A phase transfer catalyst used for cyclohexanol oxidation to synthesize cyclohexanone and a preparing method thereof

A phase transfer catalyst, oxidative synthesis technology, applied in the preparation of organic compounds, preparation of carbon-based compounds, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problems of low catalyst activity and poor reusability, etc. Achieve high specific surface area, low mass transfer resistance, and avoid poor high temperature performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

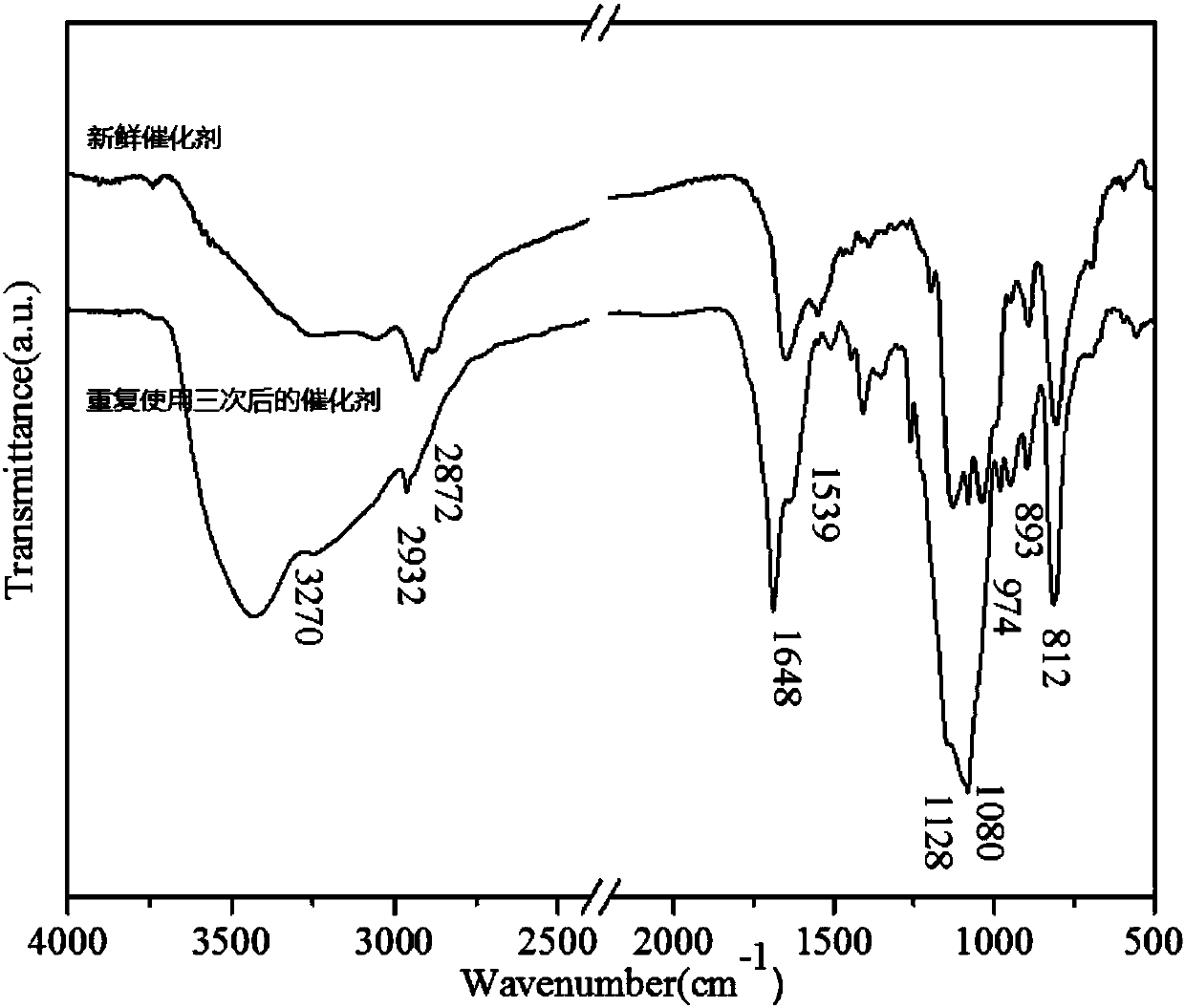

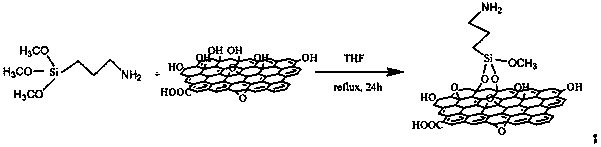

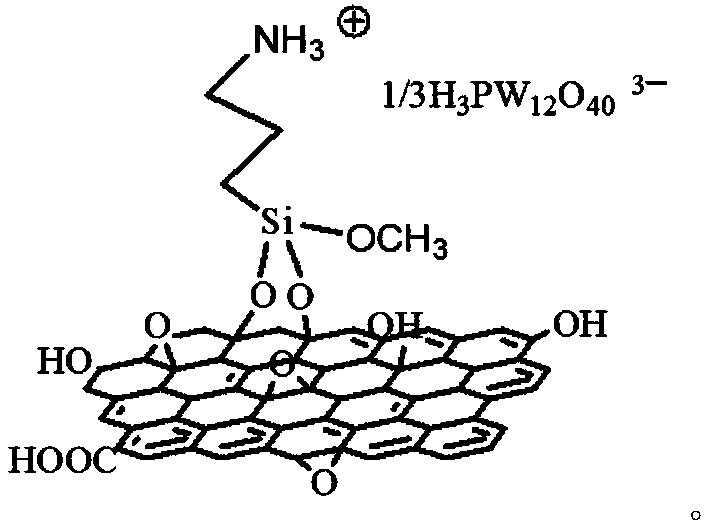

[0023] In tetrahydrofuran, graphene oxide and 3-aminopropyltrimethoxysilane silane were mixed, wherein the mass ratio of graphene oxide and 3-aminopropyltrimethoxysilane was 1:5, magnetically stirred under nitrogen protection, Reflux for 12 hours in an oil bath at 80°C. It was then filtered, washed with ethanol, and the resulting solid was dried under vacuum at 60 °C for 12 h. Put the obtained solid substance and phosphotungstic acid into an agate mortar, in which the mass ratio of solid to phosphotungstic acid is 2:1, fully grind for 1 hour at room temperature, and wait until the mixture becomes a gray powder and stops, which is the desired phase. The transfer catalyst is denoted as CAT1.

Embodiment 2

[0025] In tetrahydrofuran, graphene oxide and 3-aminopropyltrimethoxysilane were mixed, wherein the mass ratio of graphene oxide to 3-aminopropyltrimethoxysilane was 1:10, magnetic stirring under nitrogen protection, 100 Reflux for 12 hours in an oil bath at ℃. It was then filtered, washed with ethanol, and the resulting solid was dried under vacuum at 60 °C for 12 h. Put the obtained solid substance and phosphotungstic acid into an agate mortar, in which the mass ratio of the solid to phosphotungstic acid is 1:1, and fully grind for 1 hour at room temperature, until the mixture becomes a gray powder and stops, which is the desired phase. The transfer catalyst is denoted as CAT2.

Embodiment 3

[0027] In tetrahydrofuran, graphene oxide and 3-aminopropyltrimethoxysilane were mixed, wherein the mass ratio of graphene oxide to 3-aminopropyltrimethoxysilane was 1:8, magnetic stirring under nitrogen protection, 90 Reflux in an oil bath for 24 hours. It was then filtered, washed with ethanol, and the resulting solid was dried under vacuum at 60 °C for 12 h. Put the obtained solid substance and phosphotungstic acid into an agate mortar, in which the mass ratio of solid to phosphotungstic acid is 2:1, fully grind for 1 hour at room temperature, and wait until the mixture becomes a gray powder and stops, which is the desired phase. The transfer catalyst is denoted as CAT3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com