Magnetic dendritic polymer composite nanoparticle, and preparation method and application thereof

A composite nanoparticle and nanoparticle technology, applied in the field of magnetic dendritic polymer composite magnetic nanoparticles and their preparation, and magnetic dendritic polymer composite magnetic nanoparticles, can solve the problem of poor recycling effect, poor material stability, solid loading problems such as low capacity, to achieve the effect of increasing immobilization capacity, fewer synthesis steps, and enhanced condition tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

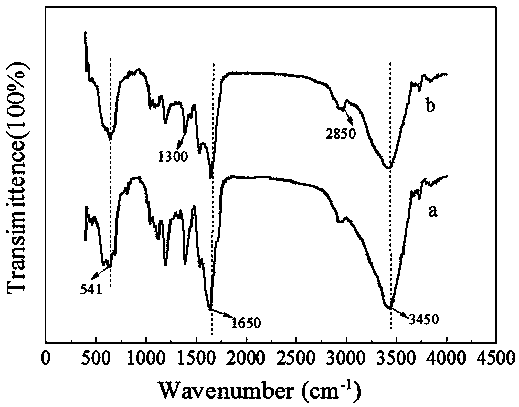

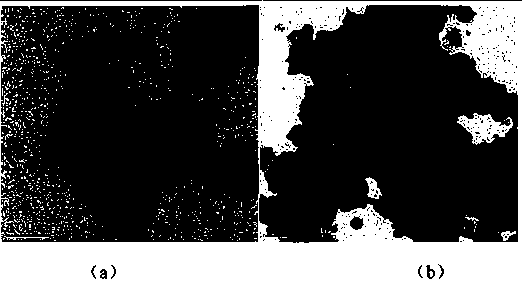

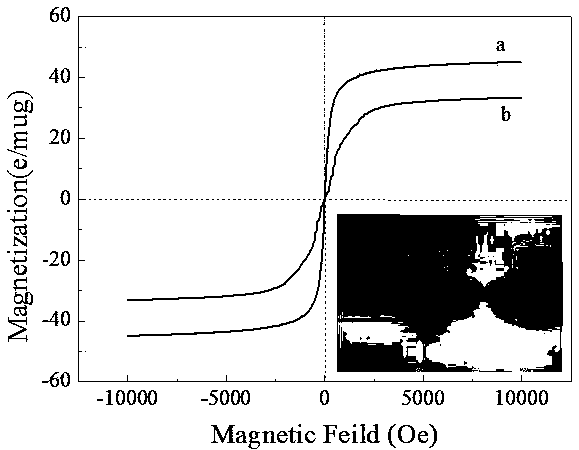

[0044] Embodiment 1: Amino-modified iron ferric oxide nanoparticles Fe 3 o 4 -NH 2 Synthesis

[0045] 1 g FeCl 3 •6H 2 O was ultrasonically dissolved in 30 mL of ethylene glycol solution, placed in a water bath with magnetic stirring turned on, and 2 g of sodium acetate was added to continue stirring at 500 r / min for 30 min. Pour the solution into a beaker, add 6.5 g of 1,6-ethylenediamine and stir. The obtained red solution was poured into a polytetrafluoroethylene-lined autoclave, and then put into a high-temperature oven at 160 °C after tightening, and taken out after high-temperature reaction for 3 h. After the autoclave had cooled, the Teflon liner was removed and the product was transferred to a beaker. Then use a Buchner funnel to carry out suction filtration to obtain black granular particles, wash with absolute ethanol, then clean with deionized water, and finally carry out solid-liquid separation with a centrifuge, and pour out the black product obtained after ...

Embodiment 2

[0046] Embodiment 2: Amino-modified iron ferric oxide nanoparticles Fe 3 o 4 -NH 2 Synthesis

[0047] 2 g FeCl 3 •6H 2 O was ultrasonically dissolved in 60 mL of ethylene glycol solution, placed in a water bath with magnetic stirring turned on, and 4 g of sodium acetate was added to continue stirring at 800 r / min for 30 min. Pour the solution into a beaker, add 13 g of 1,6-ethylenediamine and stir. The obtained red solution was poured into a polytetrafluoroethylene-lined autoclave, tightened and placed in a high-temperature oven at 198 °C for 6 h after high-temperature reaction. After the autoclave had cooled, the Teflon liner was removed and the product was transferred to a beaker. Then use a Buchner funnel to carry out suction filtration to obtain black granular particles, wash with absolute ethanol, then clean with deionized water, and finally carry out solid-liquid separation with a centrifuge, and pour out the black product obtained after the supernatant. into an e...

Embodiment 3

[0048] Embodiment 3: the iron ferric oxide nanoparticles Fe of amino modification 3 o 4 -NH 2 Synthesis

[0049] 5 g FeCl 3 •6H 2 O was ultrasonically dissolved in 150 mL of ethylene glycol solution, placed in a water bath with magnetic stirring turned on, and 6 g of sodium acetate was added to continue stirring at 1000 r / min for 30 min. Pour the solution into a beaker, add 30 g of 1,6-ethylenediamine and stir. The obtained red solution was poured into a polytetrafluoroethylene-lined autoclave, and then put into a high-temperature oven at 250 °C after tightening, and taken out after high-temperature reaction for 12 h. After the autoclave had cooled, the Teflon liner was removed and the product was transferred to a beaker. Then use a Buchner funnel to carry out suction filtration to obtain black granular particles, wash with absolute ethanol, then clean with deionized water, and finally carry out solid-liquid separation with a centrifuge, and pour out the black product ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific vitality | aaaaa | aaaaa |

| Specific vitality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com