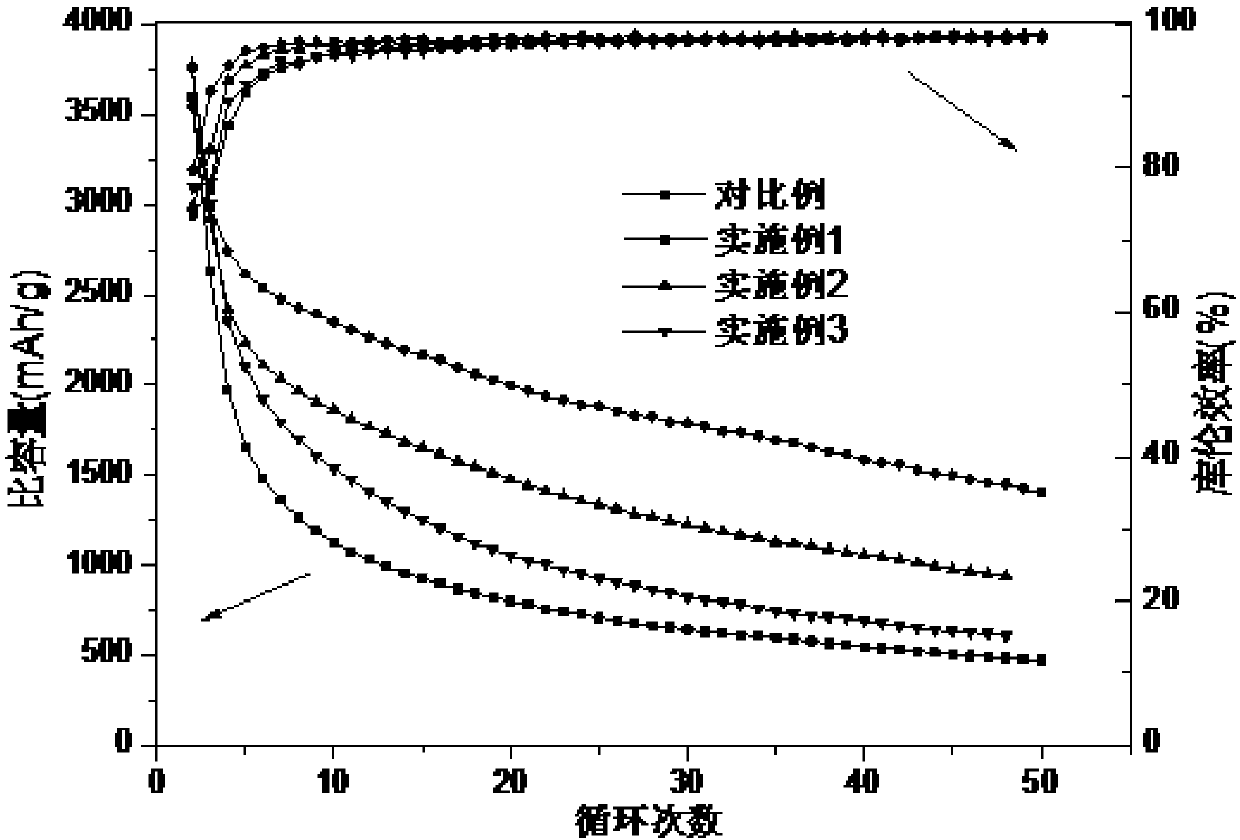

Embodiment 1

[0047] Prepare polyacrylic acid (PAA, Aladdin) aqueous solution 50mg / mL;

[0048] Preparation of ferric chloride (FeCl 3 , Aladdin) aqueous solution 10mg / mL;

[0049] Weigh 18mg of 1-5μm silicon powder, 6mg of Super-P conductive carbon black, FeCl 3 Add 14 μL of aqueous solution (2mol% vs acrylic acid) and 120 μL of PAA aqueous solution into an agate mortar, and stir well for 1 hour. Spread this gel-like mixture evenly on the treated Cu foil (150mm*100mm*9μm), dry it at room temperature for 2h, then place it in a vacuum oven, and dry it at 60°C for 12h. Cut the dried pole piece into a 7mm square. After weighing and calculating the mass of the active material on a single pole piece, vacuum dry at 60°C for 2 hours. The dried pole piece was moved to a glove box, and a lithium piece was used as a counter electrode to assemble a 2032 button cell. The electrolyte is 1M lithium hexafluorophosphate (LiPF 6 , Aladdin) is a ethylene carbonate / dimethyl carbonate (EC / DMC, Aladdin) s...

Embodiment 2

[0051] Prepare polyacrylic acid (PAA, Aladdin) aqueous solution 50mg / mL;

[0052] Preparation of ferric chloride (FeCl 3 , Aladdin) aqueous solution 10mg / mL;

[0053] Weigh 18mg of 1-5μm silicon powder, 6mg of Super-P conductive carbon black, FeCl 3 Add 7 μL of aqueous solution (1 mol% vs acrylic acid) and 120 μL of PAA aqueous solution into an agate mortar, and stir well for 1 hour. Spread this gel-like mixture evenly on the treated Cu foil (150mm*100mm*9μm), dry it at room temperature for 2h, then place it in a vacuum oven, and dry it at 60°C for 12h. Cut the dried pole piece into a 7mm square. After weighing and calculating the mass of the active material on a single pole piece, vacuum dry at 60°C for 2 hours. The dried pole piece was moved to a glove box, and a lithium piece was used as a counter electrode to assemble a 2032 button cell. The electrolyte is 1M lithium hexafluorophosphate (LiPF 6 , Aladdin) is a ethylene carbonate / dimethyl carbonate (EC / DMC, Aladdin) s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Charge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com