A graphene-wrapped molybdenum carbide/carbon microsphere electrocatalyst and its preparation method and its application in hydrogen production by electrolysis of water under acidic conditions

An electrocatalyst, graphene technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, chemical instruments and methods, etc., can solve the problems of reduced specific surface area, unfavorable practical application, complex preparation method, etc., to reduce adsorption. energy, accelerated charge transfer rate, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

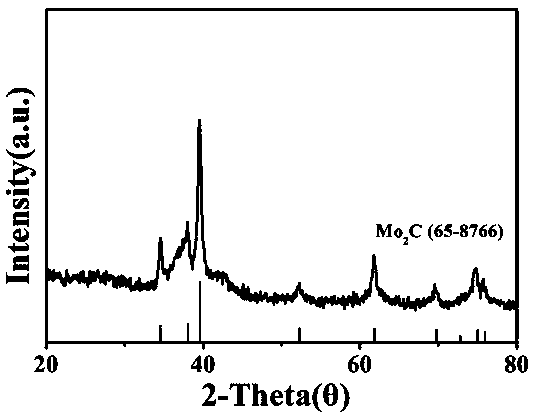

[0027] Sample preparation: Dissolve 1g molybdate and 14mL 7.2mg / mL graphene oxide in 28mL deionized water, dissolve 1g chitosan in a mixed solvent of 2mL acetic acid and 186mL deionized water, and then mix the two solutions , Stirring at a speed of 500-1600 r / min. The mixed solution is spray-dried, and the temperature is set to 100~130℃ during spray drying, and the sampling speed is 4~6mL / min. Then the solid powder is collected and annealed at a high temperature under argon atmosphere. The temperature is raised to 750℃ for 6 hours, and the temperature is kept warm. After 3 hours of natural cooling, graphene-wound molybdenum carbide / carbon microsphere electrocatalyst was obtained.

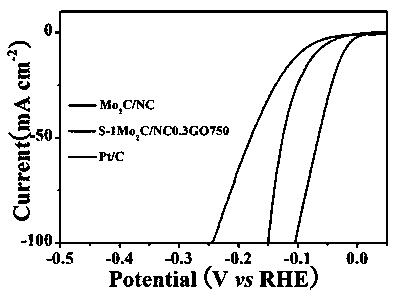

[0028] Electrocatalytic application: 2mg of sample and 1mg of conductive carbon are dissolved in 500μL of alcohol-water mixture and mixed uniformly by ultrasound to form a black suspension. Pipette 10μL of the suspension onto the glassy carbon electrode, dry it naturally and then drop it. Add 5μL of N...

Embodiment 2

[0030] Sample preparation: Dissolve 1g molybdate and 42mL7.2mg / mL graphene oxide in 28mL deionized water, dissolve 1g chitosan in a mixed solvent of 2mL acetic acid and 158mL deionized water, and then mix the two solutions , Stirring at a speed of 500-1600 r / min. The mixed solution is spray-dried, and the temperature is set to 100~130°C during spray drying, and the sampling speed is 4~6mL / min. Then, the solid powder is collected, annealed at a high temperature under argon atmosphere, and heated to 750°C for 6 hours, and kept warm. After 3 hours of natural cooling, the graphene-wound molybdenum carbide / carbon microsphere electrocatalyst was obtained.

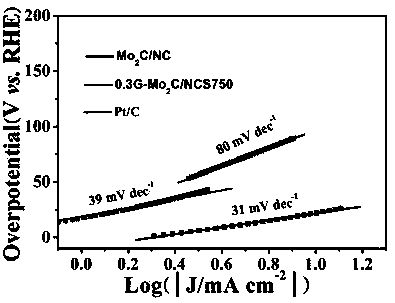

[0031] Electrocatalysis application: preparation and testing of electrodes are the same as in Example 1. The current density of the sample is 10mA / cm 2 When the overpotential is 70mV. This sample has the best electrocatalytic performance.

Embodiment 3

[0033] Sample preparation: Dissolve 1g molybdate and 70mL7.2mg / mL graphene oxide in 28mL deionized water, dissolve 1g chitosan in a mixed solvent of 2mL acetic acid and 130mL deionized water, and then mix the two solutions , Stirring at a speed of 500-1600 r / min. The mixed solution is spray-dried, and the temperature is set to 100~130°C during spray drying, and the sampling speed is 4~6mL / min. Then, the solid powder is collected, annealed at a high temperature under argon atmosphere, and heated to 750°C for 6 hours, and kept warm. After 3 hours of natural cooling, the graphene-wound molybdenum carbide / carbon microsphere electrocatalyst was obtained.

[0034] Electrocatalysis application: preparation and testing of electrodes are the same as in Example 1. The current density of the sample is 10mA / cm 2 When the overpotential is 96mV.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com